After following along the shifter bushing & Parts Place linkage kit threads I started to look at my OE clutch linkage parts & the Hurst shifter to see how everything is in good functional condition. Shifter is unused with the plastic bushing but I'm thinking about changing them over to metal. Then with both sets of clutch linkage the rod holes are worn/out of round. Now this will cause some issues trying to get a good adjustment so I'm coming up with an idea to extend the life of the parts & save a few bucks on not buying new parts. The idea is to bore the holes out just enough to get them round to put in a bushing to regain the correct hole size. I would like to make the bushings replaceable when the holes wear enough to affect the adjustment. I'm now trying to figure out if I should use steel or oilite bronze for the bushings. Which would have the best wear life as a piviot point that will have to deal the pressure when pushing the clutch in. The size of the bushing should be 5/16" i.d. x 3/8" o.d. x 1/4" long with possible changes to the o.d. to 7/16" or 1/2" if the egg shape can't be corrected at 3/8". One down side I can see at this time is not being able to put the car on the road to see how it'll feel & function since everything is still apart. So any comments or suggestions to make this theory into a fuctioning fix for worn linkage holes would be great.

Clutch linkage bushing project, trying to redo OE parts

- Thread starter pagrunt

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

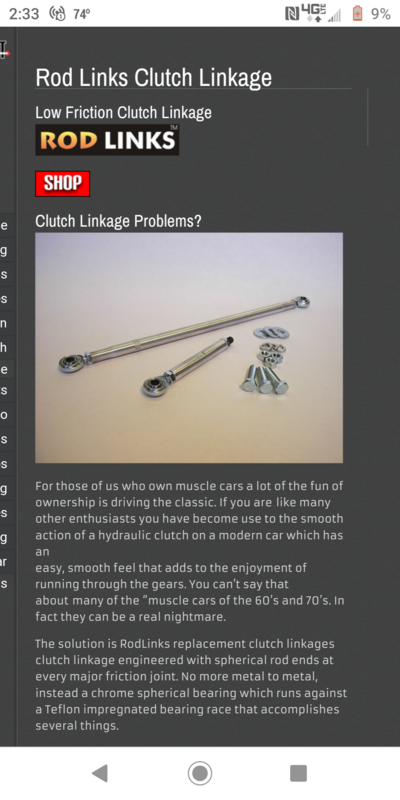

I gave up and got the speed direct linkage with heim joints. Made such a huge improvement and eliminated 3 wear points.

The basic design is poor, because it was just a plain, mass produced car. Do what gnvair said IMO

You can also do like I did in this thread;

gbodyforum.com

Guy

gbodyforum.com

Guy

Worn Clutch Z Bar

The old Doug Nash 4+1 started getting hard to shift last year and at first I thought it was the clutch. I thought about it all winter and realised that I didnt want to pull the transmission until I checked into it further. So I looked at excess play in the clutch linkage to start.The holes in...

gbodyforum.com

gbodyforum.com

Bronze will be smoother and wear out (eventually). Steel will last longer but feel "racier". You can get new gates for the shifter and shift levers to get new holes. Rebuilding the shifter mechanism isn't hard.

I've thought about that (& forgot about the other thread about worn linkage with that suggestion) with modifing the old upper rod to accept heim joints with the lower swivel replaced with a heim. But part of the idea is to make the bushings sacrificial so as they wear out I can punch them out for new ones & still hold a "factory stock" appearance. Even going with heim joints I'll need to fix the holes. I did try to look at Speed Direct's site but my computers security won't allow my to open the page with our linkage cause their site's security is out of date.I gave up and got the speed direct linkage with heim joints. Made such a huge improvement and eliminated 3 wear points.

The bronze bushing would be for the clutch linkage, the shifter is a new Hurst (China madeBronze will be smoother and wear out (eventually). Steel will last longer but feel "racier". You can get new gates for the shifter and shift levers to get new holes. Rebuilding the shifter mechanism isn't hard.

) with the included plastic bushings cause I couldn't find my left over stash of steel bushing in with my shifter from my '72 Monte (loved the feel of the shift with them in that land barge.) I'm most likely will be ordering a set & readjust the rods again to make it feel better than it does now (can't resist running thru the gears while think things over in the garage.)

) with the included plastic bushings cause I couldn't find my left over stash of steel bushing in with my shifter from my '72 Monte (loved the feel of the shift with them in that land barge.) I'm most likely will be ordering a set & readjust the rods again to make it feel better than it does now (can't resist running thru the gears while think things over in the garage.)https://www.amazon.com/dp/B000BWALCO/?tag=gbody-20

I also put some thin 3/8" grade 8 washers on the clip side to reduce friction and slop.

I also put some thin 3/8" grade 8 washers on the clip side to reduce friction and slop.

Understood.I've thought about that (& forgot about the other thread about worn linkage with that suggestion) with modifing the old upper rod to accept heim joints with the lower swivel replaced with a heim. But part of the idea is to make the bushings sacrificial so as they wear out I can punch them out for new ones & still hold a "factory stock" appearance. Even going with heim joints I'll need to fix the holes. I did try to look at Speed Direct's site but my computers security won't allow my to open the page with our linkage cause their site's security is out of date.

The bronze bushing would be for the clutch linkage, the shifter is a new Hurst (China made) with the included plastic bushings cause I couldn't find my left over stash of steel bushing in with my shifter from my '72 Monte (loved the feel of the shift with them in that land barge.) I'm most likely will be ordering a set & readjust the rods again to make it feel better than it does now (can't resist running thru the gears while think things over in the garage.)

https://www.amazon.com/dp/B000BWALCO/?tag=gbody-20

I also put some thin 3/8" grade 8 washers on the clip side to reduce friction and slop.

I do this too.

The more play you can take out,the better !!

Guy

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 262

- Replies

- 6

- Views

- 538

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.