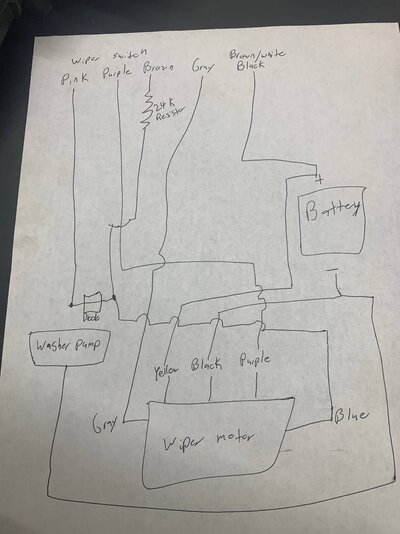

So I might have figured out a way to get delay wipers in a gbody, or have a work around for the cover that’s made of unobtainium for the factory delay. I started with the work that Wageslave did using a Pontiac Bonneville wiper motor that he never got it working correctly. Well I took a wiper motor off of the inlaws junk 04 bonneville and started doing some testing, and I got the same results as he did. I tried several different things before coming up with one that worked. I ordered a wiper switch for an 86 c10 with delay wipers(should work for 85-91 squarebodies even thought 88-91 show different part numbers). Then I tested which wires I would need, found that only one set of wires would vary resistance and of course they didn’t have power, so I put the one side to 12 volt. Oh and I had to completely repin the connector because they are all different too… Black wire on the wiper switch is 12 volt, and I used brown/white for 12 volt too to vary the resistance. Then I used gray switch to gray harness, brown switch to green harness, purple to purple, and pink to pink. Then on the motor end it was purple to purple, pink goes to washer motor, green harness to blue motor. Now you need a 24k ohm resistor on the brown or blue wire depending on which end that you put it, and a diode between the blue or brown(once again depending on which end you put it) and the pink wire so the wiper motor will run in the mist or wash position and not run the washer pump with the motor running. I’m going to put the washer pump on a relay so I don’t have to worry about the diode being heavy enough to carry the load. Only thing I can really see that doesn’t work 100% is sometimes when you go straight from low or high to off the wipers cycle a couple of times yet. In delay they cycle from about 1 second, to about 20 seconds, where my 04 silverado does from about 1 second to 12 seconds, most likely because the resistance isn’t quite the same as a Bonneville switch. I picked up a chevy venture wiper motor to try to get the hidden park, but while it “worked” with the Bonneville switch when I first tried it, it decided it wasn’t even going to work correctly with that today, so most likely I shorted something out in the module. I’m a long ways from getting it in my El Camino, but maybe it might help someone else get it in. I don’t think its that bad to change the wiper switch in the column. Here is a link to the posts that has some other information about actually mounting the motor and what got me going with it. https://gbodyforum.com/threads/delay-wipers.76905/page-4

Now the worst part of this whole thing, is my delay works perfect as of right now with the original cover.…

Link to a video that I made.

Now the worst part of this whole thing, is my delay works perfect as of right now with the original cover.…

Link to a video that I made.