Hello folks,

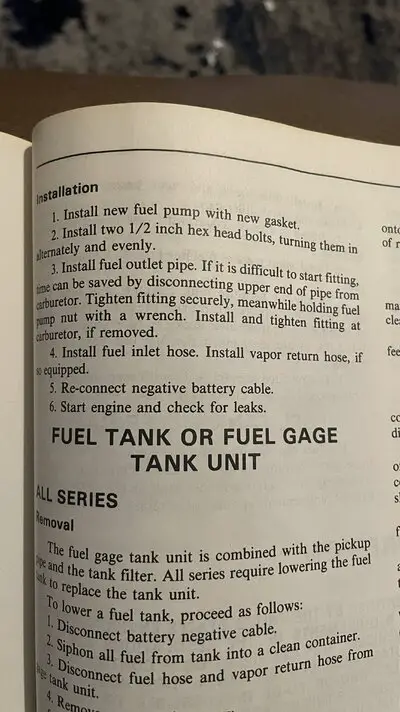

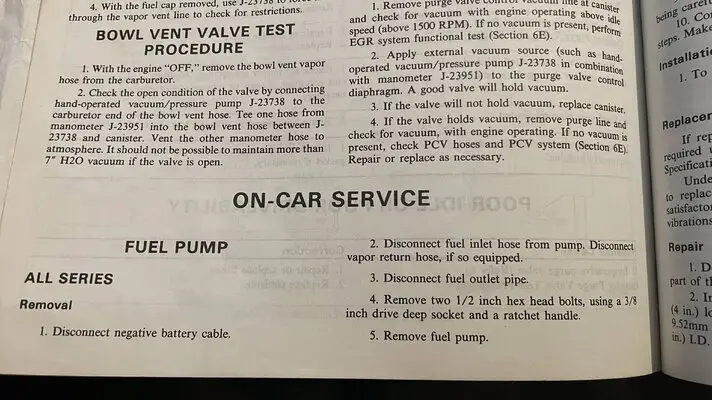

Looking for advice on how to go about removing the pump from an 81/265 GP.

Long story short: fuel line to carb had a hole, factory one was on so tight pump bent a bit and created a small hole when removing the line.

Now pump is squirting, i've tried with a wrench to loosen up the screws it's a tight spot.

Any tips/tricks?

Was hard to get a good video:

thanks

Looking for advice on how to go about removing the pump from an 81/265 GP.

Long story short: fuel line to carb had a hole, factory one was on so tight pump bent a bit and created a small hole when removing the line.

Now pump is squirting, i've tried with a wrench to loosen up the screws it's a tight spot.

Any tips/tricks?

Was hard to get a good video:

thanks