I broke down my El Camino/Monte Carlo front clip/500 Caddy conversion at the request of a couple to make it a bit easier to read. The first 2 parts covered the body work portion and 9 in Ford rearend setup.

viewtopic.php?f=41&t=25429

viewtopic.php?f=14&t=25389

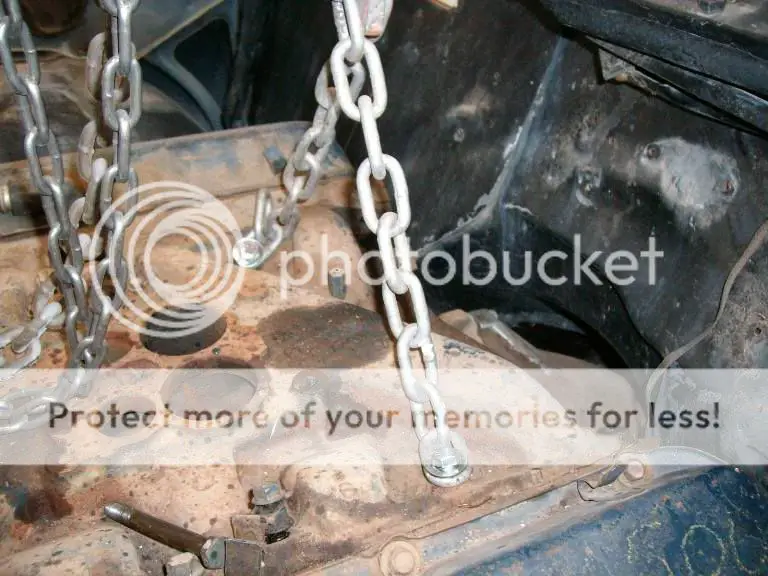

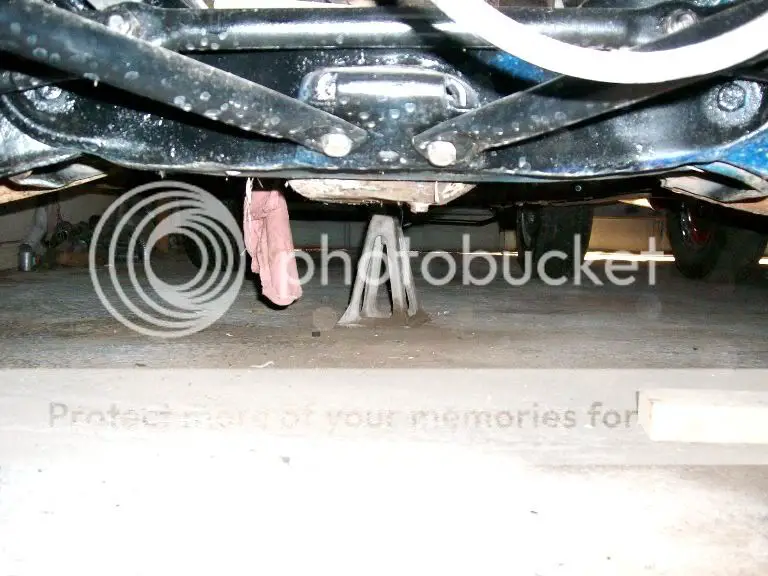

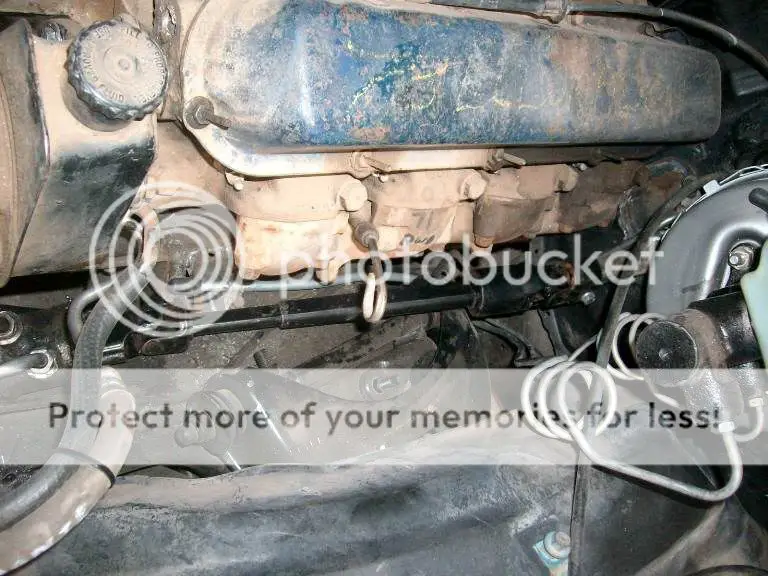

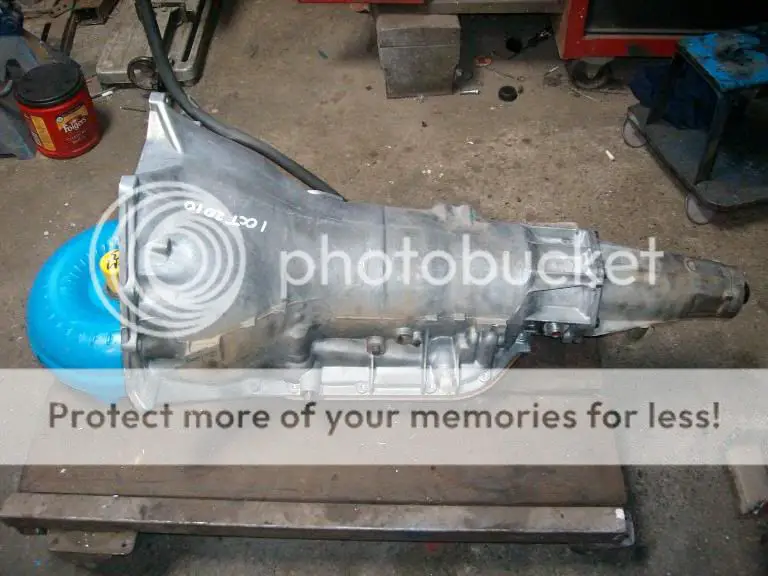

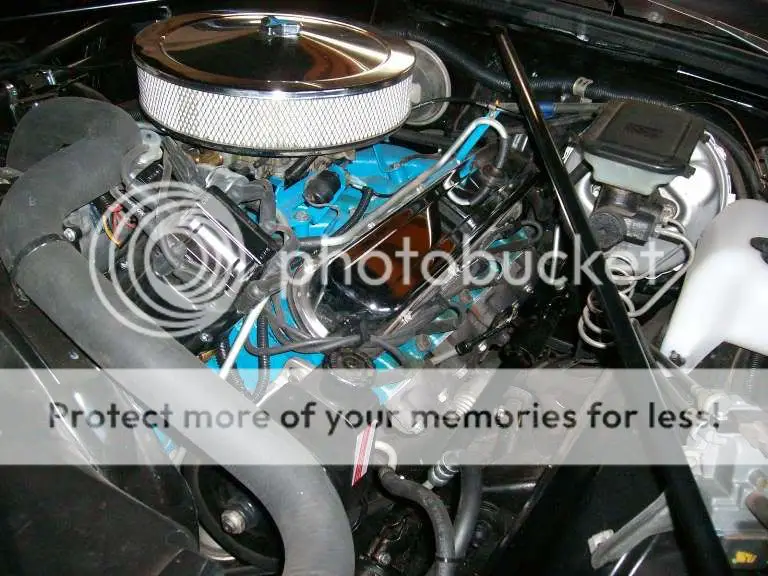

This thread will cover the 500 Cadillac/TH400 swap portion of the build. As the engine compartments of the G Bodies are virtually identical this should pretty much apply to stuffing a caddy motor into any of them. This is the way I installed the engine and transmission in my swap and is definitely not the only way to do it. There are different engine mount kits out there (or a person could build his own), different crossmembers and different ways of routing exhaust etc......this is just how it worked out for me.

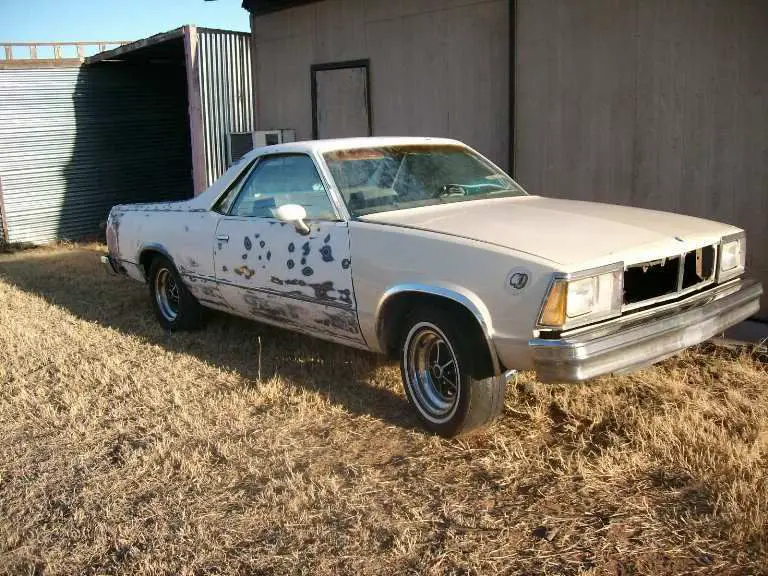

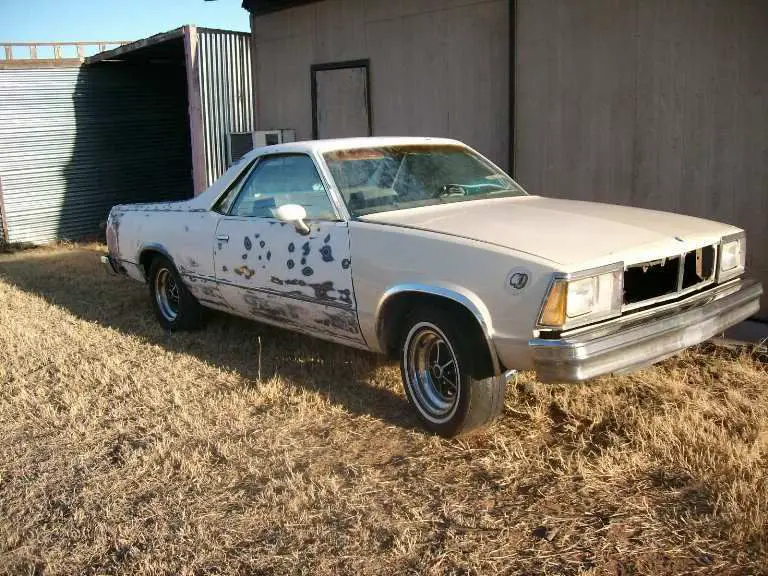

The whole project petty much came about because I had a 500 Cadillac engine I picked up years ago and was waiting around for the right project to stuff it in.......it turned out to be an 83 El Camino parts truck I ended up with.

I bought the El Camino as a parts truck and even though the guy said he had a title for it it ended up taking a couple of months to get it in my hands (and I sure wasn’t going to start a project this involved and expensive without legally owning the vehicle). While I was waiting on him, I went ahead and took care of a couple of things on the motor.

The first thing I addressed was the pulleys. The majority of the 60s/70s 472s and 500s used a system that REQUIRED a smog pump (the pump is driven by the crank pulley and it in turn drives the water pump).

I got lucky and scored the 1970 only non-smog pump set up.

The other option would have been to try to find a late 70’s 425 powered Cadillac which ran a similar set up but with a single AC/PS belt.

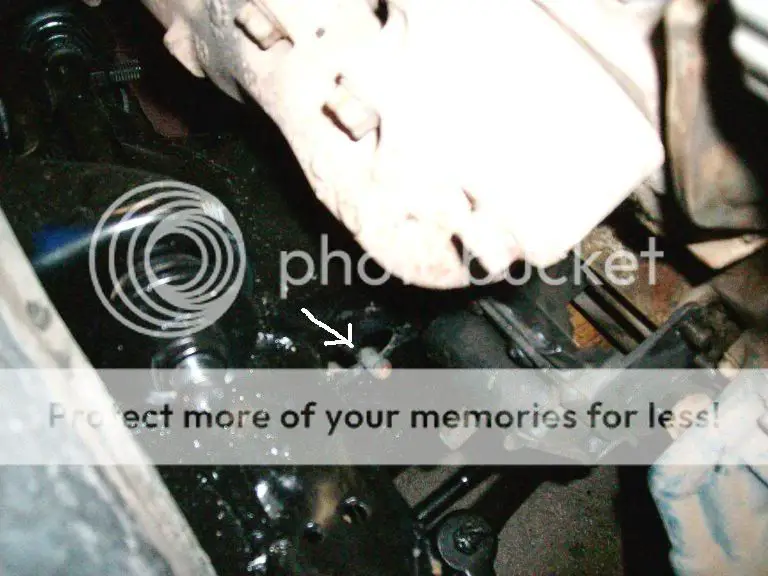

The only stock pan that will work with this swap is the rear sump El Dorado pan and as my engine came from an Eldo I had the right one. One of the potential issues with using this pan is that it is a dual sump unit with 2 drain plugs. The front sump holds about 1 Qt of oil and needs to be drained during oil changes etc. The problem when using it in a G Body is that the front plug sits right over the crossmember and depending on how low you set the engine the plug can be inaccessible or at the very least very messy to change oil.

The ridge that forms the front sump and holds the oil is for front axel clearance (the Eldos were FWD with a transaxle). I decided to eliminated the front sump holding oil by heating the ridge and then using a piece of pipe over the heated area and hammering the ridge down to provide a way for the oil to drain back to the main sump.

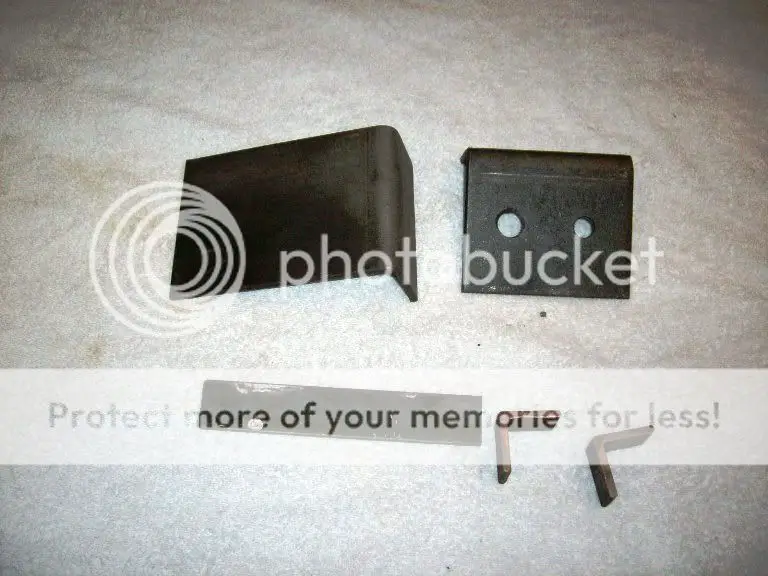

The final thing I did while waiting on the title was to convert from the old A6 AC compressor to the smaller Sanden 508 style. They do make a bracket set to do this (at about $100), but when I started checking around no one actually had one on the shelf. After studying the A6 bracket for a while, I figured out I could simply enlarge the saddle area, elongate the holes, and build a simple rear bracket to mount the Sanden. It worked great and the belts lined up perfectly.

viewtopic.php?f=41&t=25429

viewtopic.php?f=14&t=25389

This thread will cover the 500 Cadillac/TH400 swap portion of the build. As the engine compartments of the G Bodies are virtually identical this should pretty much apply to stuffing a caddy motor into any of them. This is the way I installed the engine and transmission in my swap and is definitely not the only way to do it. There are different engine mount kits out there (or a person could build his own), different crossmembers and different ways of routing exhaust etc......this is just how it worked out for me.

The whole project petty much came about because I had a 500 Cadillac engine I picked up years ago and was waiting around for the right project to stuff it in.......it turned out to be an 83 El Camino parts truck I ended up with.

I bought the El Camino as a parts truck and even though the guy said he had a title for it it ended up taking a couple of months to get it in my hands (and I sure wasn’t going to start a project this involved and expensive without legally owning the vehicle). While I was waiting on him, I went ahead and took care of a couple of things on the motor.

The first thing I addressed was the pulleys. The majority of the 60s/70s 472s and 500s used a system that REQUIRED a smog pump (the pump is driven by the crank pulley and it in turn drives the water pump).

I got lucky and scored the 1970 only non-smog pump set up.

The other option would have been to try to find a late 70’s 425 powered Cadillac which ran a similar set up but with a single AC/PS belt.

The only stock pan that will work with this swap is the rear sump El Dorado pan and as my engine came from an Eldo I had the right one. One of the potential issues with using this pan is that it is a dual sump unit with 2 drain plugs. The front sump holds about 1 Qt of oil and needs to be drained during oil changes etc. The problem when using it in a G Body is that the front plug sits right over the crossmember and depending on how low you set the engine the plug can be inaccessible or at the very least very messy to change oil.

The ridge that forms the front sump and holds the oil is for front axel clearance (the Eldos were FWD with a transaxle). I decided to eliminated the front sump holding oil by heating the ridge and then using a piece of pipe over the heated area and hammering the ridge down to provide a way for the oil to drain back to the main sump.

The final thing I did while waiting on the title was to convert from the old A6 AC compressor to the smaller Sanden 508 style. They do make a bracket set to do this (at about $100), but when I started checking around no one actually had one on the shelf. After studying the A6 bracket for a while, I figured out I could simply enlarge the saddle area, elongate the holes, and build a simple rear bracket to mount the Sanden. It worked great and the belts lined up perfectly.