There's only a handful of people I would consider experts. I'm not one of them. At least you're not doing a dual crankshaft timing pinion setup on a Fairbanks-Morse 8-1/8 6 cylinder opposed piston diesel engine. Those ring gears were measured in feet. Same type of mesh checking though. Just larger. And no chance of coast side mesh.

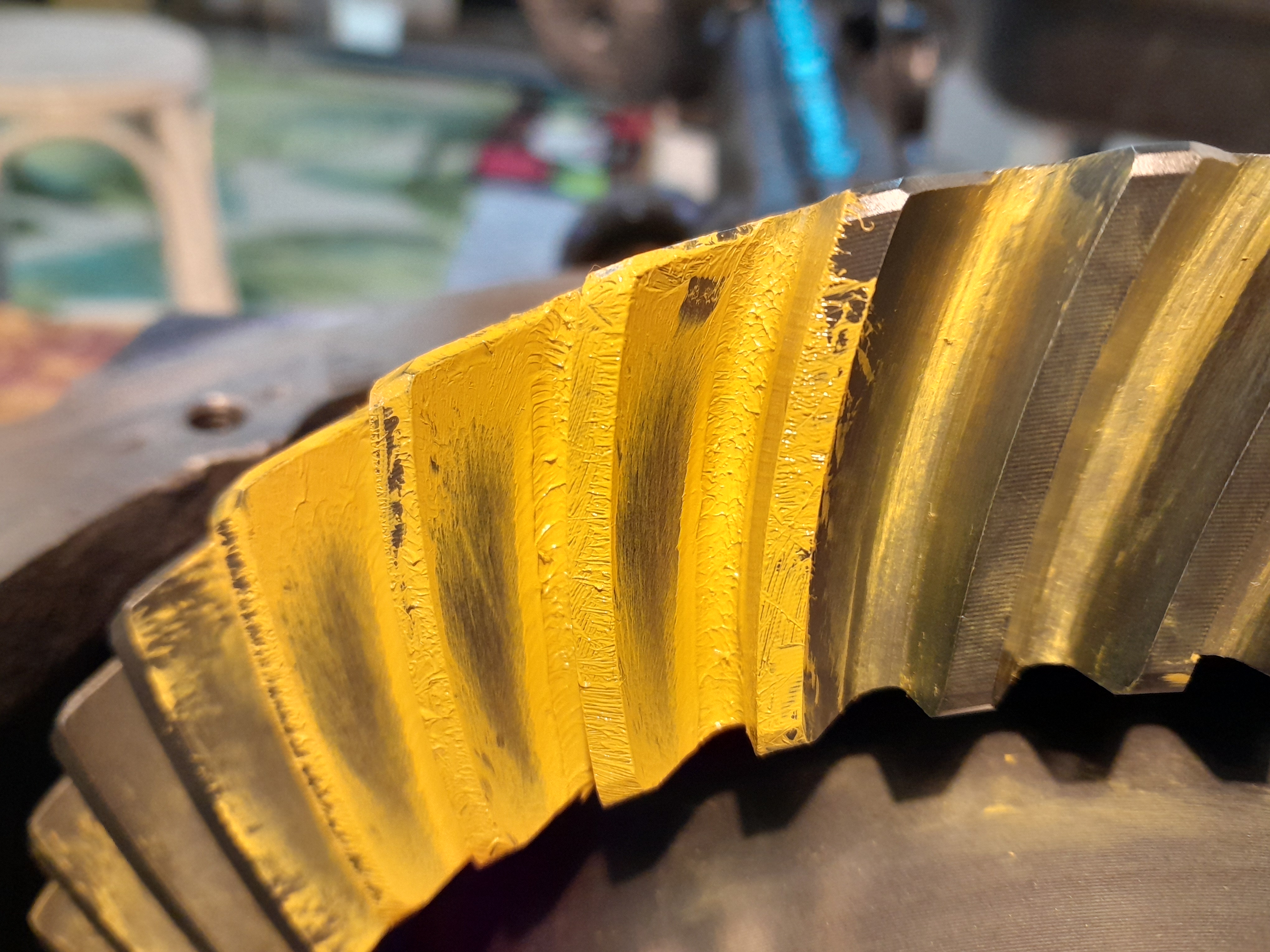

I've learned over the years that experts tend to come to a consensus that the pattern on the coast side pattern isn't a major factor. It's the drive side that matters. Obviously, you want the coast side to have good engagement, too, but it's not as critical to be "perfect" on the coast as it is the drive. I've heard and read that in different places. Again, I'm no expert. If it's important to you is all that matters.

It is my opinion that your 0.038 is the "best" of the three as far as engagement. The 0.035 seems way too close to the face, or top of the teeth, for me.

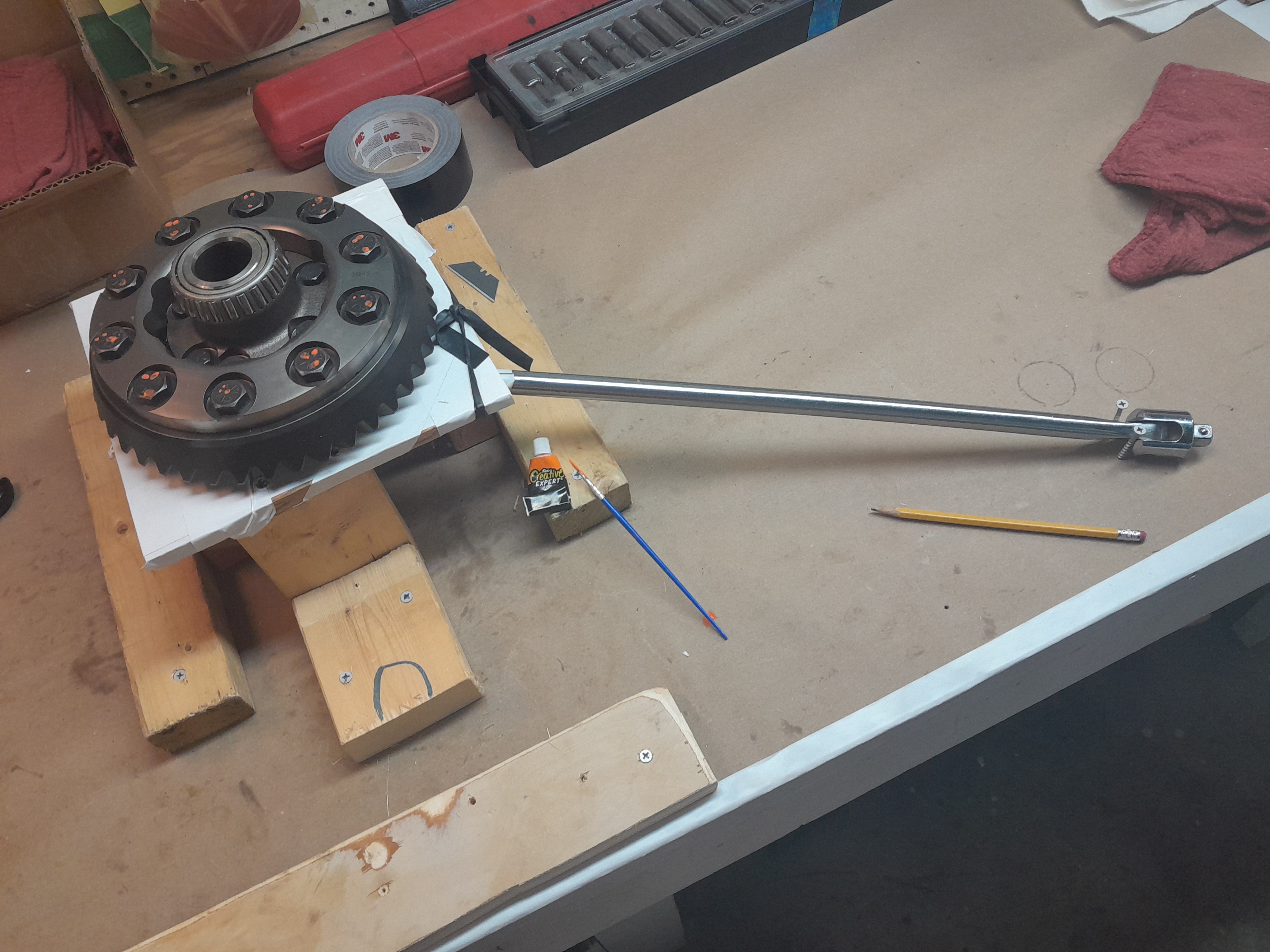

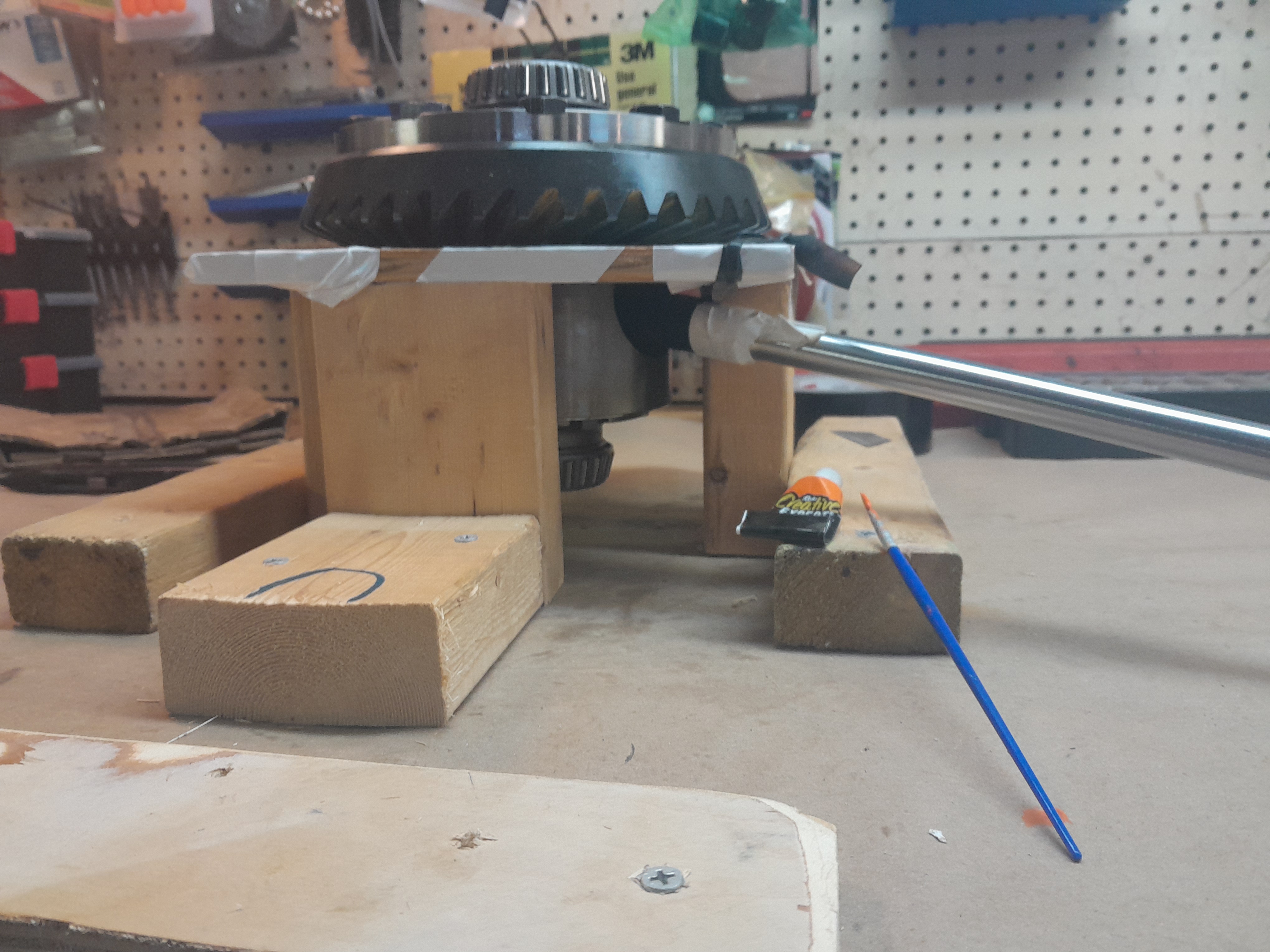

The 0.038 and 0.042 seems to me more the way to go. Although the 0.038 appears acceptable on the drive side, you seem a bit close to the heel on the coast side, but not too deep. I'd lean to the 0.038, personally out of the 3. Probably even try 0.040 and see if that nets you a tad better centering. But, I realize that's a good amount of work jacking around with all that, it's still worth the extra time now to do it, IMO.