Olds 358 build

- Thread starter olds307 and 403

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

You sure did😁. Pretty warm in my garage. I probably should wear actually shoes or my work boots when I install the 330 crank tonight💡.NICE !

Did I spot Safety Sandals ?

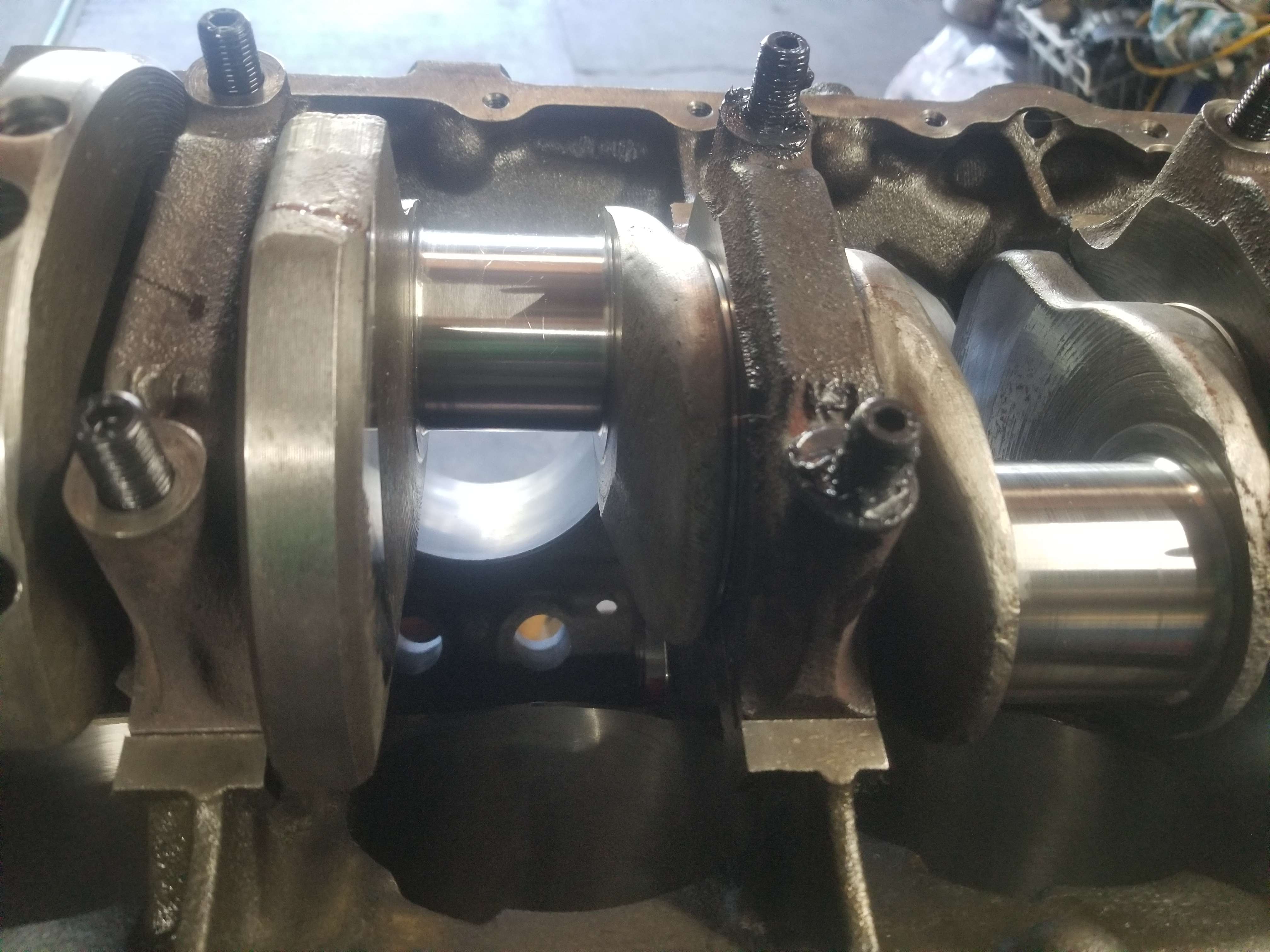

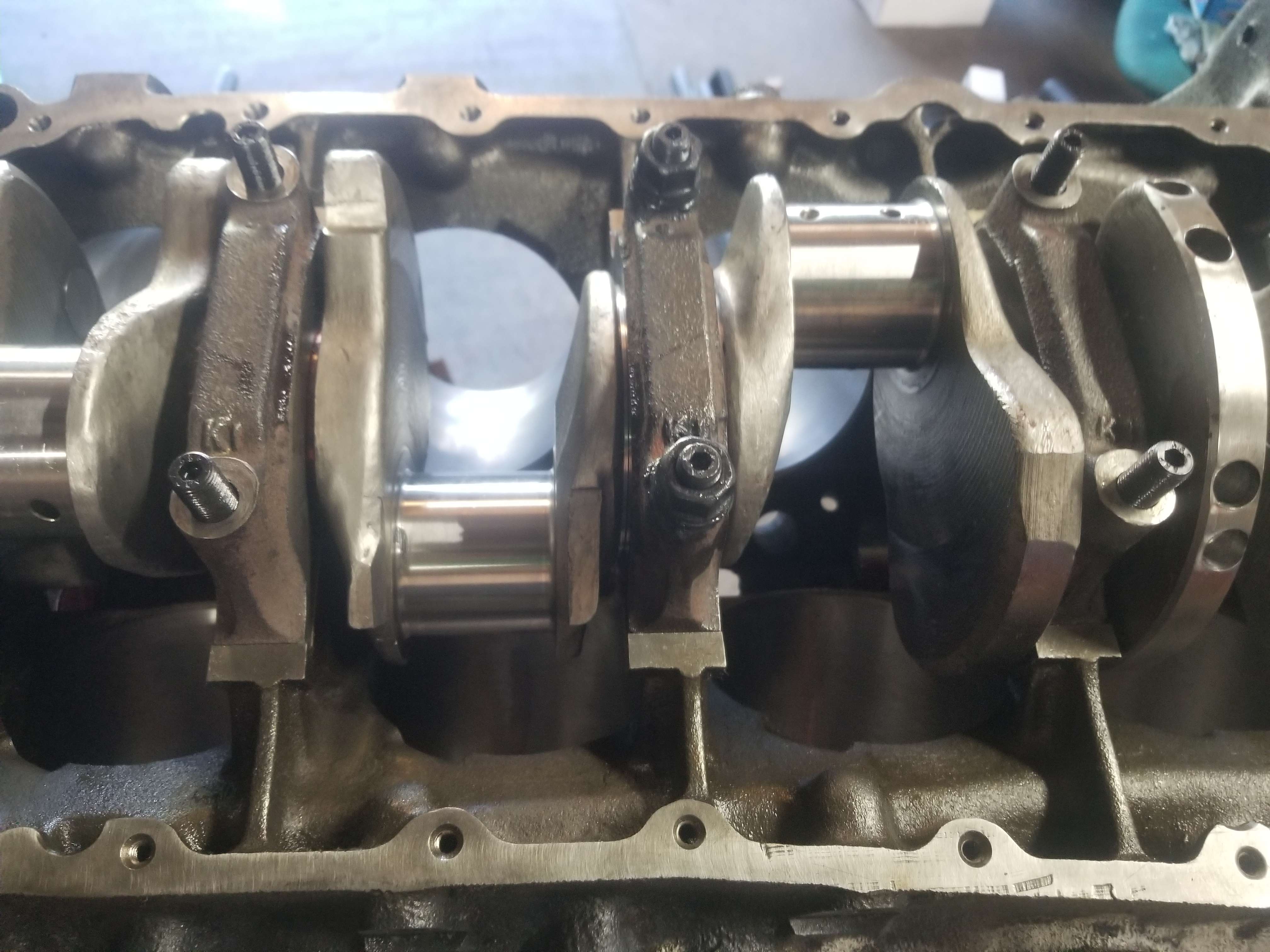

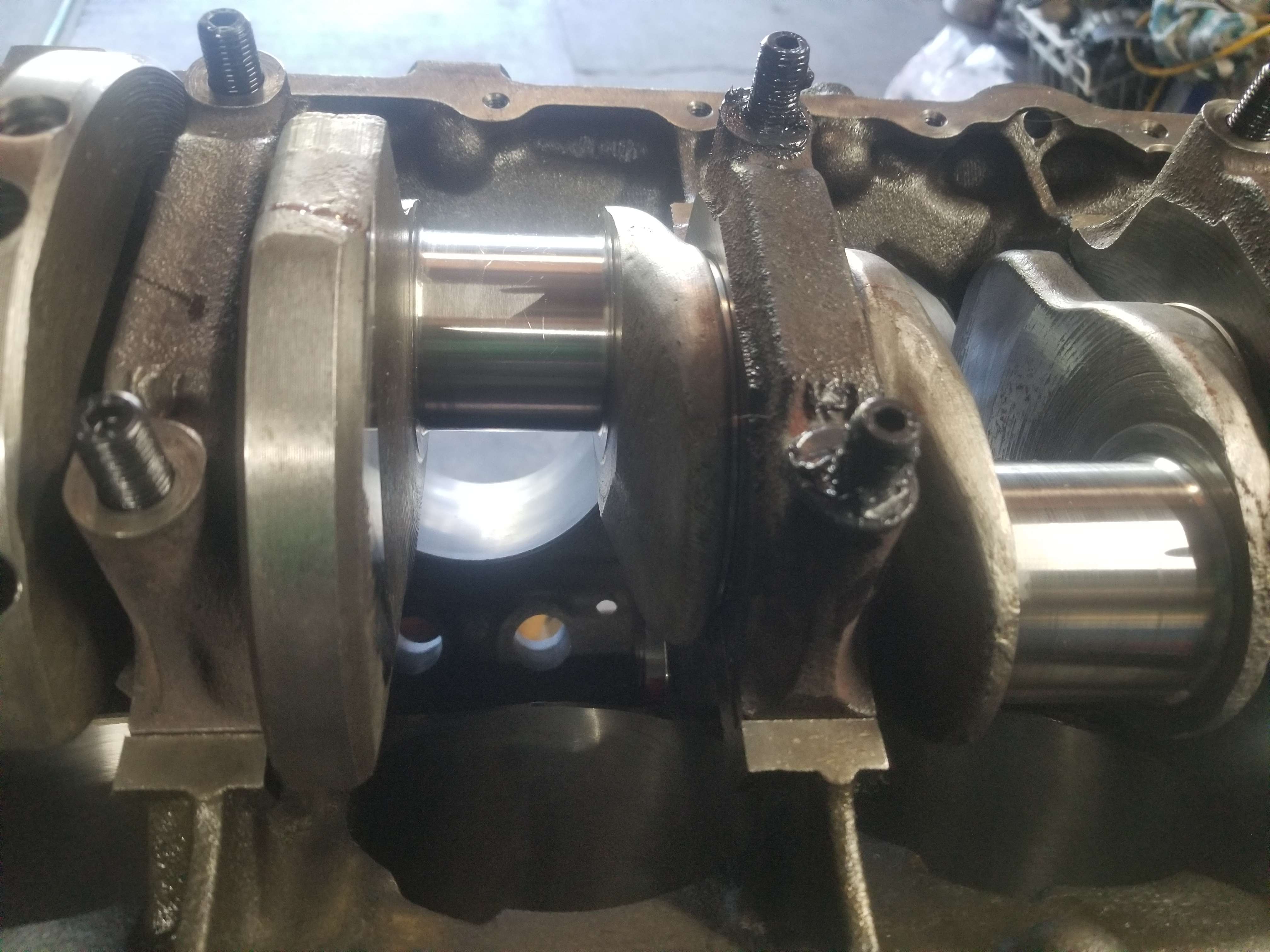

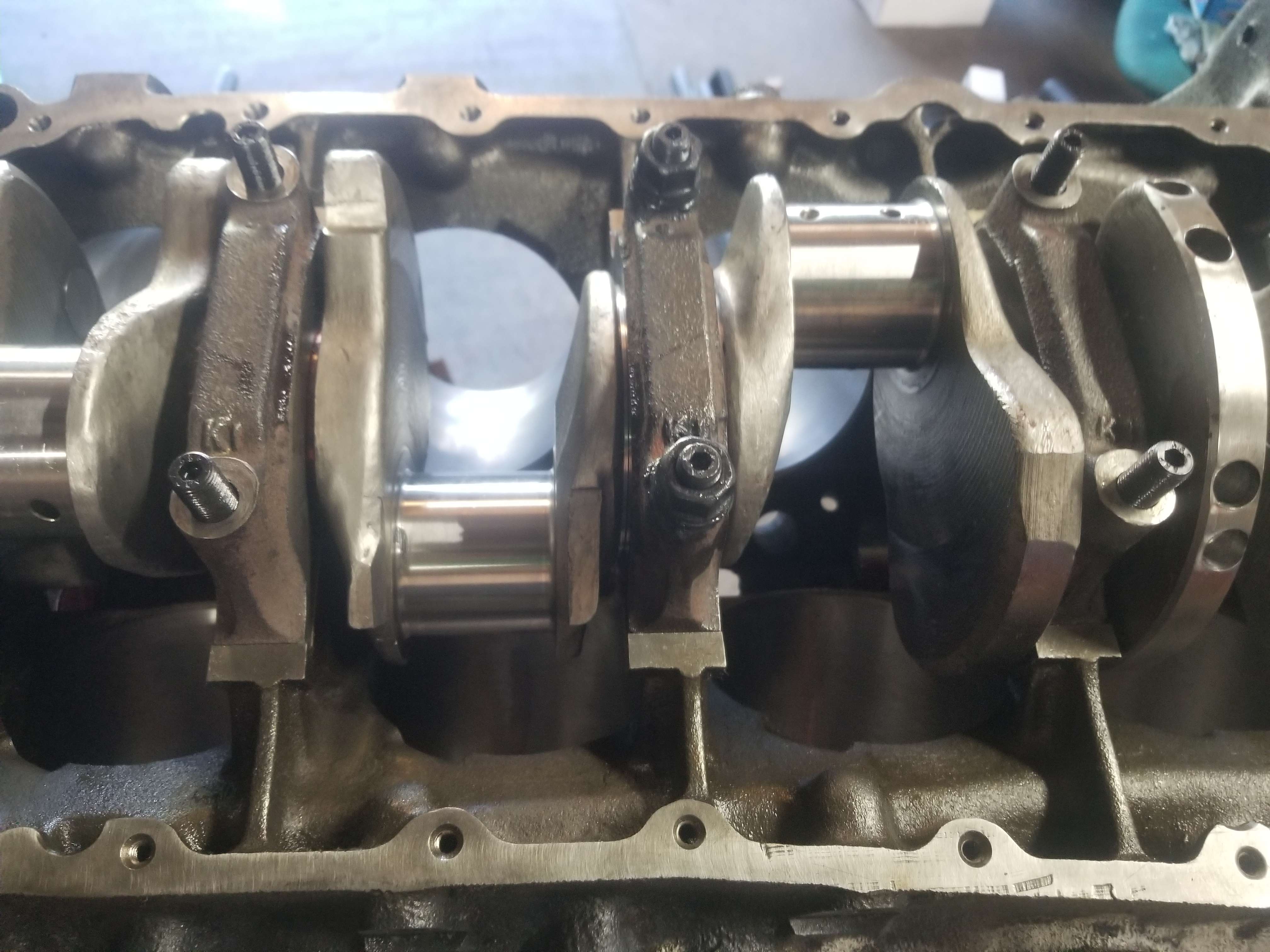

All surfaces cleaned and main bearings are in the block with Permatex Ultra slick applied before carefully placing the 330 crank in place. The bearings are also in the align honed main upper caps.

Ok so I lubed the tops of the bearing caps the same way with Permatex Ultraslick. I tapped the caps all into place. I trimmed off the ears on the AMC 258 main seal, lubed with ATF installed with the groove towards the motor and two small dabs of The Right Stuff. I set the thrust bearing by tightening down the center main bolts with a ratchet then backing off to finger tight. I then spun by the crank by hand tapping back, then foward with my plastic 2 pound dead blow hammer. I then torqued #3 to 80 ft/lbs with ARP lube on both sides of the washer and threads, along with all the mains. I then torqued the rest of the mains to ARP torque specs. The crank spins very easily by hand. I measured .008" for thrust clearance. .007" is loose and .009" is tight.

I just caught up on your Olds 358 build, looks great. You are making lots of progress.

Well, all the piston pin clips are in and I drew way too much blood installing them. Pretty much a PIA to do without the right tool. I talked to Cutlassefi about positioning these rods on the crank. Even though they are centered, one side is slightly wider, like .005" and goes towards "the cheek of the crank". I measured all of them with a caliper and marked with a small green dot on the wider side to position them properly on the crank.

The first piston is in! I wiped the cylinders with ATF a couple of times, looked pretty clean. I see what was meant about ring compressors in another thread. The ratcheting band ring compressor I bought is useless! I actually ended up using my adjustable wrinkle band ring compressor. I positioned all the rings per Mahle's diagram. I put the lube that came with the Molnar rods on the cap bolts. I need to find the torque specs, I will contact Mark, if needed. It involves a torque angle gauge.

Last edited:

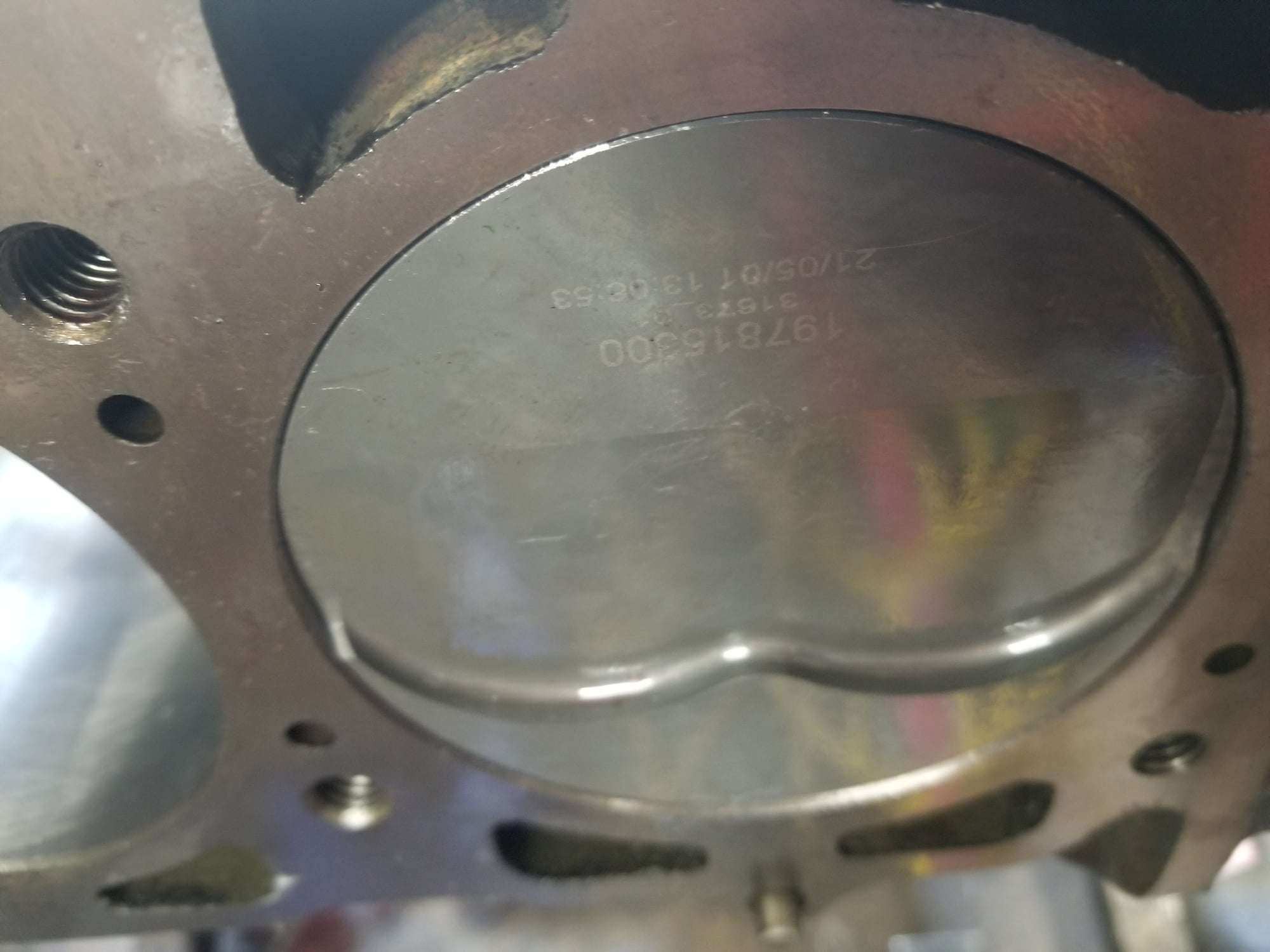

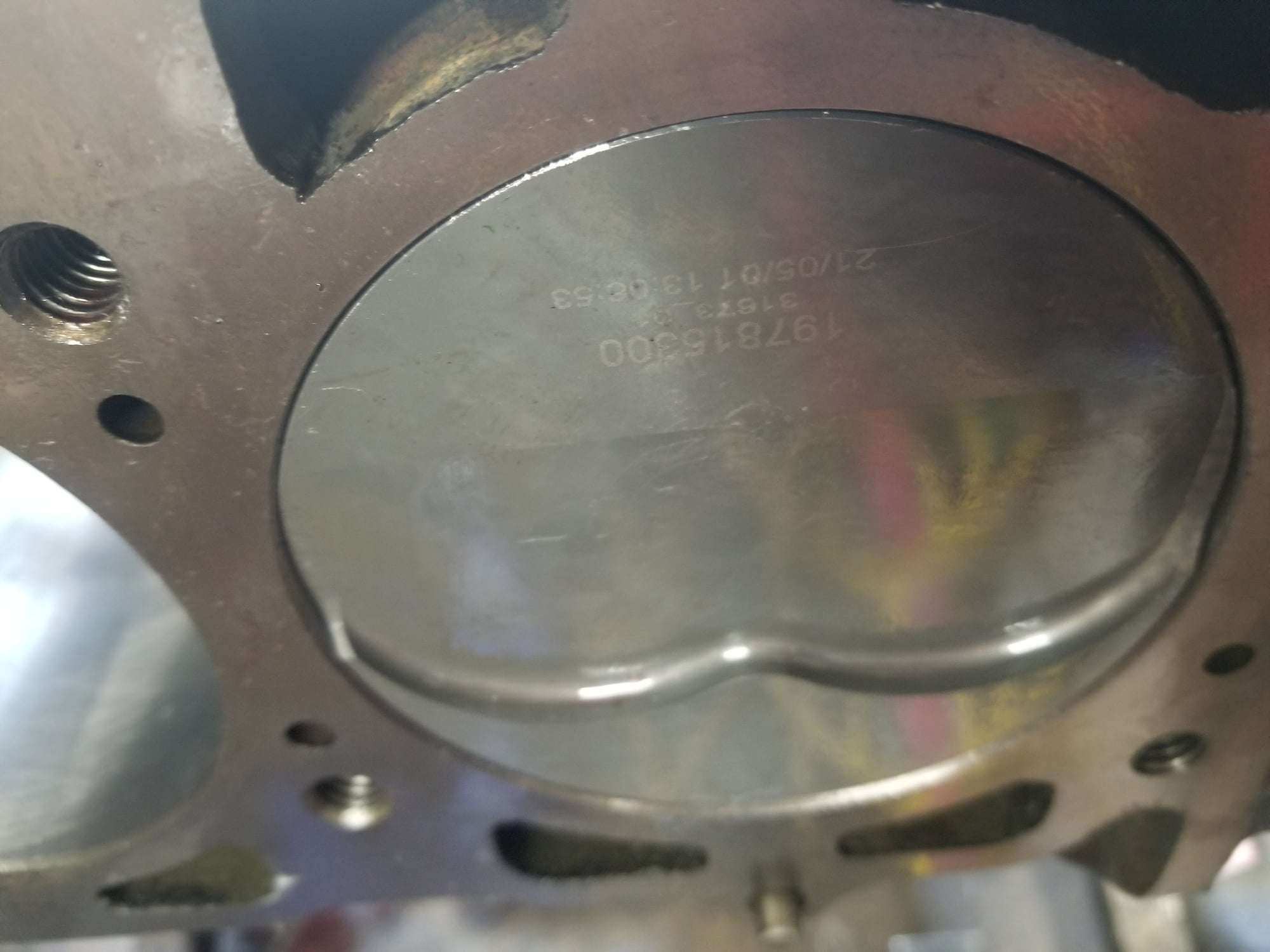

I need to ask, do all the pistons have this imperfection or they way it was machined in this area that's circled. When I look at that picture it looks like a piece of piston missing and I know it's not.

Your doing a great job putting that engine together, l like that you planned it out and taking your time.

Your doing a great job putting that engine together, l like that you planned it out and taking your time.

Yes but that one happens to be the worst. I think Mahle rough machined them there because they are coated. They are a nice piston otherwise. I actually had to remove that piston. It should have been right but was not. It appears the Molnar marked side is the wide side. The next rod would not go on the crank. I went to the other cylinders, paired pistons without rings and sort of put on the caps, they all fit as they should. I numbered them for each cylinder they came out of. I may just have to flip cylinder to cylinder. I will remove the rings and check those two as well. Only a minor setback, I want this build right and to live a long life.I need to ask, do all the pistons have this imperfection or they way it was machined in this area that's circled. When I look at that picture it looks like a piece of piston missing and I know it's not.

Your doing a great job putting that engine together, l like that you planned it out and taking your time.

View attachment 202763

Ok, I have a better understanding what they did, never seen that before on a new piston.Yes but that one happens to be the worst. I think Mahle rough machined them there because they are coated. They are a nice piston otherwise. I actually had to remove that piston. It should have been right but was not. It appears the Molnar marked side is the wide side. The next rod would not go on the crank. I went to the other cylinders, paired pistons without rings and sort of put on the caps, they all fit as they should. I numbered them for each cylinder they came out of. I may just have to flip cylinder to cylinder. I will remove the rings and check those two as well. Only a minor setback, I want this build right and to live a long life.

- Status

- Not open for further replies.

Similar threads

- Replies

- 11

- Views

- 236

- Replies

- 5

- Views

- 239

- Replies

- 4

- Views

- 247

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.