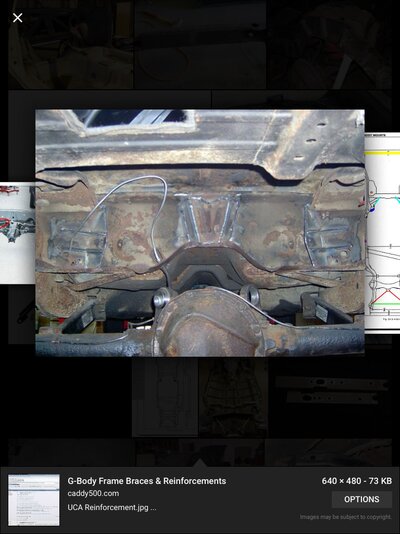

I've been running Nitto drag radials at the track and approaching sub 13 second quarter mile times with the Olds. Future plans will likely put the car in the 11's so I'm a little worried about the rear control arm mounts. I've done some reading but I'm still a little confused as to whether the uppers, lowers or both control arm mounting locations are weak on a G body.

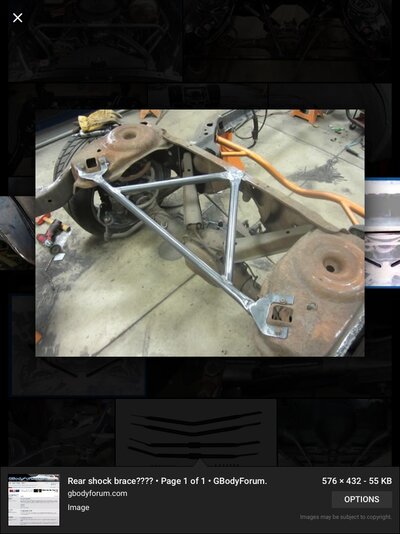

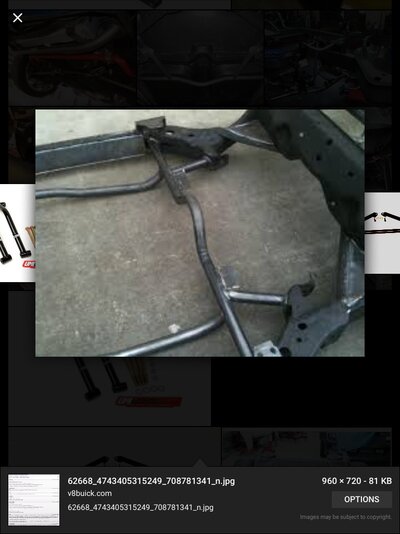

Has anyone on this forum damaged their chassis from launching too hard? If so, was it the lowers or uppers? I'm considering the Hotchkis or UMI reinforcement bars but don't understand the physics and how these design's address the issue. I would rather not add the weight if welding in gussets would be enough. Here's a link to the UMI bars.....Opinions anyone? Make me a believer.

http://umiperformance.com/catalog/index ... cts_id=350

Has anyone on this forum damaged their chassis from launching too hard? If so, was it the lowers or uppers? I'm considering the Hotchkis or UMI reinforcement bars but don't understand the physics and how these design's address the issue. I would rather not add the weight if welding in gussets would be enough. Here's a link to the UMI bars.....Opinions anyone? Make me a believer.

http://umiperformance.com/catalog/index ... cts_id=350