85 442

- Thread starter sldwys

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

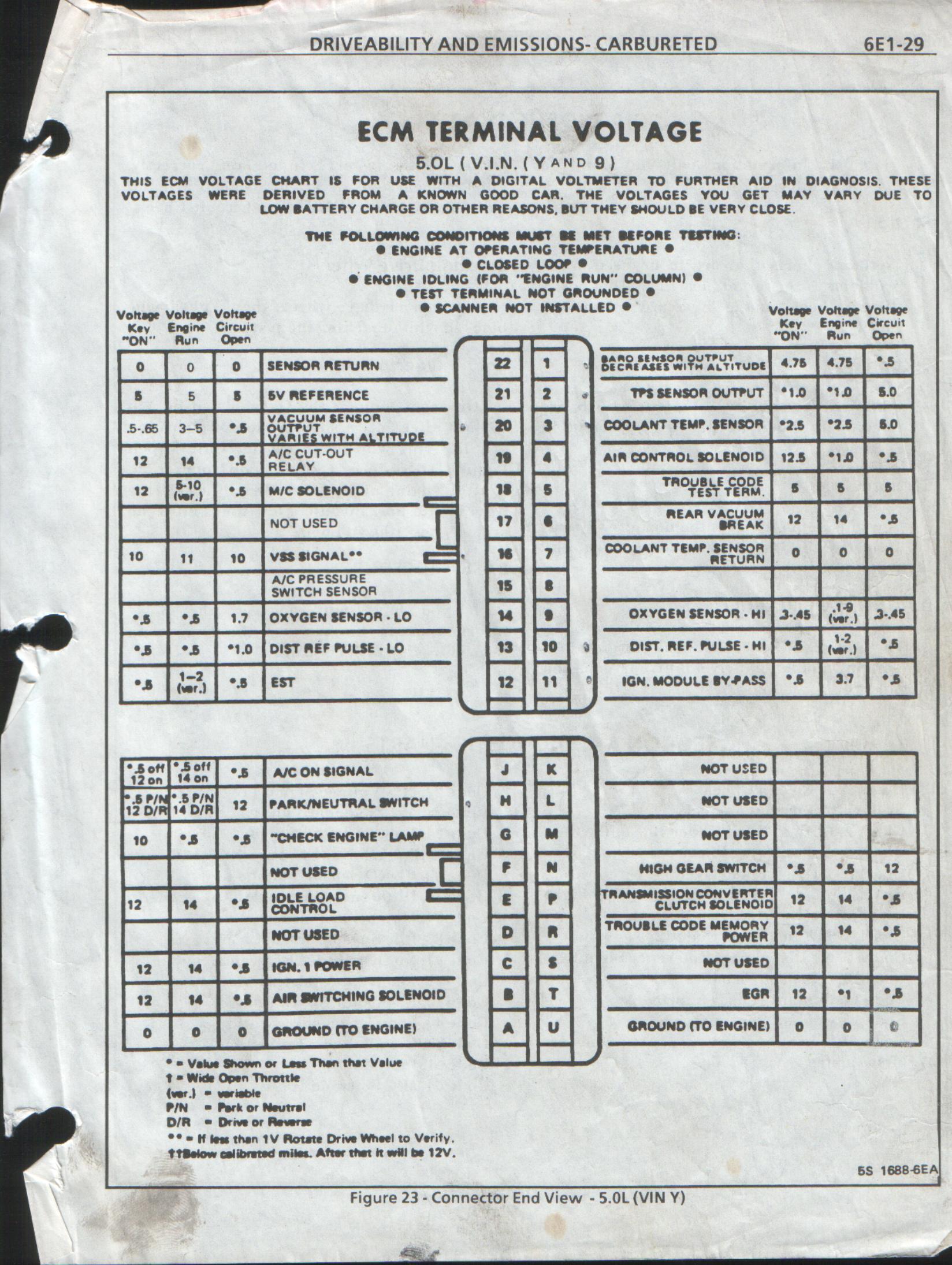

USUALLY the TPS is toast reading high like that. Although you can't rule out a bad ECM (very unlikely but potentially possible) or bad wiring.

I still haven’t drove the car all that much since I’ve had it. So don’t know all it’s demons yet.

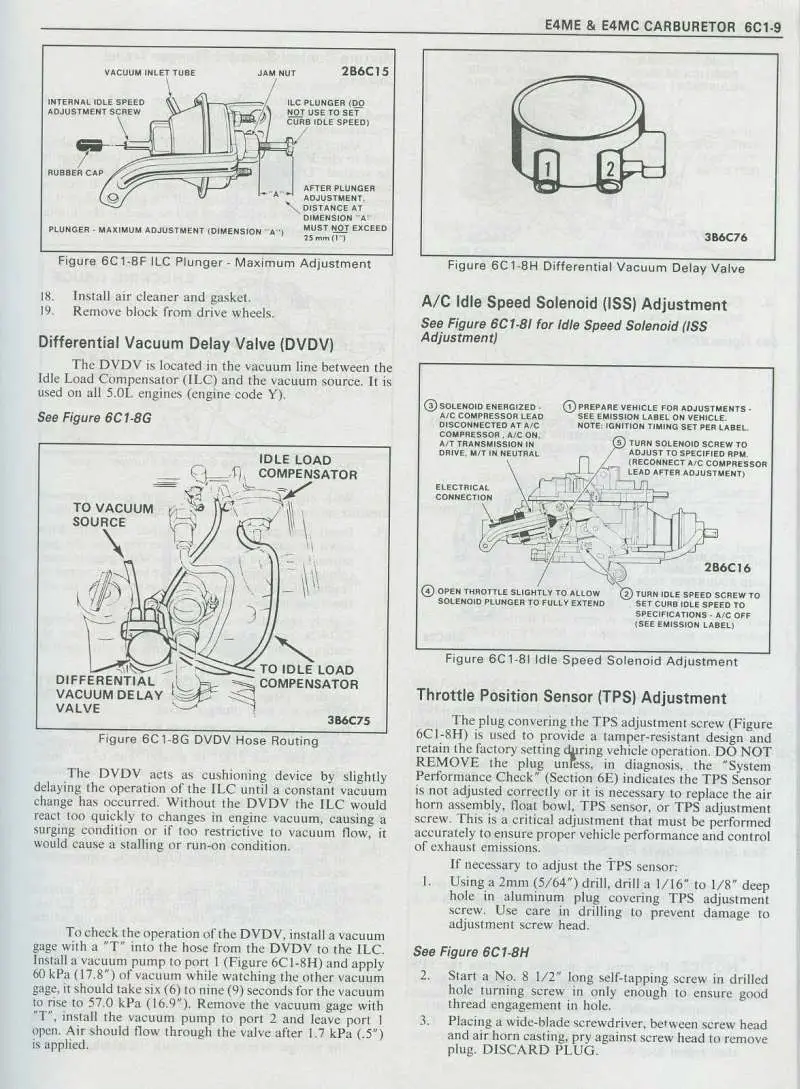

But I have noticed sporadic idling, high, low. So hopefully just TPS sensor.

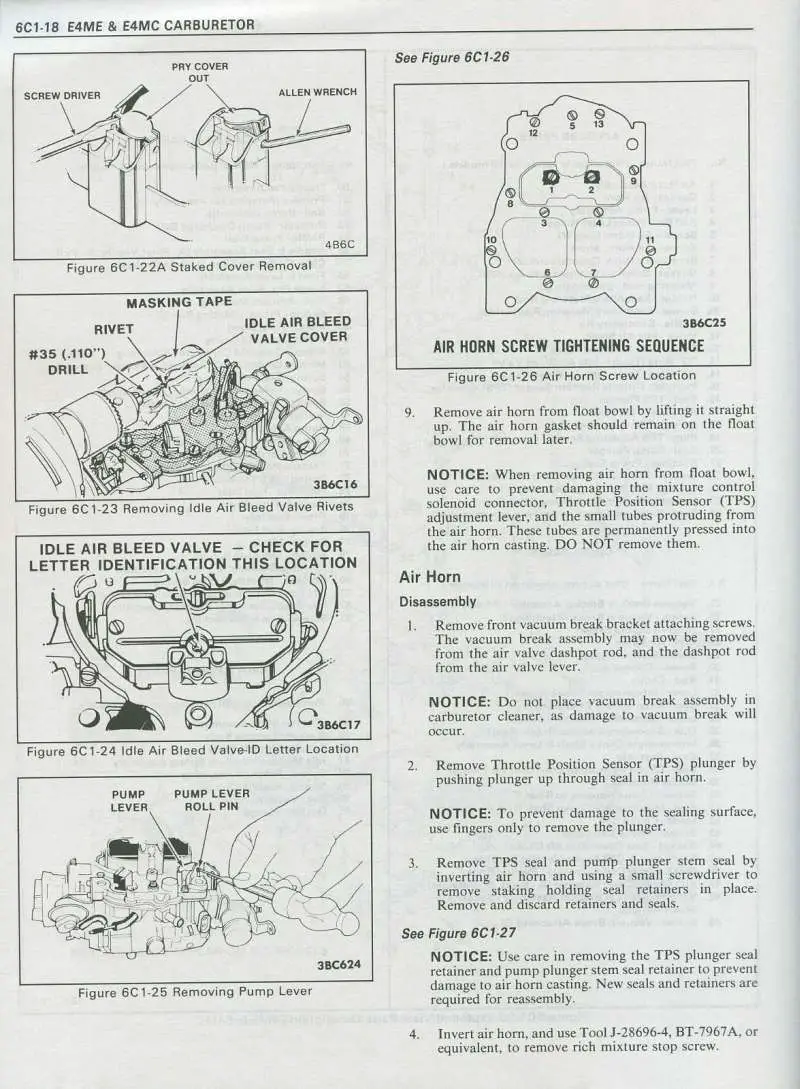

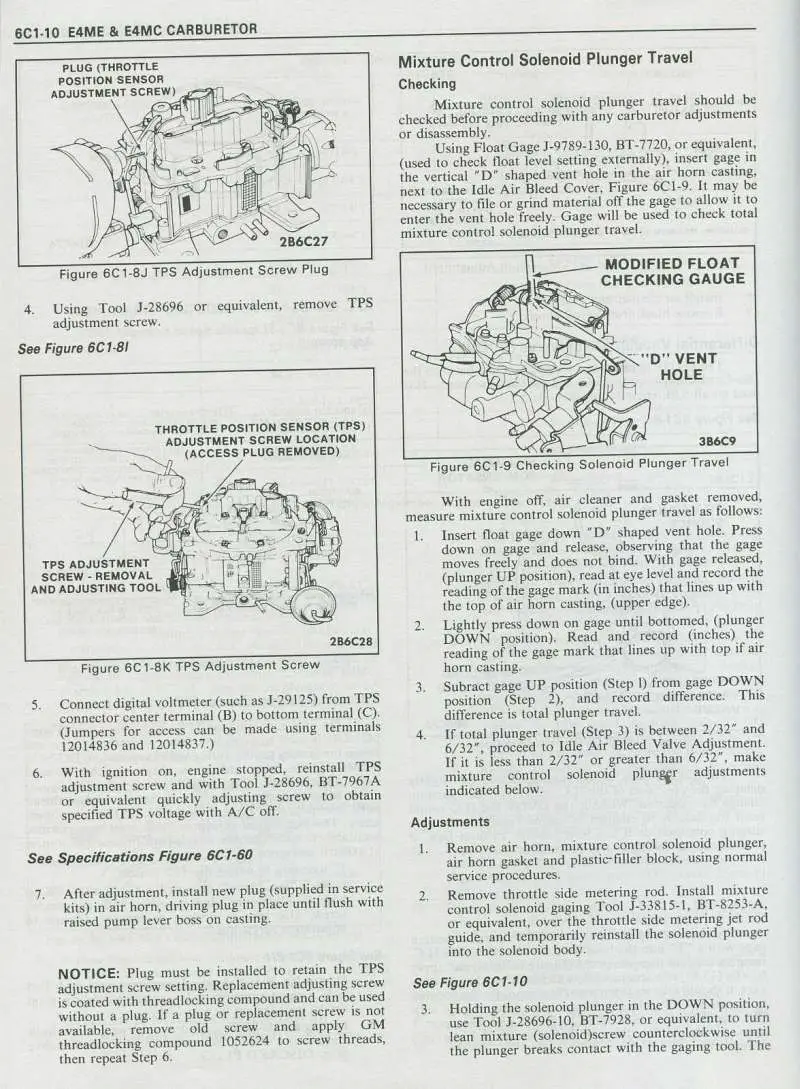

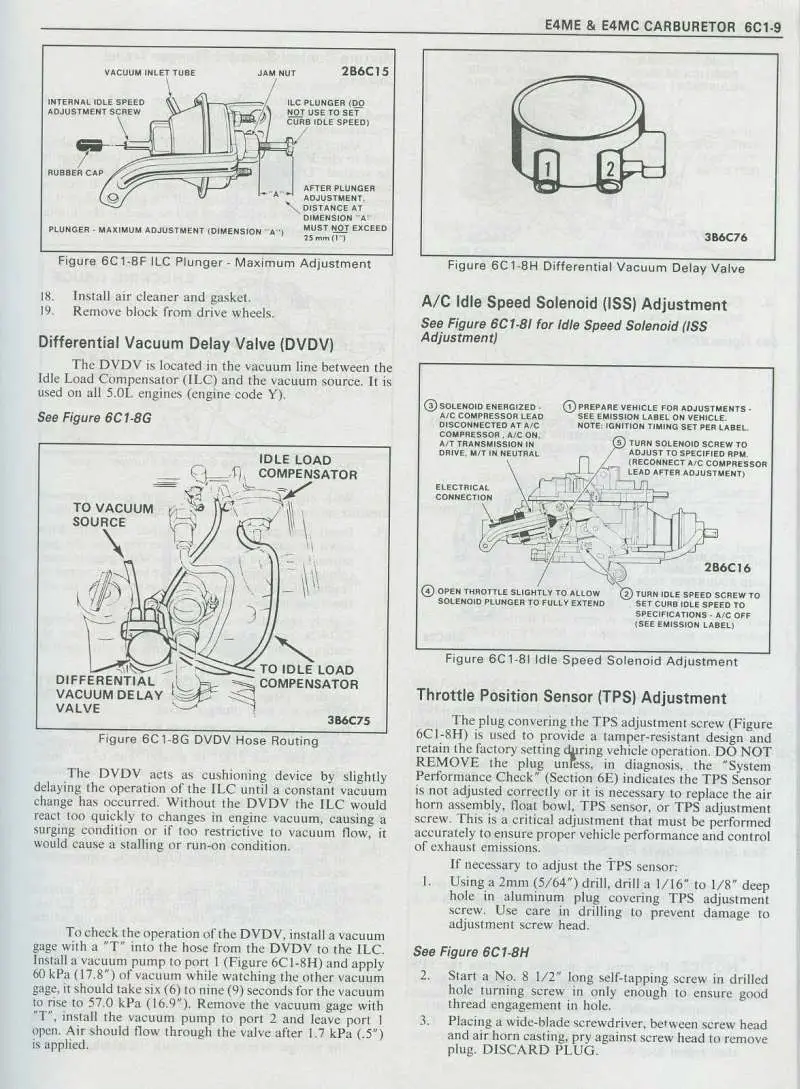

In the video you posted, he didn’t do any drilling? Is this absolutely necessary? Carb work always makes me nervous.

I’ve ordered a tps sensor, and a small rebuild kit from quadrajet power. Just in case I need new air horn gasket.

But I have noticed sporadic idling, high, low. So hopefully just TPS sensor.

In the video you posted, he didn’t do any drilling? Is this absolutely necessary? Carb work always makes me nervous.

I’ve ordered a tps sensor, and a small rebuild kit from quadrajet power. Just in case I need new air horn gasket.

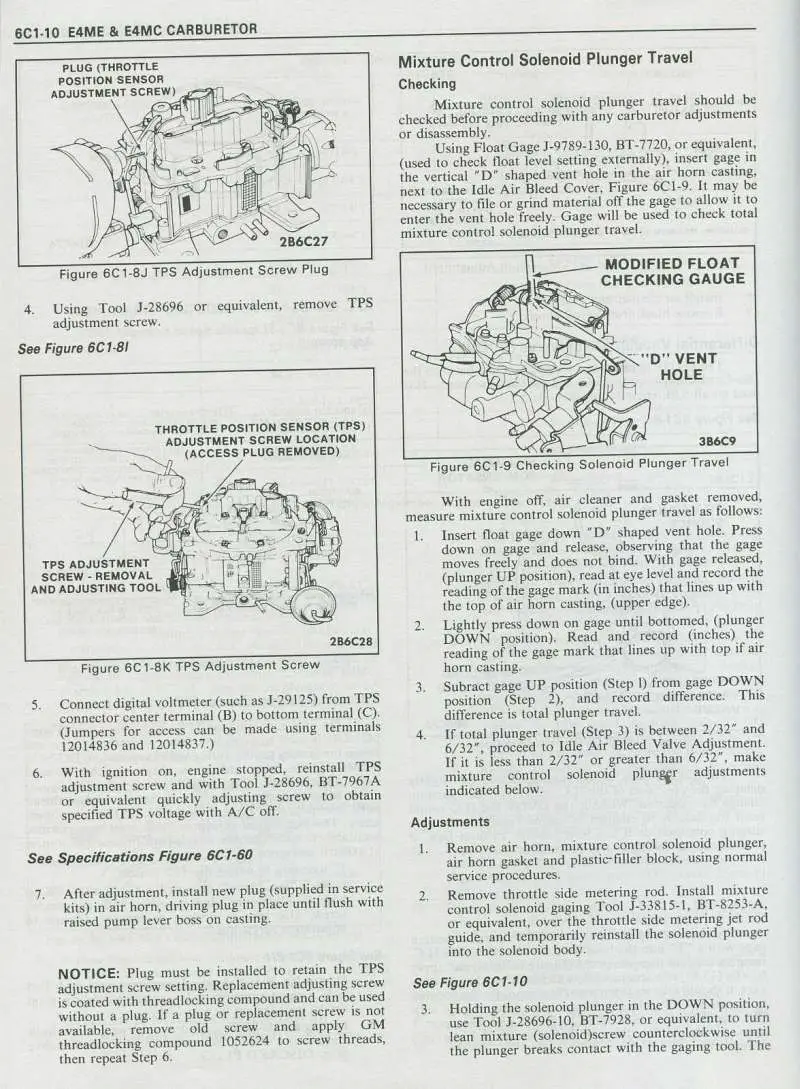

The video of the TPS replacement was just for basic understanding of what needs to be done to replace it if need be. He didn't do it exactly right and never used any instrumentation to ensure he had it adjusted properly. If you don't check it, you'll never know. Ballpark lucky, perhaps. Without the TPS voltage being checked/adjusted properly, the ECM doesn't know if you're at WOT or not. It matters to the CCC stuff.

The TPS cap does 2 things. It's supposed to hold the adjusting screw in place and also keeps out dirt, etc. But if someone had removed it before, and never replaced it, you would have no need to drill out the cap. The book also says you can use thread lock compound GM p/n 1052624, which is the same thing as Permatex High Temperature Sleeve Retainer on the original screw without a cap.

If the adjusting screw was replaced with a service screw, they already were supposed to come with a locking compound on the threads. That's usually not ever.

The TPS cap does 2 things. It's supposed to hold the adjusting screw in place and also keeps out dirt, etc. But if someone had removed it before, and never replaced it, you would have no need to drill out the cap. The book also says you can use thread lock compound GM p/n 1052624, which is the same thing as Permatex High Temperature Sleeve Retainer on the original screw without a cap.

If the adjusting screw was replaced with a service screw, they already were supposed to come with a locking compound on the threads. That's usually not ever.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 168

- Replies

- 2

- Views

- 335

- Replies

- 3

- Views

- 193

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.