2019 Challenger Widebooty HellKitty (she's giving me the meatsweats...)

- Thread starter motorheadmike

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

It's even the right color....

the only way to not park in a space

First of the flapper valves came in. The other one is doing the literal hot lap around Western Canada.

This thing opens lightening fast! Startled me. I'd almost put it on a Hobbs switch once it senses boost it flips open. Decisions. Decisions.

This thing opens lightening fast! Startled me. I'd almost put it on a Hobbs switch once it senses boost it flips open. Decisions. Decisions.

I like this logic.First of the flapper valves came in. The other one is doing the literal hot lap around Western Canada.

View attachment 179115

This thing opens lightening fast! Startled me. I'd almost put it on a Hobbs switch once it senses boost it flips open. Decisions. Decisions.

First of the flapper valves came in. The other one is doing the literal hot lap around Western Canada.

View attachment 179115

This thing opens lightening fast! Startled me. I'd almost put it on a Hobbs switch once it senses boost it flips open. Decisions. Decisions.

Who’s is it?? (Manufacturer)

Who’s is it?? (Manufacturer)

Sum Yung Giah from Chy-nah.

Had to order them from two seperate sellers. Since at the time each only had one available.

Aramox Exhaust Valve Control for E82 E88 F2X F3X, Electric Control Exhaust Valve Cutout Low Pressure for Catback Downpipe(D76 for 3in Piping) : Amazon.ca: Automotive

Aramox Exhaust Valve Control for E82 E88 F2X F3X, Electric Control Exhaust Valve Cutout Low Pressure for Catback Downpipe(D76 for 3in Piping) : Amazon.ca: Automotive

www.amazon.ca

Sum Yung Giah from Chy-nah.

Had to order them from two seperate sellers. Since at the time each only had one available.

Aramox Exhaust Valve Control for E82 E88 F2X F3X, Electric Control Exhaust Valve Cutout Low Pressure for Catback Downpipe(D76 for 3in Piping) : Amazon.ca: Automotive

Aramox Exhaust Valve Control for E82 E88 F2X F3X, Electric Control Exhaust Valve Cutout Low Pressure for Catback Downpipe(D76 for 3in Piping) : Amazon.ca: Automotivewww.amazon.ca

Sweet. I’ve got the Dougs Headers sliding knife version on The Juggernaut. I’d be interested to see how each holds up long term.

I’ve heard that the flapper valve style like you have can suffer from sealing issues once they get a bit carboned up.

Sweet. I’ve got the Dougs Headers sliding knife version on The Juggernaut. I’d be interested to see how each holds up long term.

I’ve heard that the flapper valve style like you have can suffer from sealing issues once they get a bit carboned up.

I am drilling holes in them since they are inline, not cutouts, so it shouldn't be an issue.

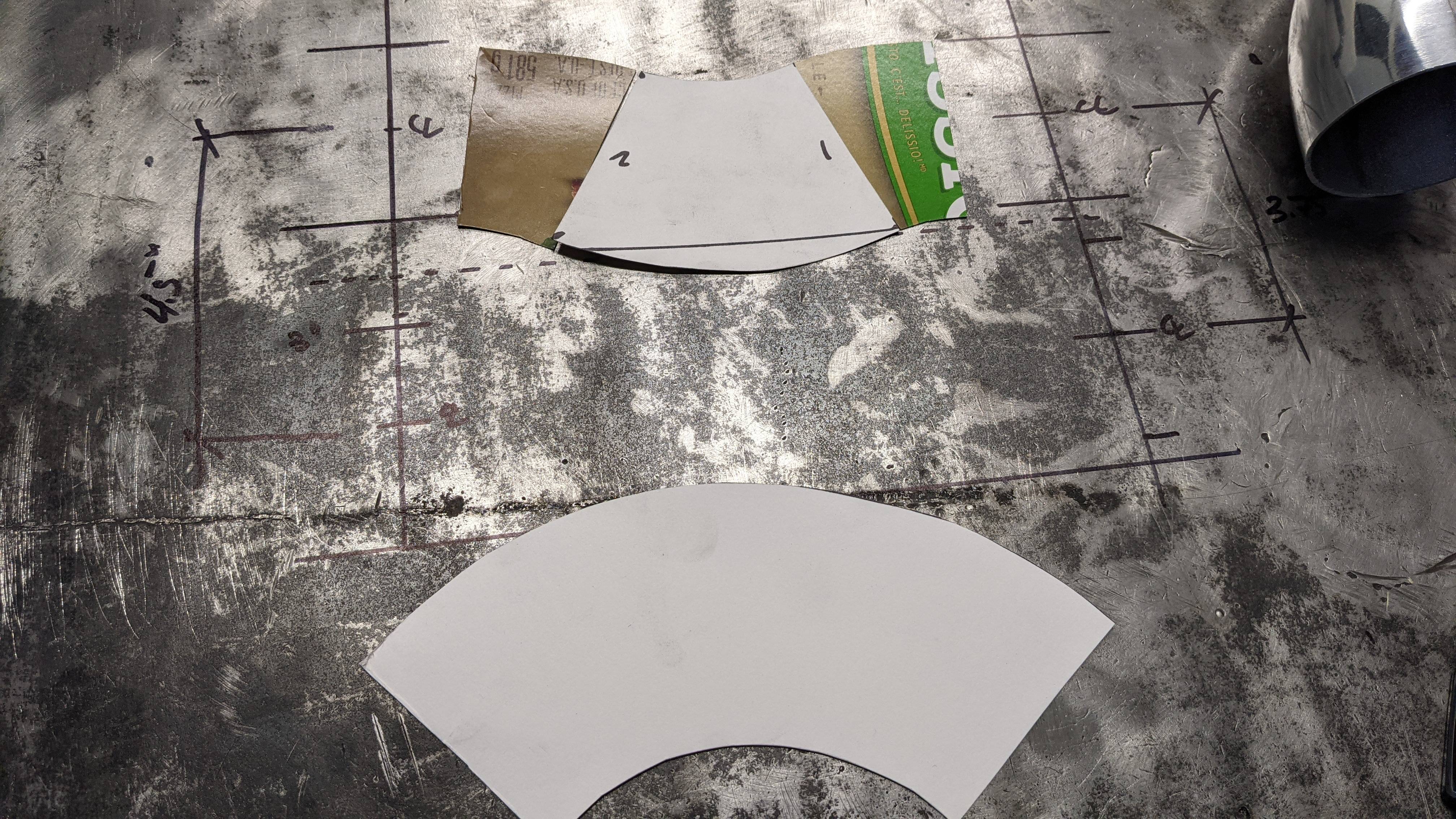

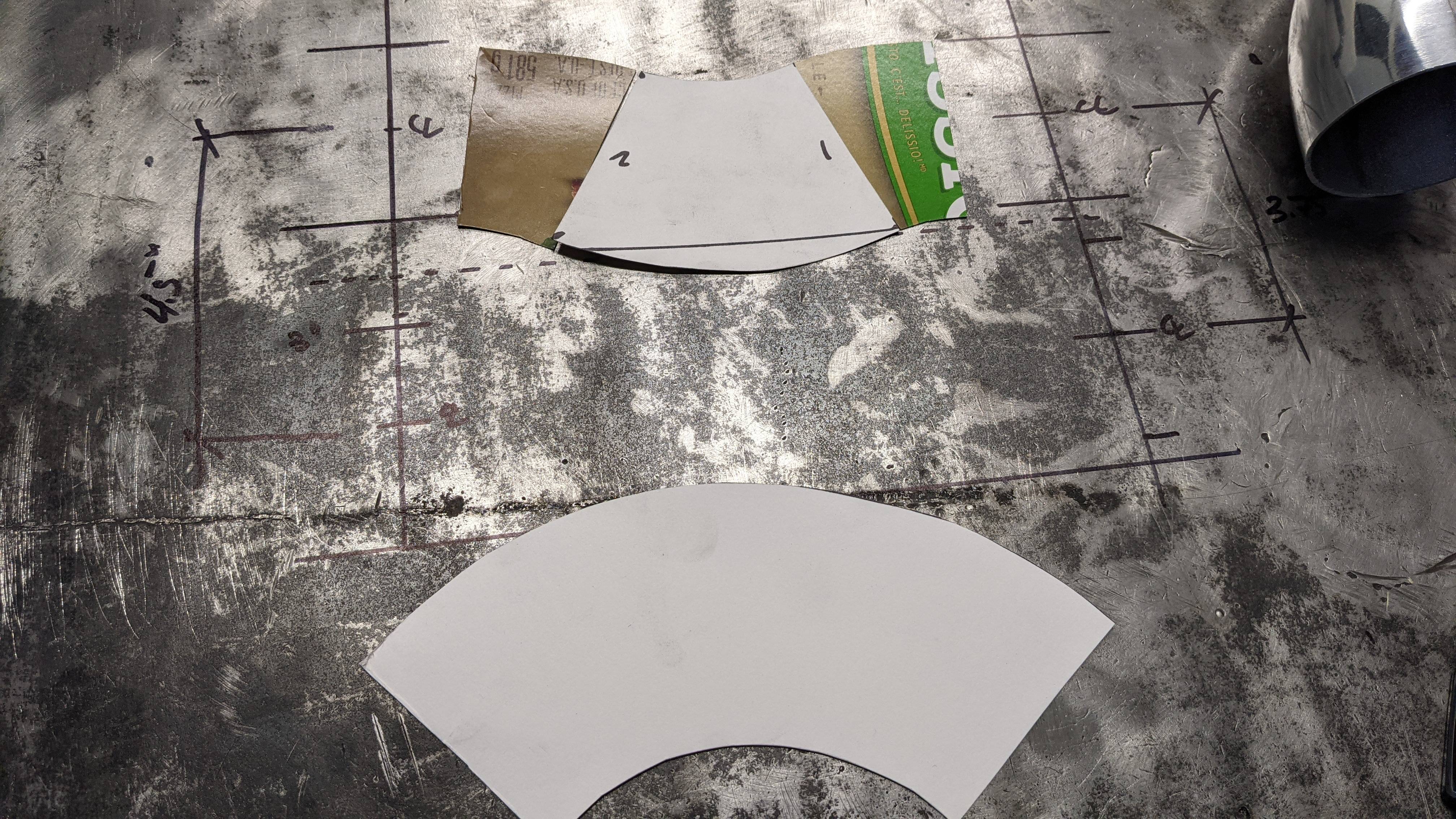

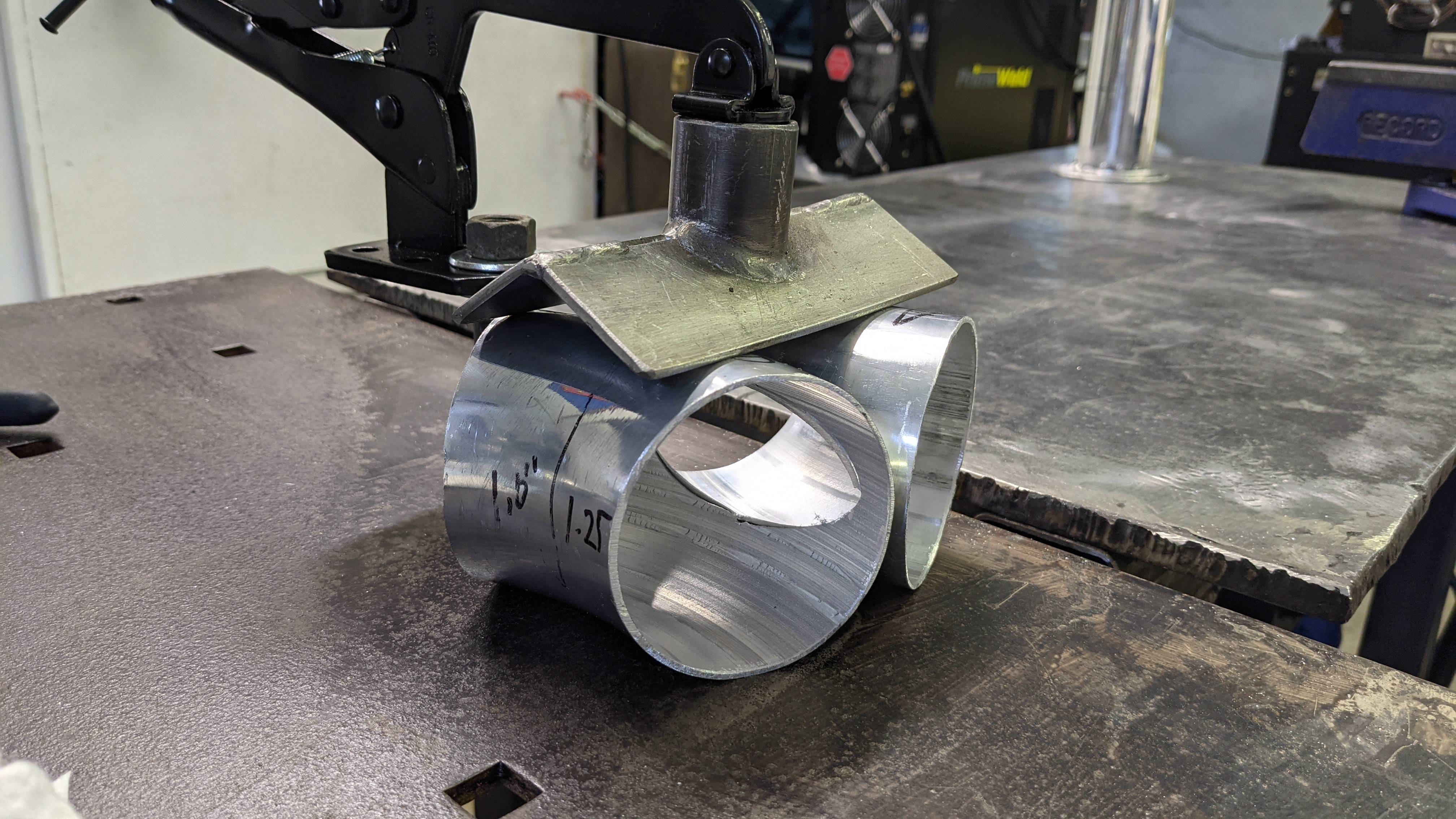

Got the day off from course. So I decided to start plotting out the x-pipe.

Last edited:

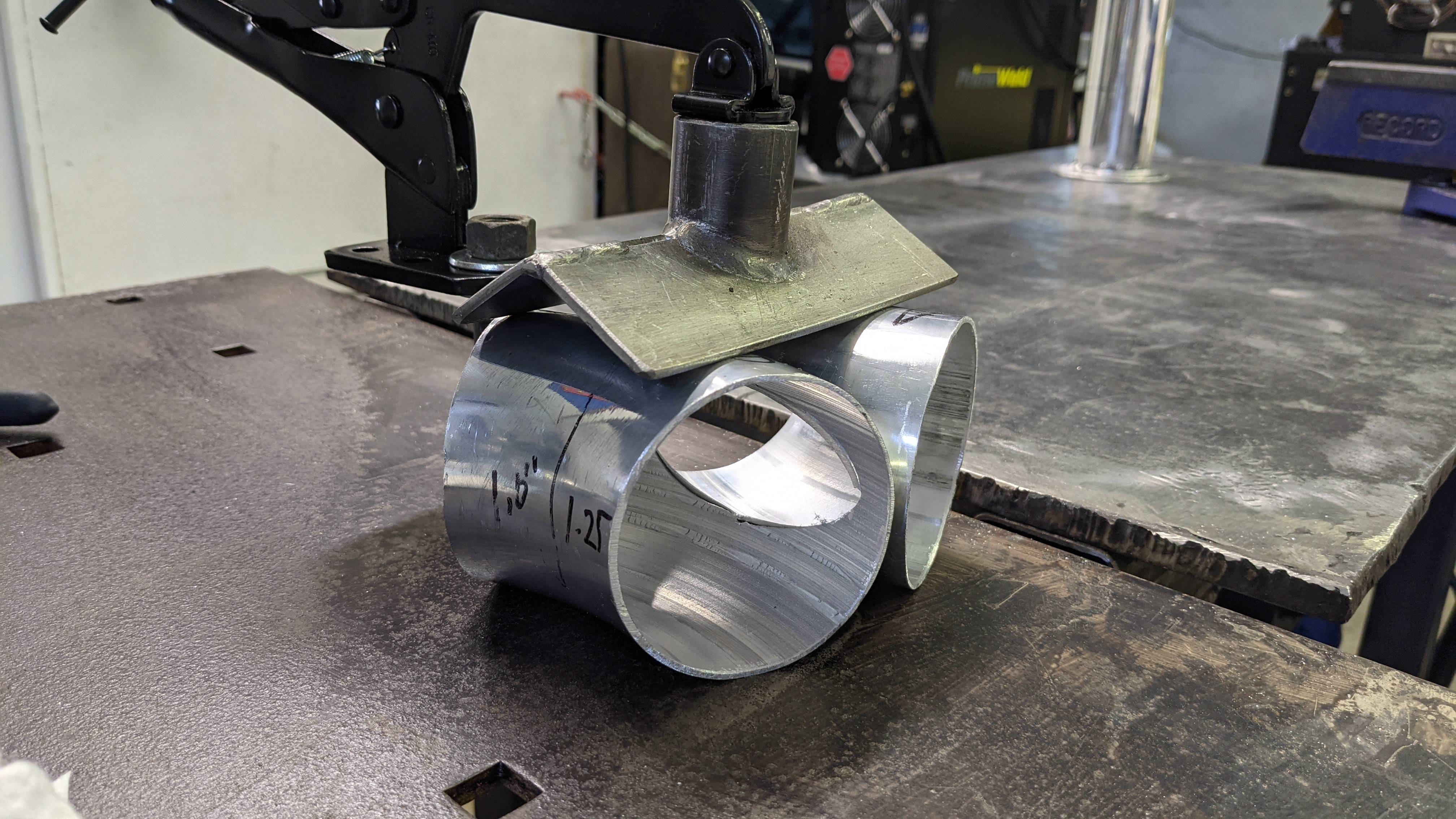

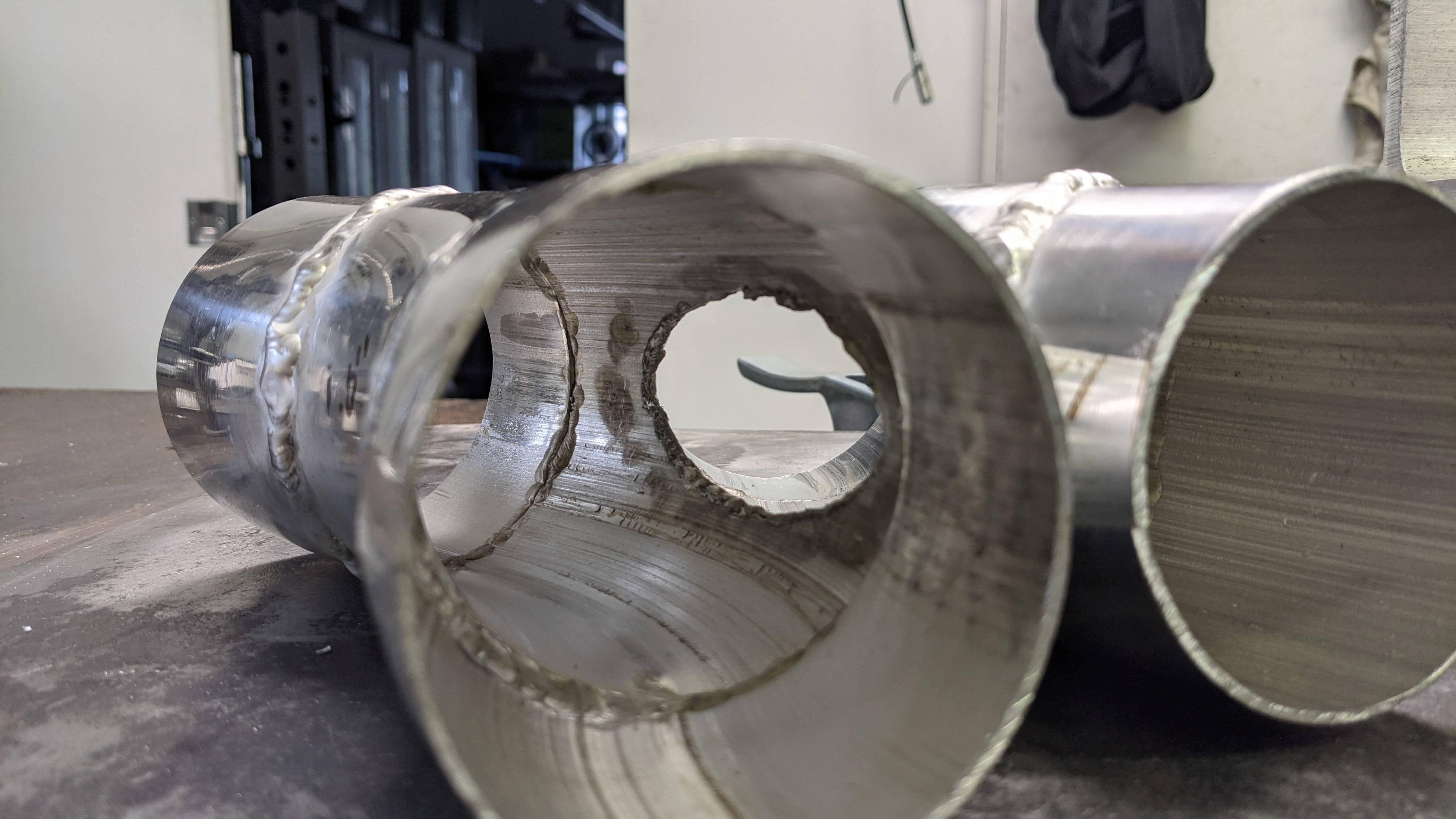

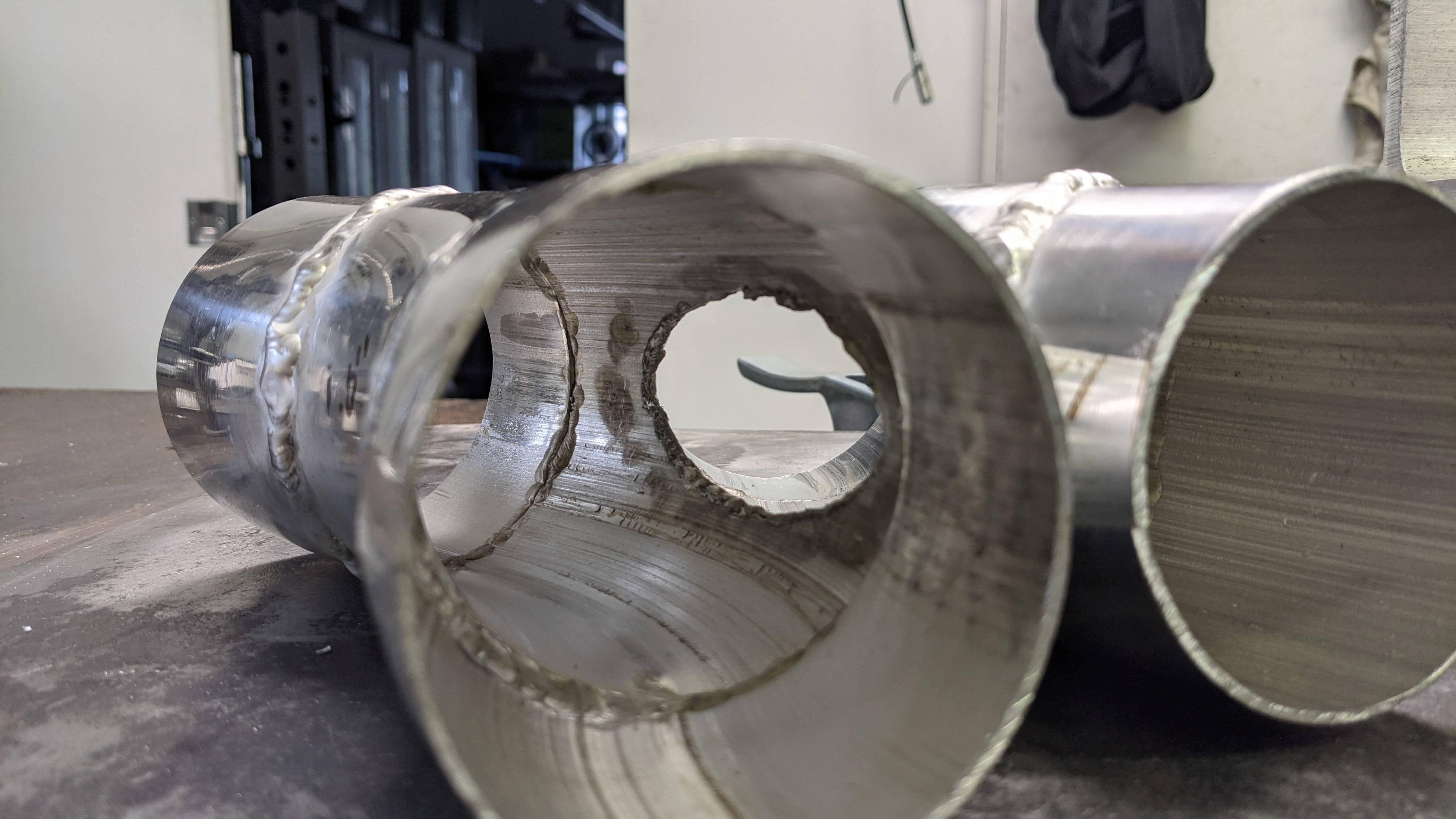

Well this was a PITA to build. Especially the tight pinch points.

Fusion (cold) welded the inside of the two mating pipes to make it easier to assemble. Worked out surprisingly well using a stubby #5 and back cap.

The goal was to have the inlet side 3.75" CL to CL, and the exit at 4.5" CL to CL. It was also made deliberately asymmetrical as the stock pipes are askew, favouring the PS if I remember correctly. The new mufflers are good being angled since the cars come with either bullets or case mufflers and there is lots of space.

Overal the fit-up was so-so, so the welds came out a little inconsistent. I also I am pretty f*cking tired. I will probably go over the inside with a penetrating pass to ensure... err... penetration. I will also be adding a brace between the two connected pipes.

One step closer.

Fusion (cold) welded the inside of the two mating pipes to make it easier to assemble. Worked out surprisingly well using a stubby #5 and back cap.

The goal was to have the inlet side 3.75" CL to CL, and the exit at 4.5" CL to CL. It was also made deliberately asymmetrical as the stock pipes are askew, favouring the PS if I remember correctly. The new mufflers are good being angled since the cars come with either bullets or case mufflers and there is lots of space.

Overal the fit-up was so-so, so the welds came out a little inconsistent. I also I am pretty f*cking tired. I will probably go over the inside with a penetrating pass to ensure... err... penetration. I will also be adding a brace between the two connected pipes.

One step closer.

Last edited:

- Status

- Not open for further replies.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.