Do you guys recommend buying a new aftermarket Z bar, or locating a factory one, and IF needed... strengthening / welding / modifying it to fit properly?

Stock linkage Z-bar modification- SUCCESS!

- Thread starter Bonnewagon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

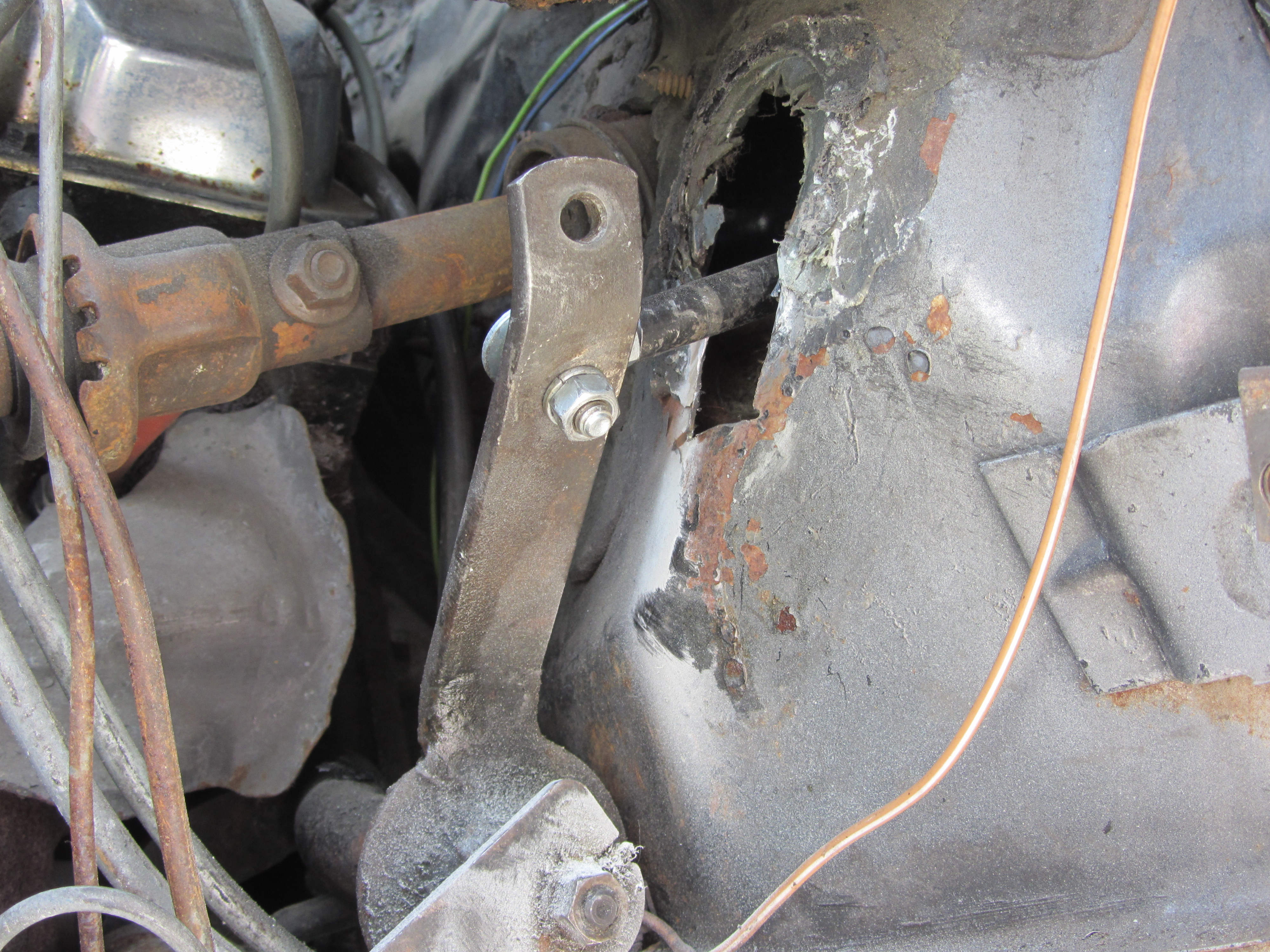

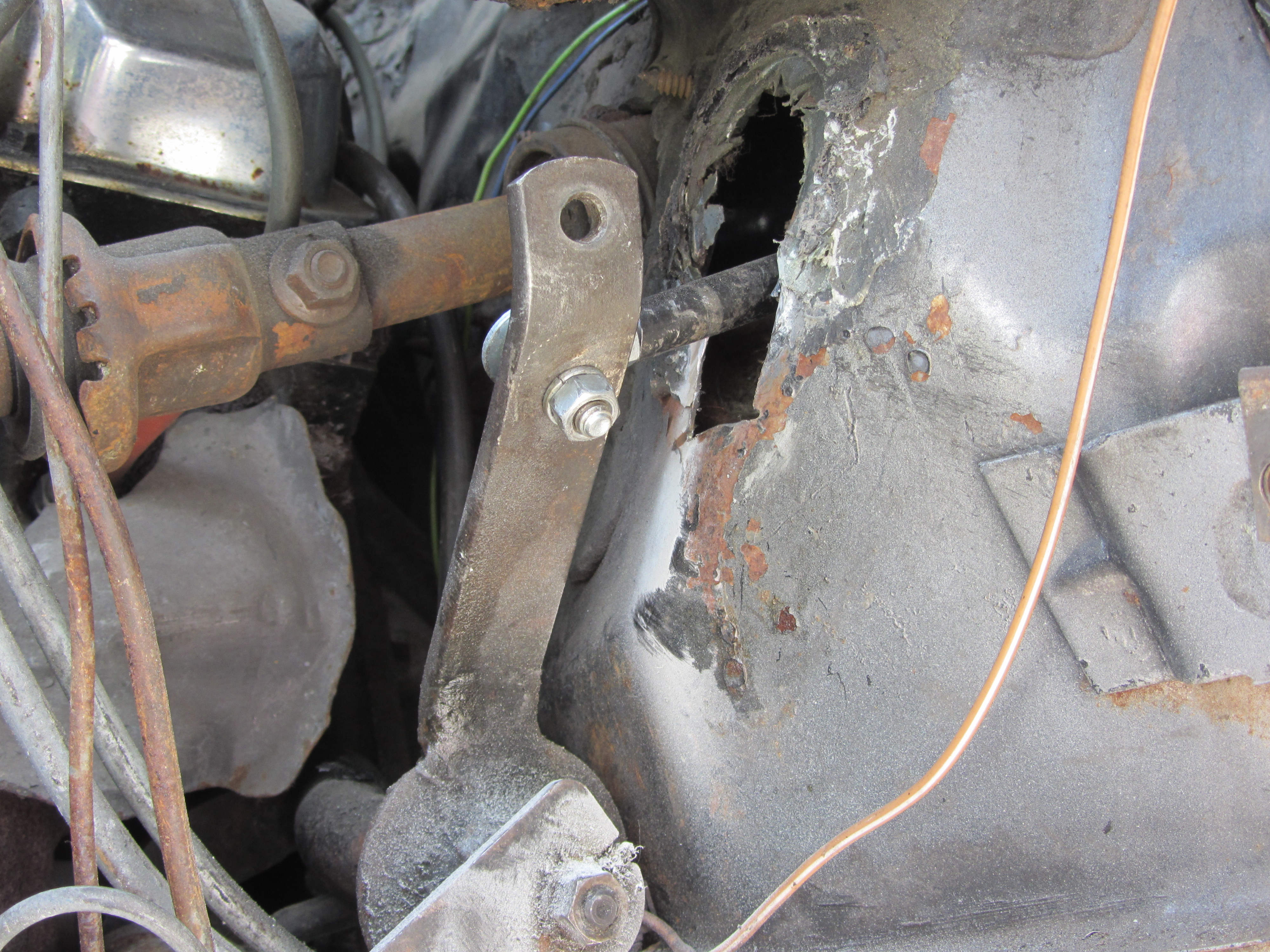

UPDATE: Finally I got the time and a dry day to get back to this. JAMCAR I don't know if one is better than the other. I was fortunate enough to get a Malibu with factory manual transmission so that is what I used. I would hope the reproduction would be better made but I would not count on it. My Clutch and Flywheel Handbook assumes that the factory stuff is weak and advises to strengthen it. Anyway I got the Z-bar out after loosening the entire inner fender. Don't even try it without doing that. Once out I measured the holes in the bar and found they were two different sizes. The larger was a hair smaller than 3/8" (metric?) so I planned on using 3/8" grade 8 bolts. I drilled out both the pushrod hole and the GAGE hole to 3/8". I found a steel bar exactly the right thickness, length, and width I needed and I drilled two 3/8" holes to mount the bar to the Z-bar. Then I drilled three 5/16" holes for the clutch push rod. I did three so I had a selection to test the clutch pedal travel. I scrounged some grade 8 bolts the length I needed and bolted the extension to the Z-bar using lots of Locktite.

Now, to get the Z-bar back into position with the longer extension was pretty easy because I had loosened the inner fender. But I had to really pry it back out of the way to get access to the frame area. I slipped the Z-bar back into place on the block stud and re-bolted the bracket to the frame. Once all was hooked up I realized that the longer bar now hit the canister for the heat riser valve. I could not get the same retraction travel that I had before. This is where it is great to have the SpeedDirect adjustable linkage. I merely adjusted out the top rod to make up for the now shorter lower rod. How neat is that?

Now, to get the Z-bar back into position with the longer extension was pretty easy because I had loosened the inner fender. But I had to really pry it back out of the way to get access to the frame area. I slipped the Z-bar back into place on the block stud and re-bolted the bracket to the frame. Once all was hooked up I realized that the longer bar now hit the canister for the heat riser valve. I could not get the same retraction travel that I had before. This is where it is great to have the SpeedDirect adjustable linkage. I merely adjusted out the top rod to make up for the now shorter lower rod. How neat is that?

OK now to see what I have under there. I adjusted the lower rod with the stud in the closest hole to stock. No good, not enough travel. Next hole was better, but to keep the pedal free play the pedal was still too close to the firewall for my liking. The third and farthest hole from stock was the best. I have plenty of free play and the clutch is totally disengaged way before the pedal gets anywhere near the firewall. That is exactly what I wanted. The change in ratio at the lower Z-bar arm gave me all the travel I needed so I could have both things. The change in pedal effort was not really that noticeable but I will evaluate that after a drive. I also had just enough time to change out my speedometer driven gear while the car was up in the air. I had mistakenly counted seven teeth on my drive gear when I fixed the trans last winter. Turns out it had eight teeth and I miscalculated the needed driven gear. Ooops. Anyway now it is done. I got this finished right before another deluge from the 2019 Monsoon season. I need to take the car to one of those roadside radar set-ups that tells you how fast you are going. It is far enough away that I will be able to evaluate the pedal effort properly- in traffic. Another thing I need to do is to move the lower rod from the side it is on to the other side so it is a straighter shot. It is within the range of mis-alignment for the spherical ball end but I would like it straighter. It is also too clost to that part of the bell housing where the starter mounts. Working under there is tiresome so I left it for now. Plus it is raining so hard right now I expect to see Noah floating down my street.

OK now to see what I have under there. I adjusted the lower rod with the stud in the closest hole to stock. No good, not enough travel. Next hole was better, but to keep the pedal free play the pedal was still too close to the firewall for my liking. The third and farthest hole from stock was the best. I have plenty of free play and the clutch is totally disengaged way before the pedal gets anywhere near the firewall. That is exactly what I wanted. The change in ratio at the lower Z-bar arm gave me all the travel I needed so I could have both things. The change in pedal effort was not really that noticeable but I will evaluate that after a drive. I also had just enough time to change out my speedometer driven gear while the car was up in the air. I had mistakenly counted seven teeth on my drive gear when I fixed the trans last winter. Turns out it had eight teeth and I miscalculated the needed driven gear. Ooops. Anyway now it is done. I got this finished right before another deluge from the 2019 Monsoon season. I need to take the car to one of those roadside radar set-ups that tells you how fast you are going. It is far enough away that I will be able to evaluate the pedal effort properly- in traffic. Another thing I need to do is to move the lower rod from the side it is on to the other side so it is a straighter shot. It is within the range of mis-alignment for the spherical ball end but I would like it straighter. It is also too clost to that part of the bell housing where the starter mounts. Working under there is tiresome so I left it for now. Plus it is raining so hard right now I expect to see Noah floating down my street.

Last edited:

Mark, would you recommend this mod from the start on a new swap/install, or would you consider this a "car to car" situation? I will be using SD linkage and a stock style Z bar. It seems the 2" bolt hole to bolt hole extension is a lot... Thanks for updating this thread.

JAMCAR, no, I don't recommend just changing stuff without testing the stock stuff first. I originally used all stock components and had no problems for many years. I have concluded that after 10 years of wear my flywheel and clutch pressure plate had worn enough to cause the diaphragm clutch's belleville spring fingers to raise up higher than when new. My free play diminished to the point of causing the throwout bearing to be in contact with the pressure plate fingers and it eventually ruined the bearing. This is what caused my need for more travel at the throwout bearing. It would have been simple to just change everything for new parts but Pontiac 301 manual flywheels are pretty scarce. Besides that I was using a used flywheel that has been surfaced once already I was not willing to cut it again when it was still in good condition. The pressure plate was also in good condition- no cracks or heat checks. Both had worn down evenly and smoothly causing more travel for the pressure plate yet they worked like new. I merely disc sanded the surfaces to get them very smooth and re-used them as is with a new clutch disc. The biggest problem I see with what I did is that the lower clutch rod is not parallel with the transmission input shaft center line. That may cause the clutch fork to press the throwout bearing downward against the surface of the collar on the transmission front bearing retainer. As always- you change one thing and it affects several others. I may try a different approach. I may take the Z-bar out again and try drilling holes in the upper arm. By lowering the upper push rod's attachment point I can change the ratio there instead of down below. But I have to be carefull that I don't cause the upper rod to interfere with the hole in the firewall. Because the upper rod is much longer than the lower rod the change in angle should be less severe. A lot of work? Yes, but isn't that what this hobby is all about? You try something and if it doesn't work right you take it all apart and try something else. Never be afraid to back up and regroup. Stay tuned......

Another UPDATE: I screwed myself by adding bolts to the lower Z-bar arm. They are hitting the EFE valve. If I didn't have one I would have all the range I need but it is on there- rust and all. Where before I had a full range of swing before and after perpendicular , now I have little forward swing past perpendicular away from the clutch fork. That means most my travel is on the clutch fork side of perendicular and that is not good. What you want is equal swing on both arcs. However even that limited swing is getting me the total travel I wanted. I was wondering why I needed so much extension to get what I wanted- JAMCAR saw that- so I am back rethinking this. I will next look at the upper Z-bar arm and see what I can do. Oh, and the speedo gear change worked out well. Two more teeth changed the reading by 10 mph.

Yesterday I got up under there again and eyeballed what I could do. I removed the extension bar and bolts and found I could move the bare lower Z-bar more forward than before. The stock lower push rod with the big bent end had hit the EFE valve but with the SD bar I was able to place the small bolt head on the EFE side and the spherical end on the starter side. That got me some more forward travel. Then I grabbed a long chisel and a BFH and bent the EFE mount just a little. That moved it away from the lower rod and I got even more travel. Then I banged the starter heat shield back getting the last bit of travel that was available. Now the lower rod is going as far forward as is physically possible. That got me so much more travel I had to compensate at the upper push rod by shortening it. The lower rod is positioned better too and is parallel with the transmission input shaft center line like it should be. Unfortunately the ratio is still the same as stock and the pedal travel is inadequate for what I need. Today I will attempt to drill the upper Z-bar for a different attachment point for the upper rod. Now that I have full travel of the lower rod changing the ratio should work out.

SUCCESS!!!! This time I yanked the entire inner fender out of my way. I double-checked inside the car to see if I could get away with lowering the upper rod attachment point on the upper Z-bar. By lowering it the bar would pass through the firewall much lower than stock. Luckily there is nothing there to interfere. Now to drill a hole in the upper Z-bar arm a little bit further down. YIKES!!! What is this thing made of? Even Cobalt bits would not even scratch it. Nothing worked until I tried a small grinding stone used with a Dremel tool. That managed to get a tiny spot going. I tried diamond bits but they just got hot and failed. So back to the stones which did not last long but penetrated a bit more each time. Then I found an old very hard pointy stone that I saved from my father-in-law's stuff, 50's vintage. That did the trick. It was very slow going but that stone ate the metal away steadily. Then I expanded that with a 5/16" Cobalt bit. This took a long time but eventually I had my mounting hole. I was right, the upper rod now passed through the firewall about an inch lower than stock. I removed the bellows and cut out some firewall with the Dremel cutting disc. Hooked it all up and tested it. BINGO! I have all the free play I want and the clutch is totally disengaged with my pedal about two inches from the floor. Perfect. So extending the lower Z-bar arm was not the way to go for my car. If I had the correct EFE valve for a manual transmission it would not have been a problem. The valve I have is for an automatic and is right in the way of the Z-bar travel. The manual type vacuum motor mounts up on the head and a long rod works the valve. Impossible to find. So shortening the upper Z-bar arm does the same thing- changes the ratio and moves the lower rod farther relative to the upper rod travel. The lower rod is perfectly aimed at the clutch fork. The upper rod clears the firewall. I don't notice any real increase in pedal effort but again, let me sit in traffic and I may feel differently. Now to fill the old firewall hole and re-install the inner fender. WHEW!!! I knew there had to be a way.

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 437

- Replies

- 7

- Views

- 421

- Replies

- 0

- Views

- 177

- Replies

- 14

- Views

- 834

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.