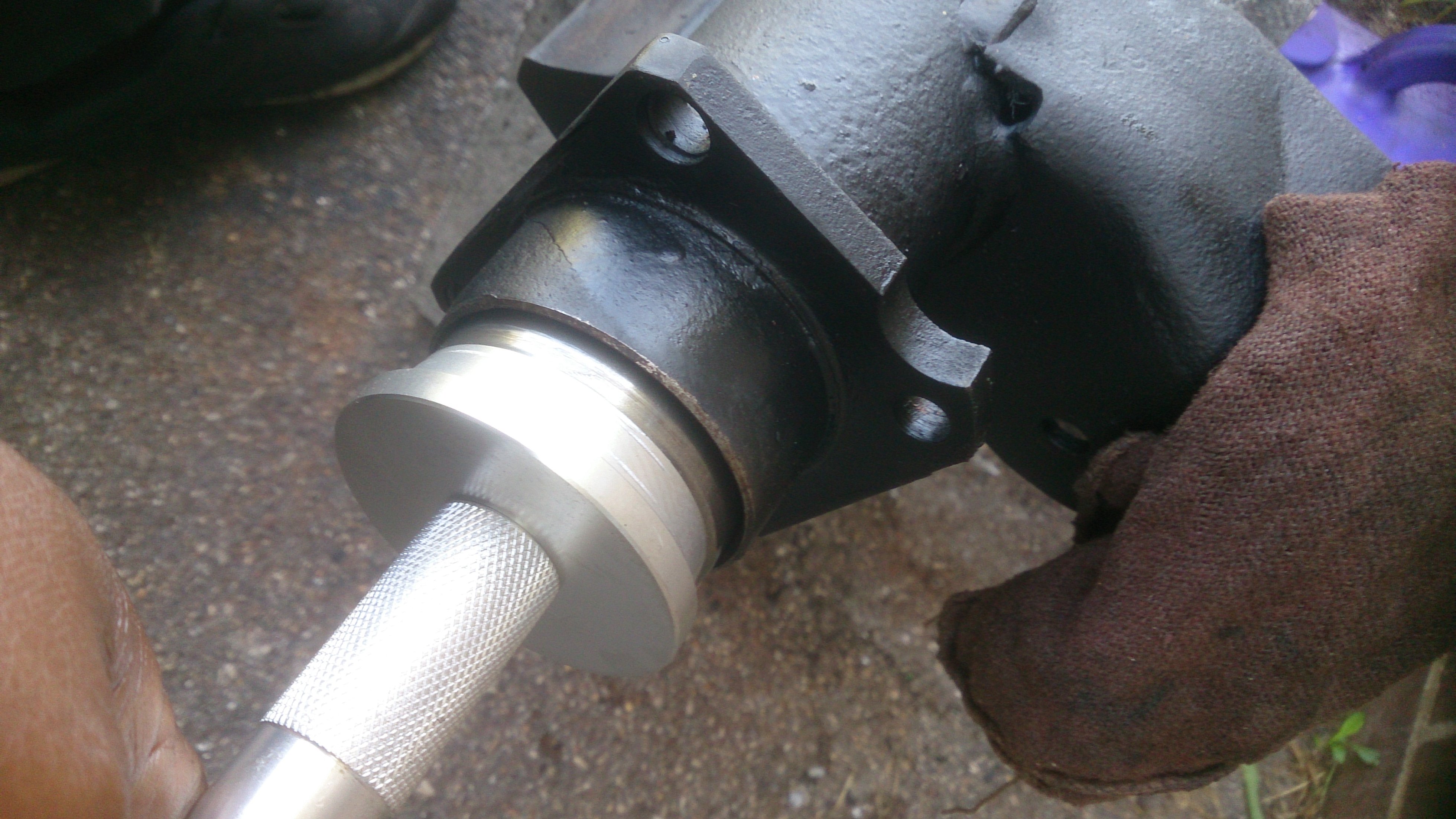

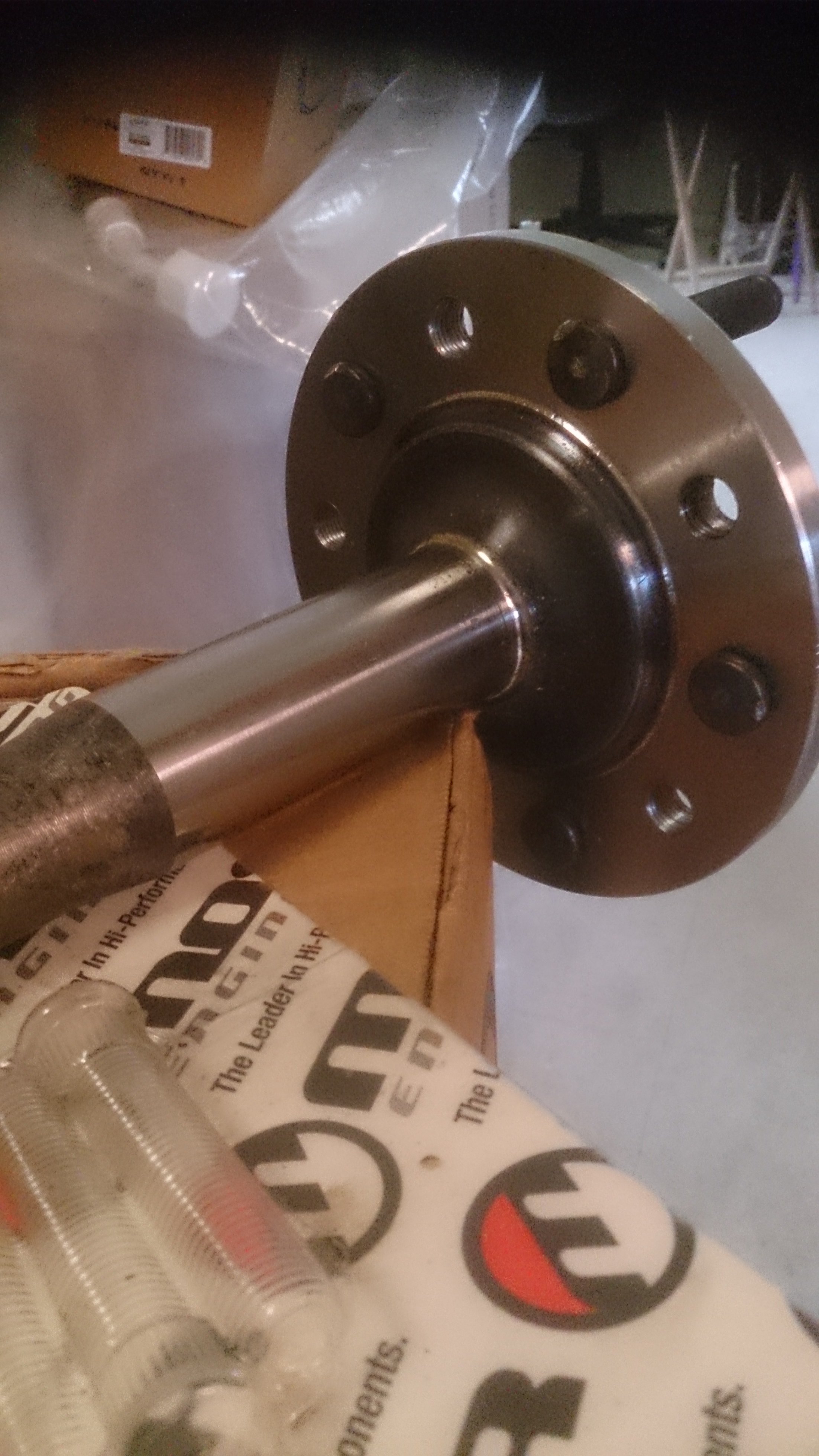

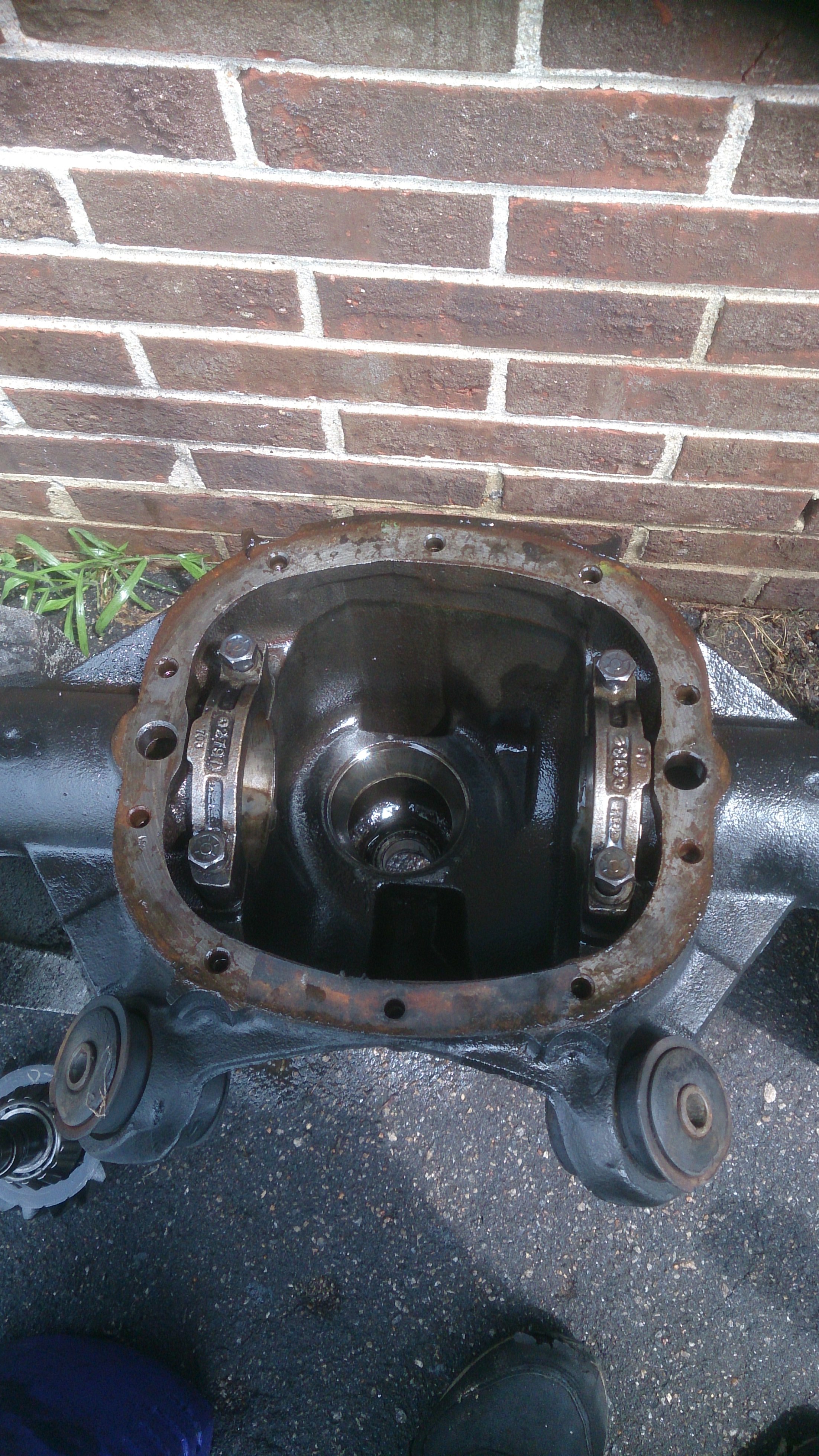

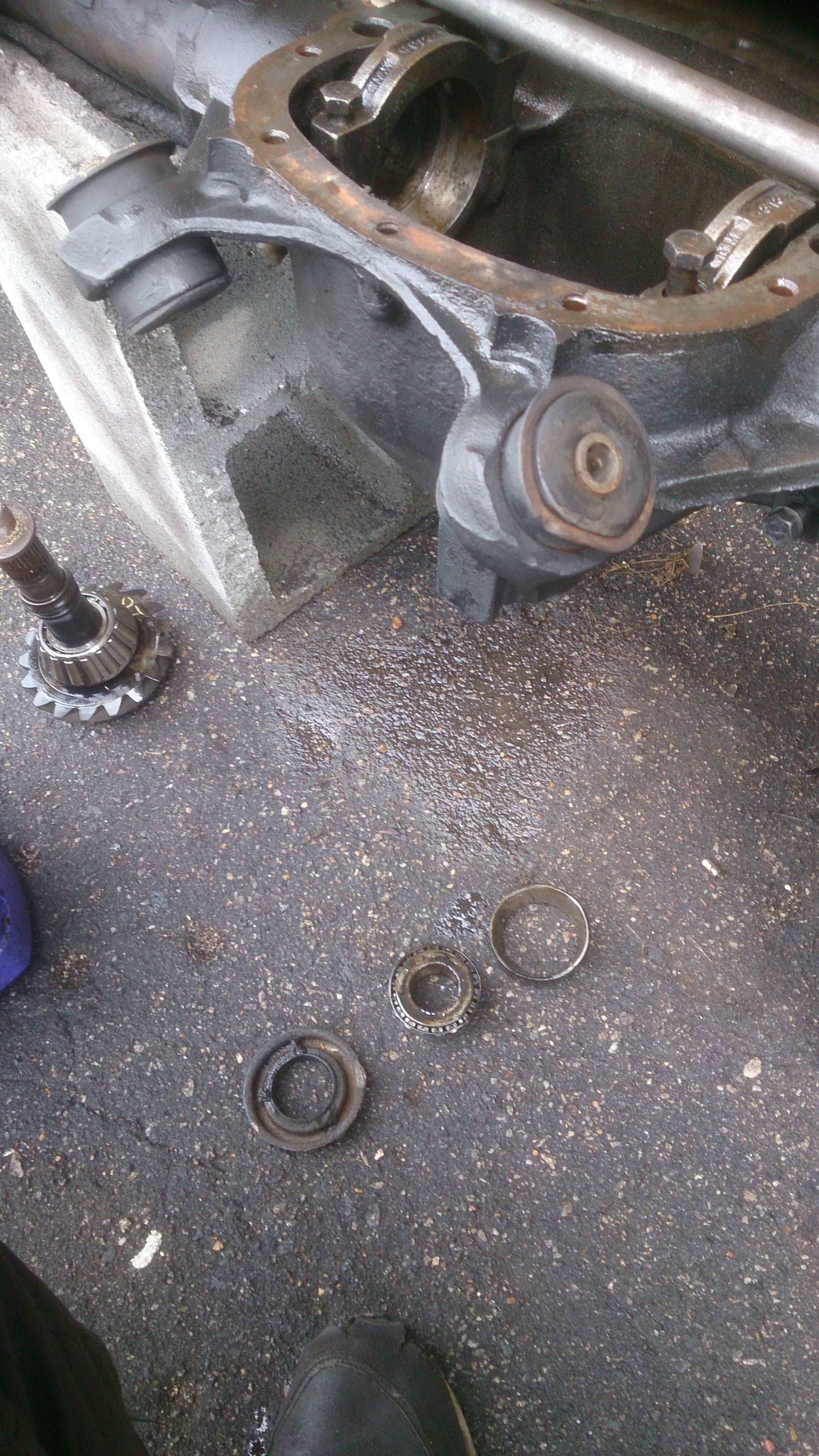

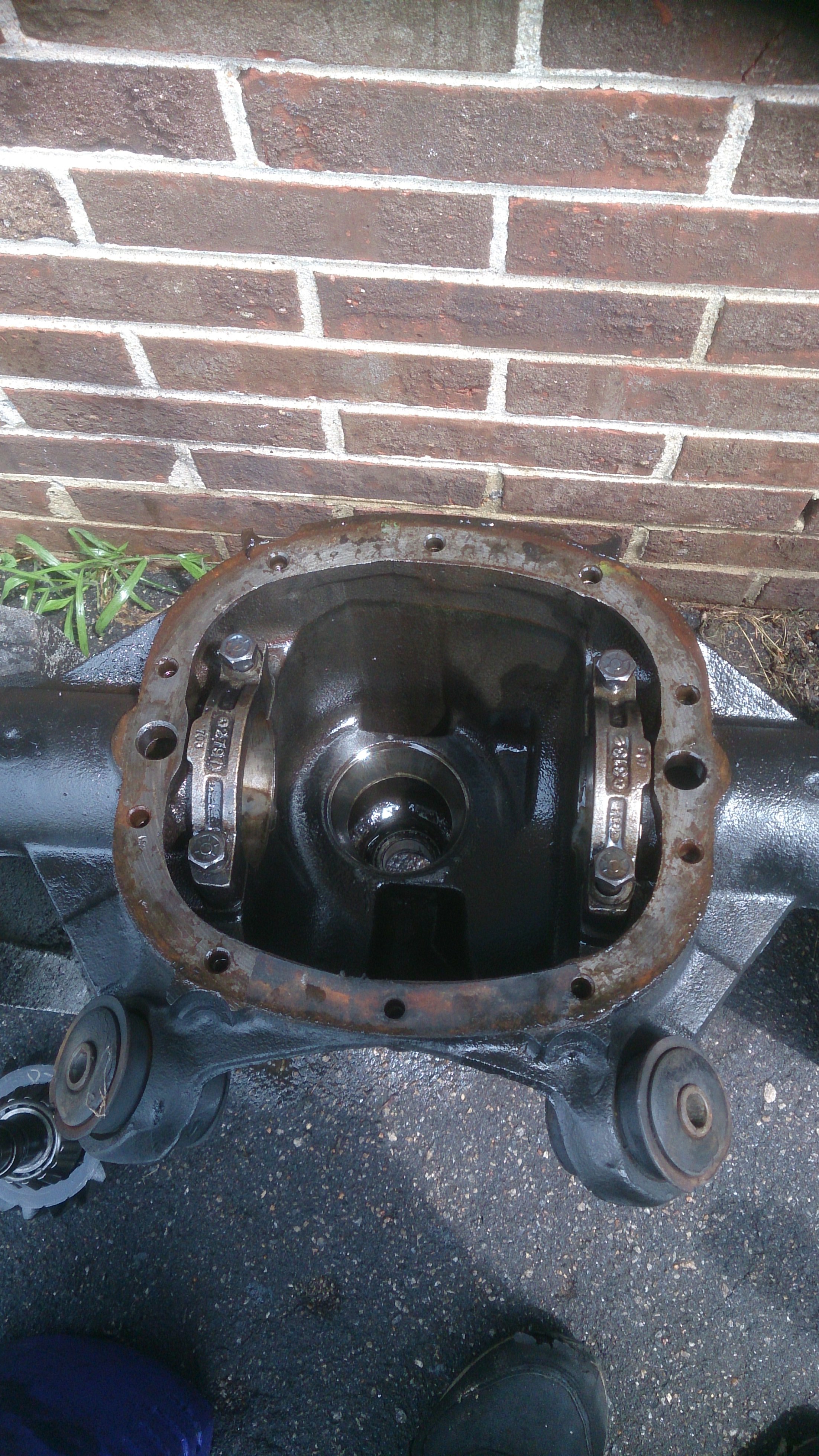

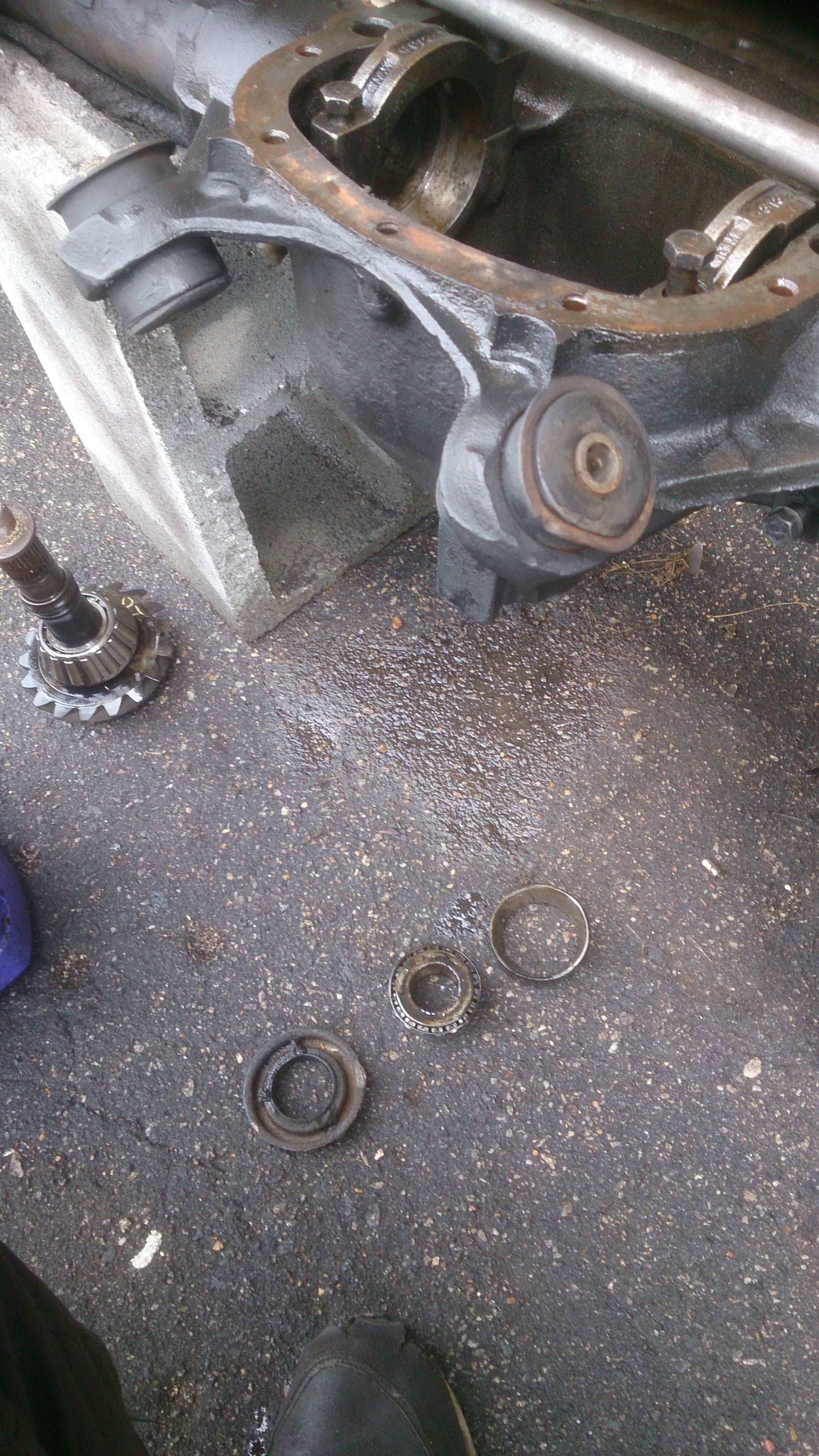

Well, I got some time to to finish disassembling the rear. I removed the axle bearings, pinion races, and cleaned the inside of the housing.

I used a 6ft pipe from the local Home Depot to knock out the bearings. I just used spray Engine cleaner to clean out the oil. Then I used some rags in the tubes to push out any debris in there.

I used a 6ft pipe from the local Home Depot to knock out the bearings. I just used spray Engine cleaner to clean out the oil. Then I used some rags in the tubes to push out any debris in there.

Last edited: