Hey guys

As some of you may know if you follow my build thread, I've been working on my header panel lately and it's come time to turn my attention to the grilles on the car.

Upon starting to restore and detail my grilles, I came upon a couple issues with them that I believe are probably common to most G bodies, not just Cutlasses. So I thought I'd post up how I repaired them in case it helps others out. With the exception of two specialty products, these repairs can likely be made with common materials you probably already have in your garage.

Here's what I found that needed repairing:

A crack in the bottom flange of one grille:

An overtightened screw that split the mount:

And a single fin on the front side that somehow got smeared:

First thing you need to do is determine the type of material you're working with. In my case, the grilles are ABS plastic (they're usually stamped on the back somewhere). I located the appropriate solvent necessary to repair ABS locally from a paint and plastic specialty store, you'll need to source it from wherever works for you.

For the first two repairs, this is what was used.

It's called methylene chloride, and it's used for welding ABS plastics together. I got this bottle and the applicator for less than $10.

To repair the crack, the grille was placed in a vice to hold it steady, and a small amount was flowed into the crack. This stuff is a solvent and evaporates pretty fast, so you'll need to work quickly. Light steady pressure was applied either side of the crack until I was sure the plastic was fused, then it was set aside for approx a half hour.

Word of advise: resist the temptation to tug on it to see if the plastic fused, especially in the first few mins. It takes a bit for it to do its job, just set it aside and go work on something else. (Ask me how I know)

After a half hour, the repair was fully cured, and just as strong as before the break.

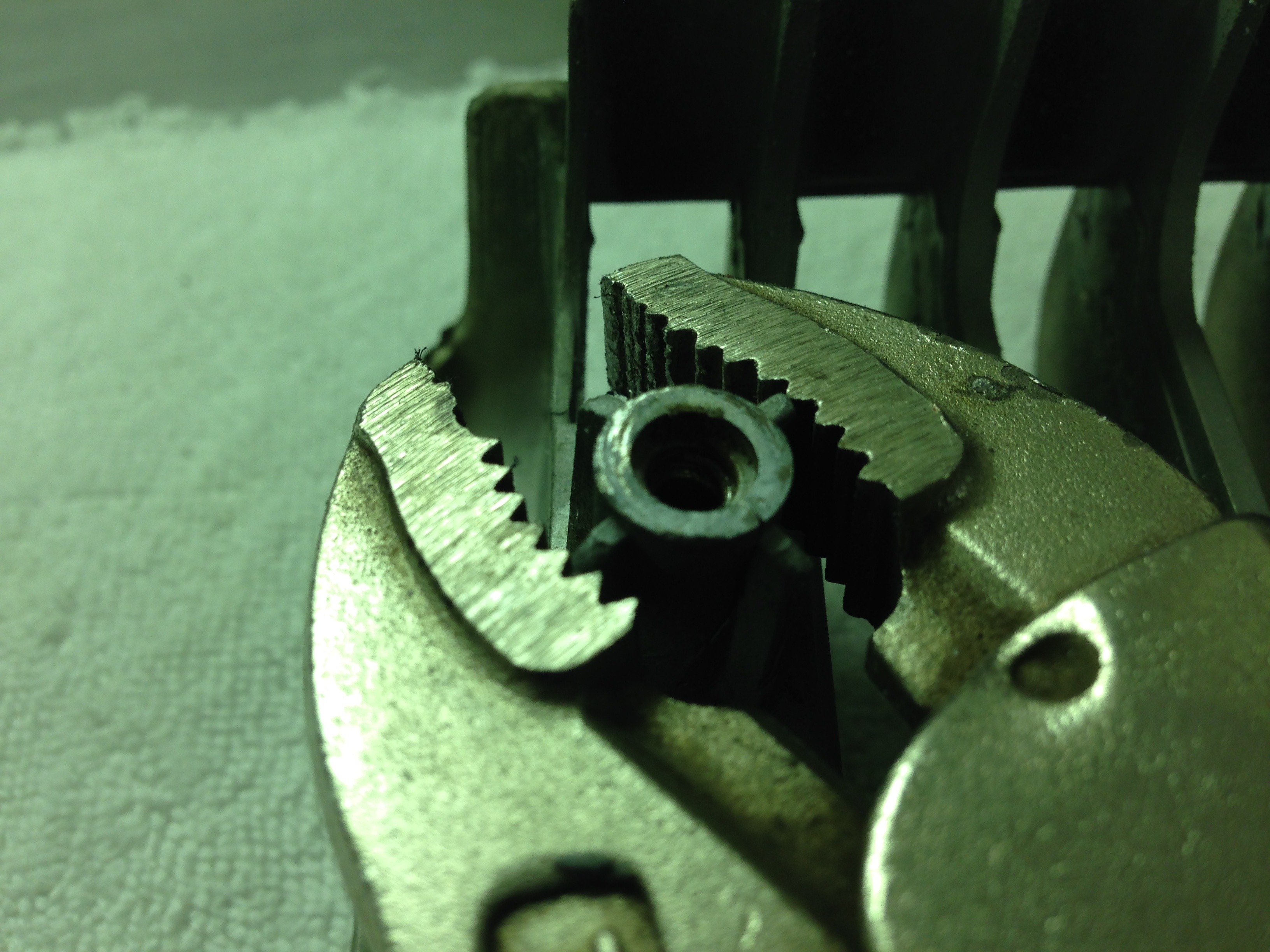

To repair the damaged mount, a small pair of vice grips were carefully clamped around the mount with just enough tension to SLIGHTLY close up the cracks.

Don't try and fully close the gaps, you could risk breaking it completely!

With that done, the entire mount and the cracked area in particular was flooded with more solvent than necessary. This happened by accident, but as I found out, it was actually a good thing because the excess solvent softens up the surrounding plastic, allowing the gap to close up with the tension from the vice grips. Again, set it aside and go do something else. Patience is a virtue here. When you're sure the repair has cured, you can release the vice grips and inspect your repair.

This is what mine looked like after the repair.

The cracks are still visible, but the large gaps that were there have closed up entirely, and it's holding solid!

And lastly, to repair the smeared fin on the front, I sanded down the sides of the damaged area to remove the displaced plastic, then roughed up the center with some 120 grit sandpaper. Clean and wipe the entire area down thoroughly with a good wax and grease remover, then get ready to apply the repair compound.

I used 3M's semi-rigid parts repair #08235. It is compatible with many different plastics including ABS.

I laid down a small bead of this stuff on top of the fin, then let it cure overnight.

Again, this stuff too sets up fast, so be prepared ahead of time. 3M claims only 50 seconds work time, 30 minutes to sand time, and fully cured in 1 hour.

After the bead had cured, I took a small thin block and sanded it near flush with 120 grit paper, then followed that up with 220 and 320 till it was perfectly flat. Clean and wipe down the area again, next step is primer.

I masked off everything but the damaged fin, then hit it with etch primer, followed by 3 coats of regular primer surfacer. No need for fancy expensive products here, spraybombs will work fine.

Once the primer was dry, I VERY lightly sanded the primer smooth with 400 grit paper. Clean and wipe down the area again, more masking, this time for paint. I picked up some DupliColor "Chrome" spray paint. This stuff doesn't really look like chrome, rather it's more like a really shiny silver, but it should closely match your grille, especially if it's already slightly faded.

When you go to paint, don't try and paint the entire piece. All you want to do is have paint on the repaired area only, try and blend off the edges into the original chrome.

When I was done, I tried to take this closeup photo, and had trouble telling which fin was the repaired one on the screen.

Lol

I had to put a piece of masking tape with an arrow on it to show which one was repaired (it's the one in front of the arrow, the 7th one from the left).

Here's the repaired grille viewed from the front, can you see the repaired fin?

You will likely have to tailor your repairs to your specific damage and application, but hopefully you'll be able to use some of the repair methods and products I've outlined here.

Good luck and thanks for reading.

Donovan

As some of you may know if you follow my build thread, I've been working on my header panel lately and it's come time to turn my attention to the grilles on the car.

Upon starting to restore and detail my grilles, I came upon a couple issues with them that I believe are probably common to most G bodies, not just Cutlasses. So I thought I'd post up how I repaired them in case it helps others out. With the exception of two specialty products, these repairs can likely be made with common materials you probably already have in your garage.

Here's what I found that needed repairing:

A crack in the bottom flange of one grille:

An overtightened screw that split the mount:

And a single fin on the front side that somehow got smeared:

First thing you need to do is determine the type of material you're working with. In my case, the grilles are ABS plastic (they're usually stamped on the back somewhere). I located the appropriate solvent necessary to repair ABS locally from a paint and plastic specialty store, you'll need to source it from wherever works for you.

For the first two repairs, this is what was used.

It's called methylene chloride, and it's used for welding ABS plastics together. I got this bottle and the applicator for less than $10.

To repair the crack, the grille was placed in a vice to hold it steady, and a small amount was flowed into the crack. This stuff is a solvent and evaporates pretty fast, so you'll need to work quickly. Light steady pressure was applied either side of the crack until I was sure the plastic was fused, then it was set aside for approx a half hour.

Word of advise: resist the temptation to tug on it to see if the plastic fused, especially in the first few mins. It takes a bit for it to do its job, just set it aside and go work on something else. (Ask me how I know)

After a half hour, the repair was fully cured, and just as strong as before the break.

To repair the damaged mount, a small pair of vice grips were carefully clamped around the mount with just enough tension to SLIGHTLY close up the cracks.

Don't try and fully close the gaps, you could risk breaking it completely!

With that done, the entire mount and the cracked area in particular was flooded with more solvent than necessary. This happened by accident, but as I found out, it was actually a good thing because the excess solvent softens up the surrounding plastic, allowing the gap to close up with the tension from the vice grips. Again, set it aside and go do something else. Patience is a virtue here. When you're sure the repair has cured, you can release the vice grips and inspect your repair.

This is what mine looked like after the repair.

The cracks are still visible, but the large gaps that were there have closed up entirely, and it's holding solid!

And lastly, to repair the smeared fin on the front, I sanded down the sides of the damaged area to remove the displaced plastic, then roughed up the center with some 120 grit sandpaper. Clean and wipe the entire area down thoroughly with a good wax and grease remover, then get ready to apply the repair compound.

I used 3M's semi-rigid parts repair #08235. It is compatible with many different plastics including ABS.

I laid down a small bead of this stuff on top of the fin, then let it cure overnight.

Again, this stuff too sets up fast, so be prepared ahead of time. 3M claims only 50 seconds work time, 30 minutes to sand time, and fully cured in 1 hour.

After the bead had cured, I took a small thin block and sanded it near flush with 120 grit paper, then followed that up with 220 and 320 till it was perfectly flat. Clean and wipe down the area again, next step is primer.

I masked off everything but the damaged fin, then hit it with etch primer, followed by 3 coats of regular primer surfacer. No need for fancy expensive products here, spraybombs will work fine.

Once the primer was dry, I VERY lightly sanded the primer smooth with 400 grit paper. Clean and wipe down the area again, more masking, this time for paint. I picked up some DupliColor "Chrome" spray paint. This stuff doesn't really look like chrome, rather it's more like a really shiny silver, but it should closely match your grille, especially if it's already slightly faded.

When you go to paint, don't try and paint the entire piece. All you want to do is have paint on the repaired area only, try and blend off the edges into the original chrome.

When I was done, I tried to take this closeup photo, and had trouble telling which fin was the repaired one on the screen.

Lol

I had to put a piece of masking tape with an arrow on it to show which one was repaired (it's the one in front of the arrow, the 7th one from the left).

Here's the repaired grille viewed from the front, can you see the repaired fin?

You will likely have to tailor your repairs to your specific damage and application, but hopefully you'll be able to use some of the repair methods and products I've outlined here.

Good luck and thanks for reading.

Donovan