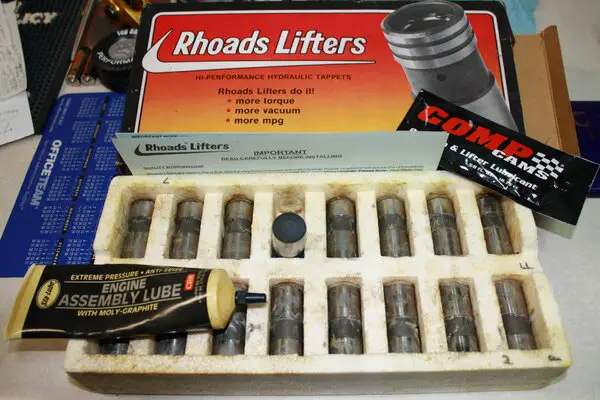

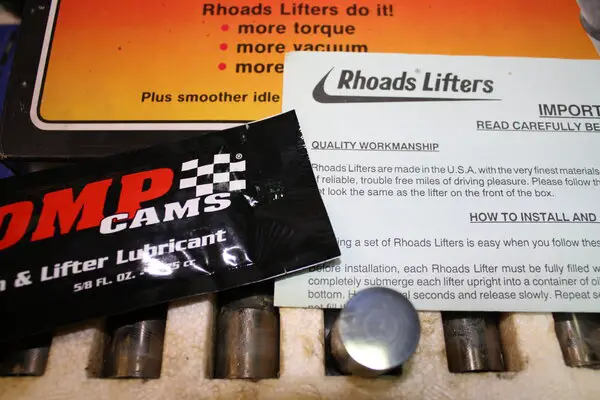

Good Evening 86Monte & all; Jared suggested I mention GM main caps. After tech school (auto engines) I learned at my first engine shop job early 70's, my dream job. From a fantastic boss -owner that sb Chevy main caps usually break into the nearest bolt hole to the crank. Doesn't matter if it has 2 or 4 bolts. So I seen a couple at the shop, but more recently I proved him right again. My #2 406" (1995-2004) made 433 HP w 460 Lb Ft of torque, 27,000 miles over 9 years. It was a perfect engine for my near OE 9C1 chassis? Anyway I have a rule about my Hot Rod (The Bronze Brick) that if I get it out of the garage it will do at least one or two gears at FULL ON! And that set up I had the trans governor set to shift at 6200 RPM. Flat tappet Hyd w/ Roadds variable duration lifters. 10.15 to 1 comp, flat top JE's, 5.7 Eagle rods & AFR heads w/190 cc intake runners & 76 cc chambers. And a very pricey Calies crank. Balanced & clearance++ of course. Well it started making this unusual thumping sound, still made good power. But was time to take it apart. I'll try to post pictures of the two cracked main caps, not one TWO threw the bolt hole of course. The crank was out of round .001", I've come to think that it was holding my engine together! I had it straightened & polished. It's in #3 engine & doing fine. So my advice is keep your power output modest! And pay the price to at least magnaflux the main caps, rods & crank also some APR studs. I solved the problem with a Eagle tool steel Splayed main cap kit. Since I wanted more power I needed more strength! Check all you clearances very carefully so ya don't burn it up. Just in case your interested I still have the lifter w/ directions & they're in very good condition. Any offer + postage & they're yours. Ole' Bob.

Building a SBC 400 Opinions required!

- Thread starter 86montecarlo307

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Excellent information, thank you very much for that. I was unaware of how main caps broke, interesting that they break closer to the crank regardless of 2 or 4 bolt. Good info. I intend on having my trans shift at no higher then 5500. Hoping that will help a little with the strain on the lower end a bit. Being that i have limited funds i am going to sti k with a hydraulic flat tappet cam for this one. Its my first engine im building, i expect to learn some lessons from this haha. I plan on being very very careful with clearences and all other tolerances. Im only hoping to make 350 horsepower, more would be great, but i dont want to cause reliability issues. Then again, alot of that depends on how youre going to drive it too xDGood Evening 86Monte & all; Jared suggested I mention GM main caps. After tech school (auto engines) I learned at my first engine shop job early 70's, my dream job. From a fantastic boss -owner that sb Chevy main caps usually break into the nearest bolt hole to the crank. Doesn't matter if it has 2 or 4 bolts. So I seen a couple at the shop, but more recently I proved him right again. My #2 406" (1995-2004) made 433 HP w 460 Lb Ft of torque, 27,000 miles over 9 years. It was a perfect engine for my near OE 9C1 chassis? Anyway I have a rule about my Hot Rod (The Bronze Brick) that if I get it out of the garage it will do at least one or two gears at FULL ON! And that set up I had the trans governor set to shift at 6200 RPM. Flat tappet Hyd w/ Roadds variable duration lifters. 10.15 to 1 comp, flat top JE's, 5.7 Eagle rods & AFR heads w/190 cc intake runners & 76 cc chambers. And a very pricey Calies crank. Balanced & clearance++ of course. Well it started making this unusual thumping sound, still made good power. But was time to take it apart. I'll try to post pictures of the two cracked main caps, not one TWO threw the bolt hole of course. The crank was out of round .001", I've come to think that it was holding my engine together! I had it straightened & polished. It's in #3 engine & doing fine. So my advice is keep your power output modest! And pay the price to at least magnaflux the main caps, rods & crank also some APR studs. I solved the problem with a Eagle tool steel Splayed main cap kit. Since I wanted more power I needed more strength! Check all you clearances very carefully so ya don't burn it up. Just in case your interested I still have the lifter w/ directions & they're in very good condition. Any offer + postage & they're yours. Ole' Bob.

With what you want to accomplish a head with a 170 - 180 runner would be great. Seeing your on a limited budget a set of vortex heads would be great. My car has stock iron 2.02 heads w/ runners in the 180's and I'm north of 450 HP. With a 220 runner you would hurt your bottom end and they wouldn't start breathing till 5500 - 6000.

I'd keep over bore down to.030 for one. Your could also build a 377 high winding engine where those 220 runners would be useful. That's a different animal.

I am running a 406 in my car currently. It his a hydraulic flat tappet as well, cam profile sounds similar. I have trick flow twisted wedge heads on it, i believe theyare 195cc runners. Makes lenty of power and torque. 220's would be too large though as everyone else here has mentioned. As for block strength my dad has a two bolt 406 with a big solid roller setup probably pushing 575-600hp. It has been beat for over 4 years now and is still going stong. No splayed mains, just ARP studs. I guess it all depends on your luck and the block, but we have had good luck with our 400s'.

I havent bought the heads yet, or the cam, this was just my build idea, as people comment ive been changine things. That being said its already bored 40 over, was that way when i got it -.-I'd keep over bore down to.030 for one. Your could also build a 377 high winding engine where those 220 runners would be useful. That's a different animal.

sounds interesting, i found a set of 190cc runner heads i will probably go with instead lf the 220 since everyone says theyre too big. I was considering vortec heads, but ive already got my intake bought, and valve covers.. and id need to buy new of both to run the vortec heads.I am running a 406 in my car currently. It his a hydraulic flat tappet as well, cam profile sounds similar. I have trick flow twisted wedge heads on it, i believe theyare 195cc runners. Makes lenty of power and torque. 220's would be too large though as everyone else here has mentioned. As for block strength my dad has a two bolt 406 with a big solid roller setup probably pushing 575-600hp. It has been beat for over 4 years now and is still going stong. No splayed mains, just ARP studs. I guess it all depends on your luck and the block, but we have had good luck with our 400s'.

Greetings 86Monte & all; I would lean ya to the 190's, that's what I used on #2. They can in most cases be ported larger with more modern programs in the future. I've seen & heard this more than should, new heads these days are coming with very poor guides. Consider dissemble checking (guides, seats & spring compatibly) cleaning & re assembly with some ZDDP-MOLY paste (its usually black) on the valve stems. By the way the #2 build of mine the one that actually sat on a dyno making 433 HP with the AFR 190 heads we just mentioned had a 224*I-228*E duration @.050" & buzzed easily to 6100-6200 RPM. It had a custom 650 Holley that flowed about 680-690 CFM. Not the carb you see in the pictures. My first #1 406 that we didn't speak of much had a 222* @ .050" both with Roadds lifters. Also the heads on #1 were very ported 1974 OE 400's (maybe 175 cc runners?). It liked 5700-5800 & didn't require heavy valve springs (think longevity). And don't forget VR1 oil after brake in. EOS or break-in oil for the first 300-500 miles. I've also been informed cam grinders would like to see two changes of break-in oil & that even includes roller cammed engines witch can be more susceptible to small partial damage. One hour or 100 miles & dump, second round break-in 500-700 miles. I know it's an expensive process but it works! Good Luck Ole' Bob.

Ps: I'll post the pictures of the Roadd's lifters & I've got a tube of that black paste that I mentioned.

Ps: I'll post the pictures of the Roadd's lifters & I've got a tube of that black paste that I mentioned.

Attachments

I will be going through the heads i buy, and will probably be buying whatever springs lunati wants me to run with the cam i buy. I am huge on proper break in, when i first installed my ford 9" in my monte they asked for 5 short 15 min runs with very gentle driving as break in, i probably doubled that honestly, and have changed the oil twice. Ill be extra thorough on the engine aswell. Last thing i want is premature failure due to break in/user error. As for lifters, ill be buying a matching set from lunati with lifters and a cam, so i should be good on them for now. Thanks a ton though. Ill keep that paste in mind though!Greetings 86Monte & all; I would lean ya to the 190's, that's what I used on #2. They can in most cases be ported larger with more modern programs in the future. I've seen & heard this more than should, new heads these days are coming with very poor guides. Consider dissemble checking (guides, seats & spring compatibly) cleaning & re assembly with some ZDDP-MOLY paste (its usually black) on the valve stems. By the way the #2 build of mine the one that actually sat on a dyno making 433 HP with the AFR 190 heads we just mentioned had a 224*I-228*E duration @.050" & buzzed easily to 6100-6200 RPM. It had a custom 650 Holley that flowed about 680-690 CFM. Not the carb you see in the pictures. My first #1 406 that we didn't speak of much had a 222* @ .050" both with Roadds lifters. Also the heads on #1 were very ported 1974 OE 400's (maybe 175 cc runners?). It liked 5700-5800 & didn't require heavy valve springs (think longevity). And don't forget VR1 oil after brake in. EOS or break-in oil for the first 300-500 miles. I've also been informed cam grinders would like to see two changes of break-in oil & that even includes roller cammed engines witch can be more susceptible to small partial damage. One hour or 100 miles & dump, second round break-in 500-700 miles. I know it's an expensive process but it works! Good Luck Ole' Bob.

Ps: I'll post the pictures of the Roadd's lifters & I've got a tube of that black paste that I mentioned.

If the rings are undamaged and the end gaps are within spec, just re-use them without honing the bore. That's what Speed-Pro and most other say to do, and they're the ones who sell them.

If the bore is scratched or damaged or the rings have to be replaced, have the shop run a dingleberry hone of the correct grit through to texture the surface.

Power honing a used 400 block is a bad idea. GM cut every corner they could back then, and the iron they used was very soft so they could economize on tooling costs. 400s usually have wear on the thrust side and near top dead center; if you try to hone all that out, you'll wind up with a grossly oversized bore with noise and poor ring life.

If the bore is scratched or damaged or the rings have to be replaced, have the shop run a dingleberry hone of the correct grit through to texture the surface.

Power honing a used 400 block is a bad idea. GM cut every corner they could back then, and the iron they used was very soft so they could economize on tooling costs. 400s usually have wear on the thrust side and near top dead center; if you try to hone all that out, you'll wind up with a grossly oversized bore with noise and poor ring life.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 228

- Replies

- 3

- Views

- 147

- Replies

- 0

- Views

- 84

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.