One Week or Thereabouts Later...………...

So I took everything both positive and negative that visitors to this thread of mine had to offer and came up with this.

Meet my new little, not so pretty (I warned you) little friend! From fixed crotch to floating crotch-the bottom of the Vees- it measure a little over 2 inches.

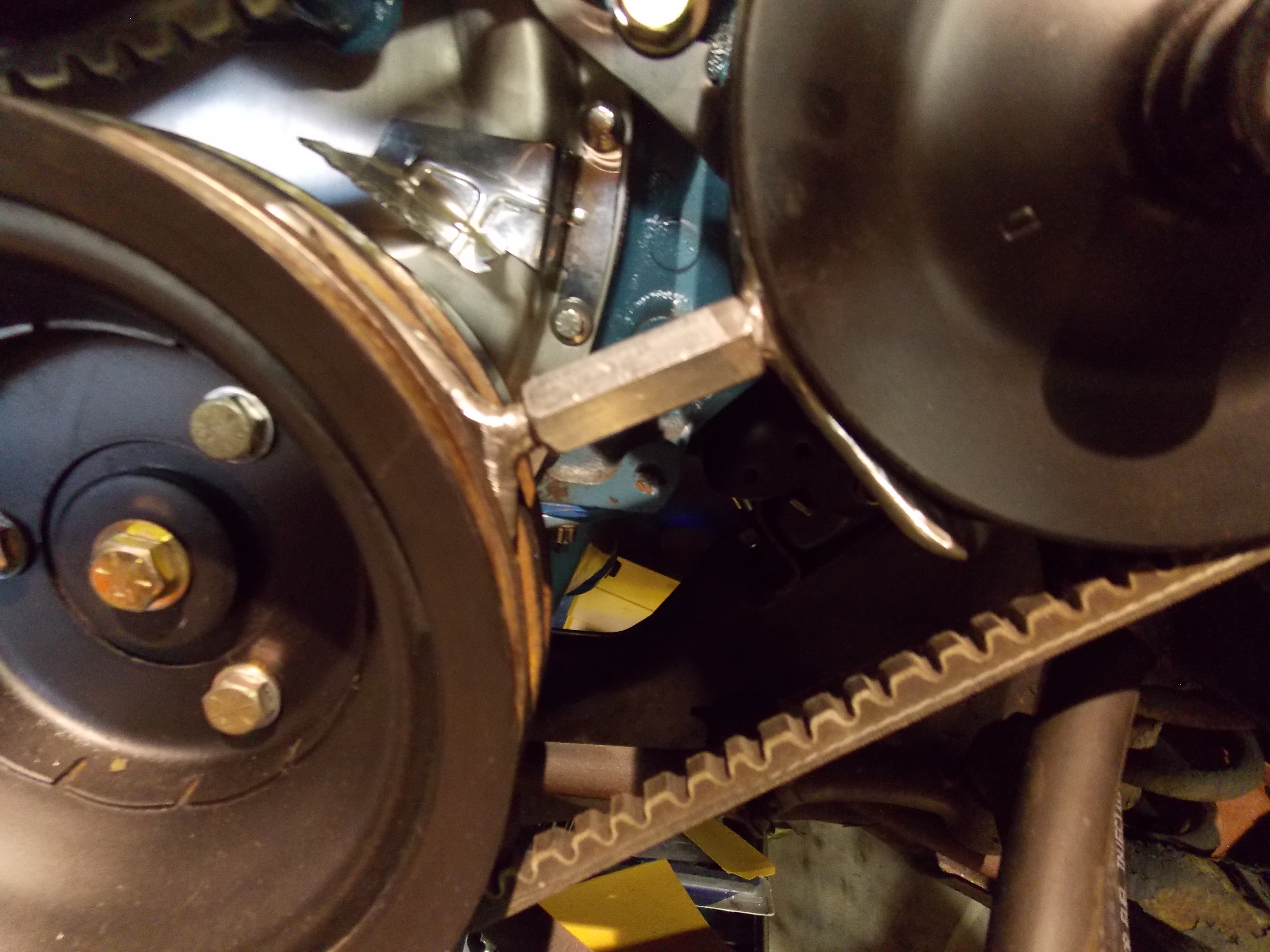

Just a detail shot of how the "fixed" crotch, or maybe call it saddle or cradle is free to be removed from the body of the tool. The opposing saddle, although seeming to be solidly connected to the center hex body, is actually threaded into it. This makes it able to extend and retract when a wrench is applied to the hex.

This second detail shot shows how the hex body was drilled internally to remove a portion of its threads. Being drilled this way, sets the final inner diameter for the "fixed" end at 3/8ths inch and allows the fixed saddle to pivot or swivel freely. Being able to do so allows some compensation for mis-aligned pulleys; just don't expect the belt to last any length of time. The reason this end is termed "fixed" is that, unlike the floating saddle, it cannot be extended or retracted out or into the hex body. Although it can turn 360 degrees, that is as much as it can do. I did mention ugly and the marks on the ears of the saddle are proof of that. I had to inflict them in order to get those ears as flat and extended out as possible; more on that in the Coles Notes below.

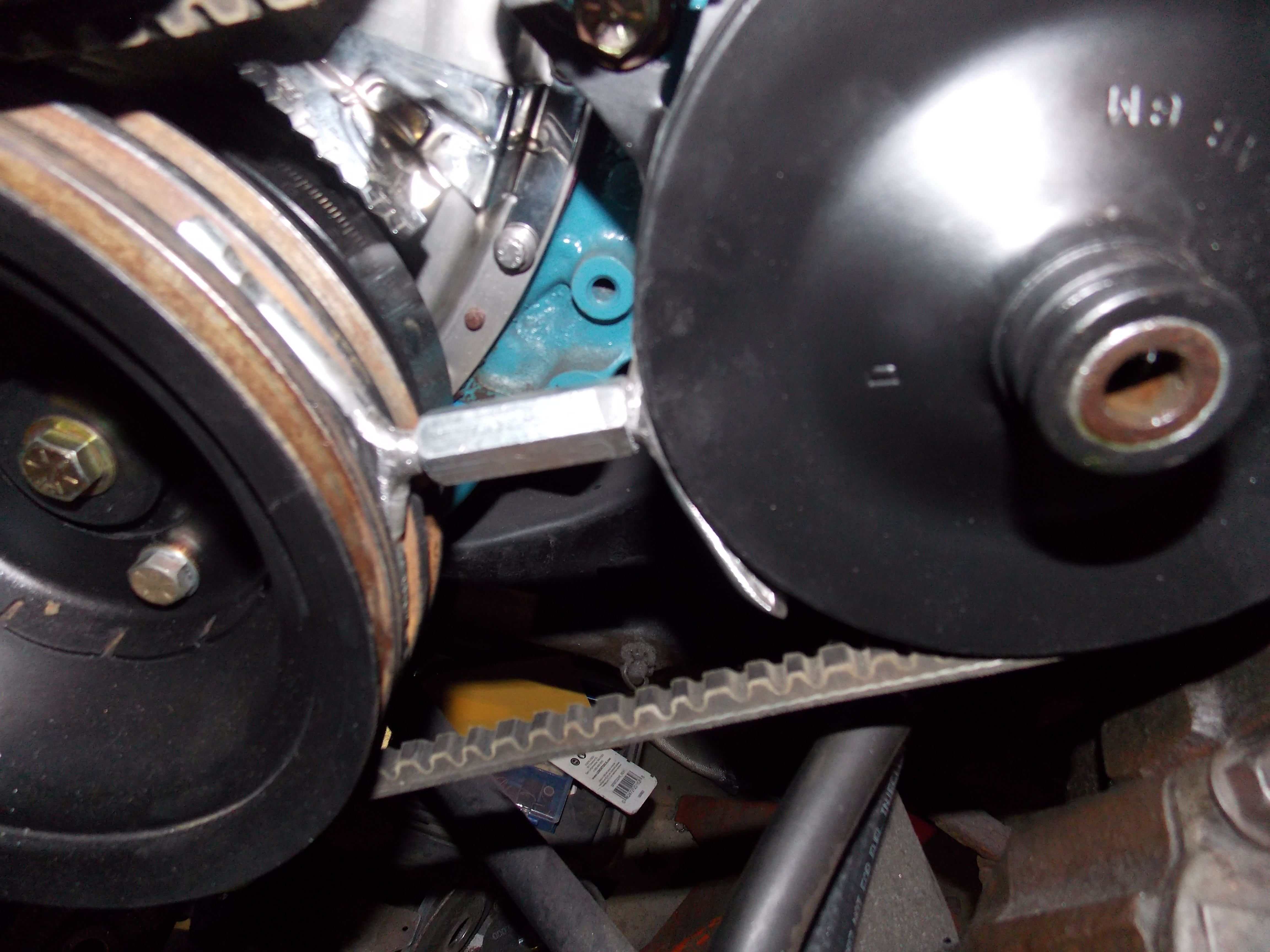

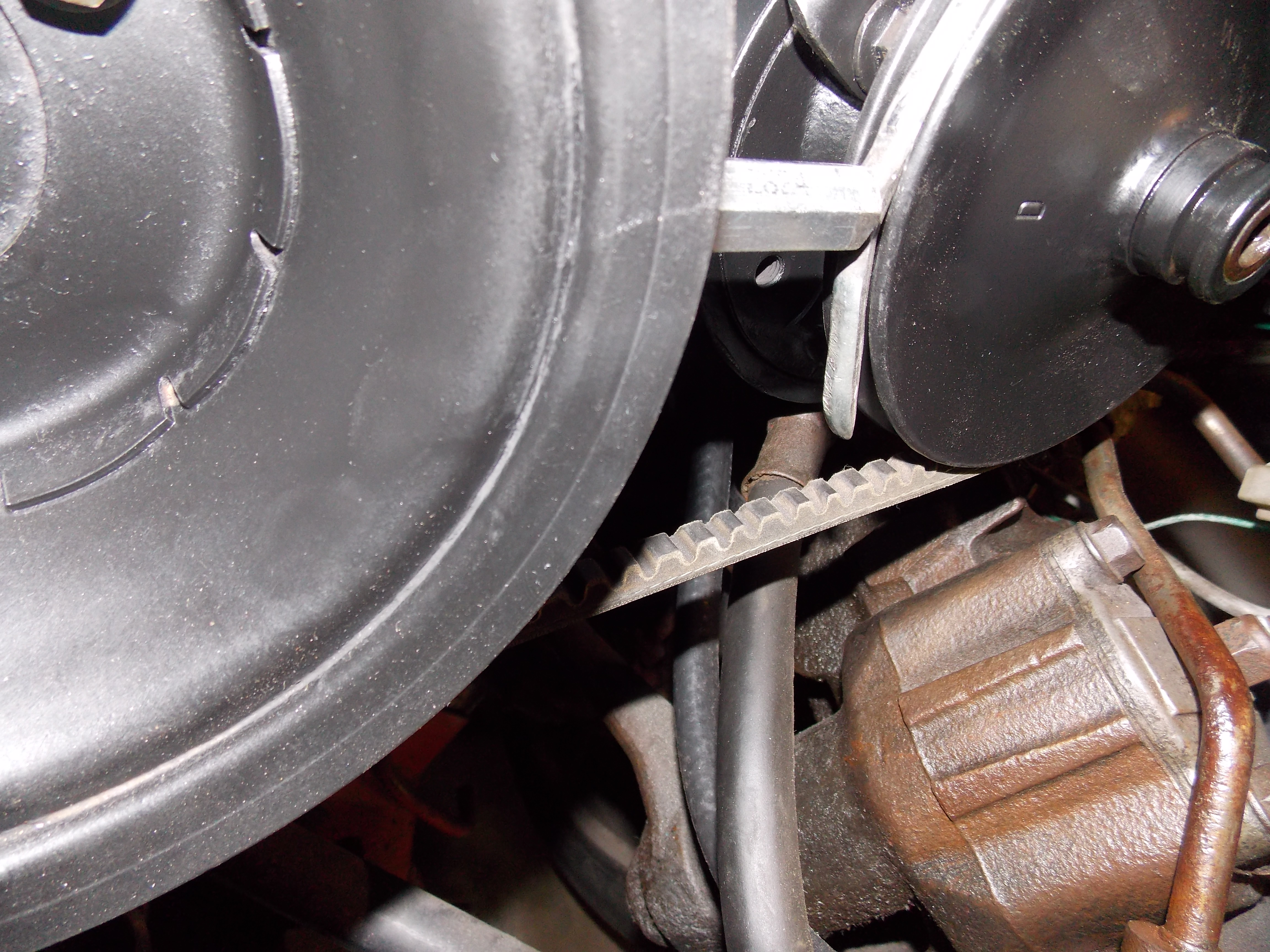

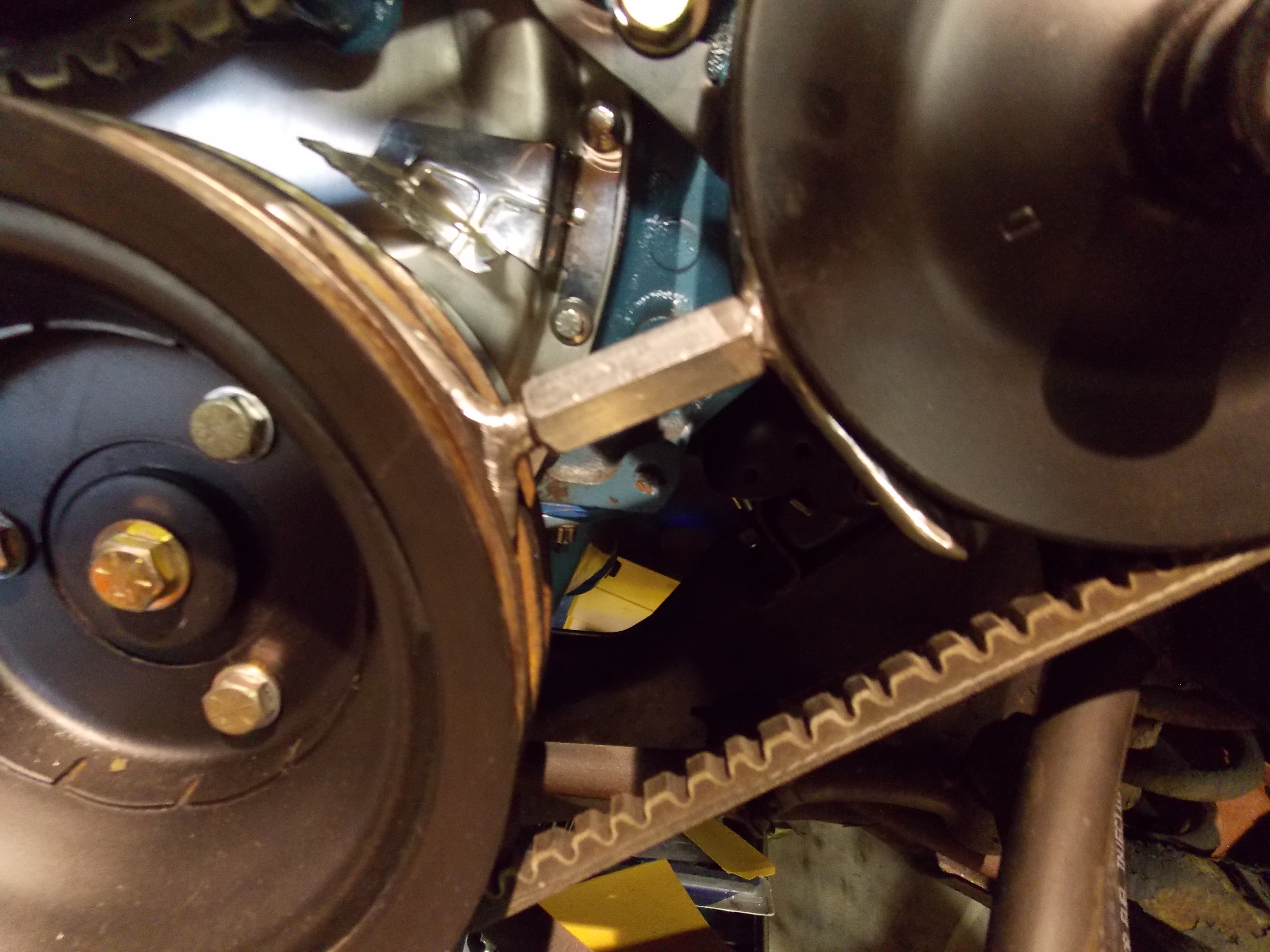

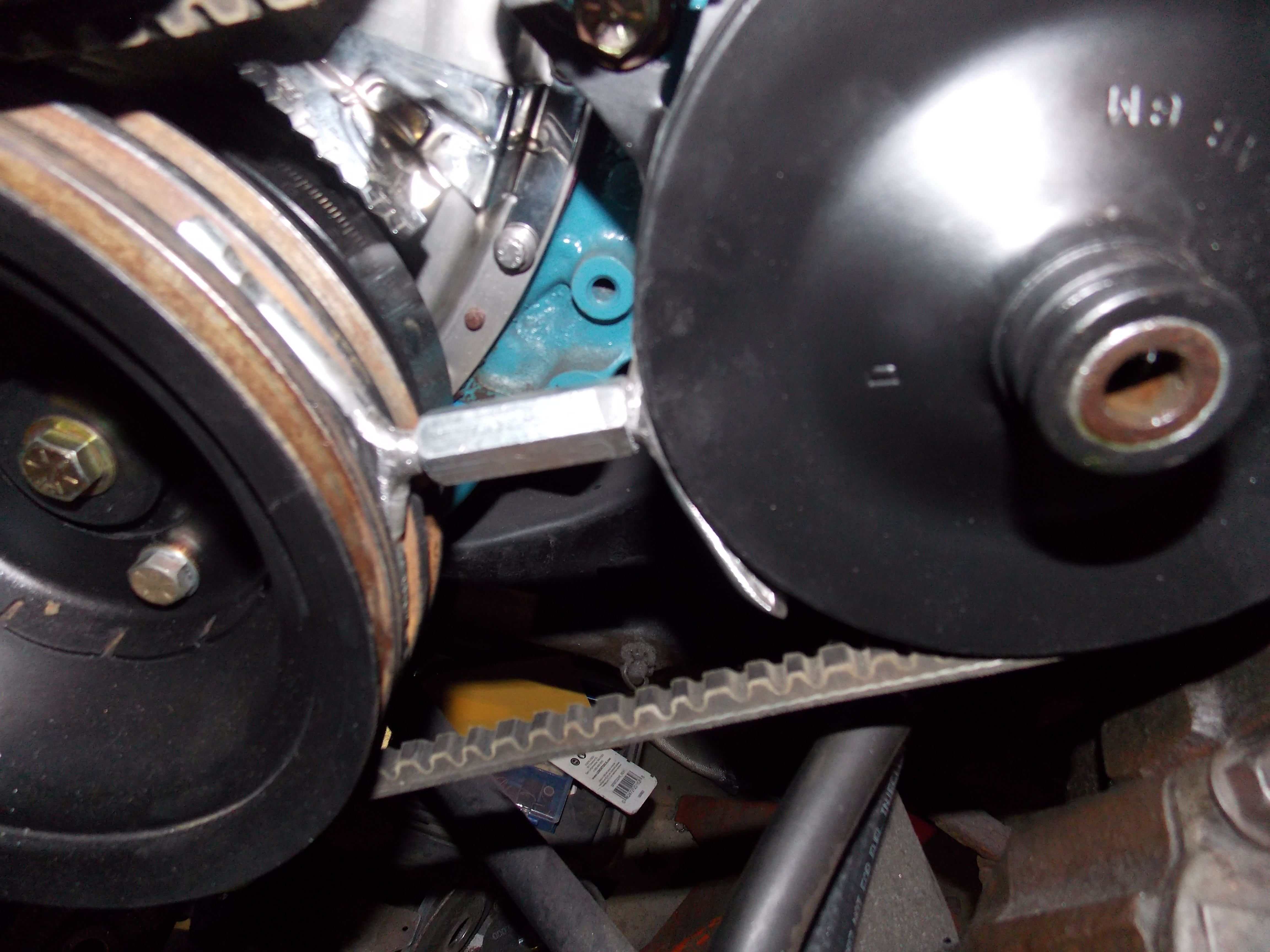

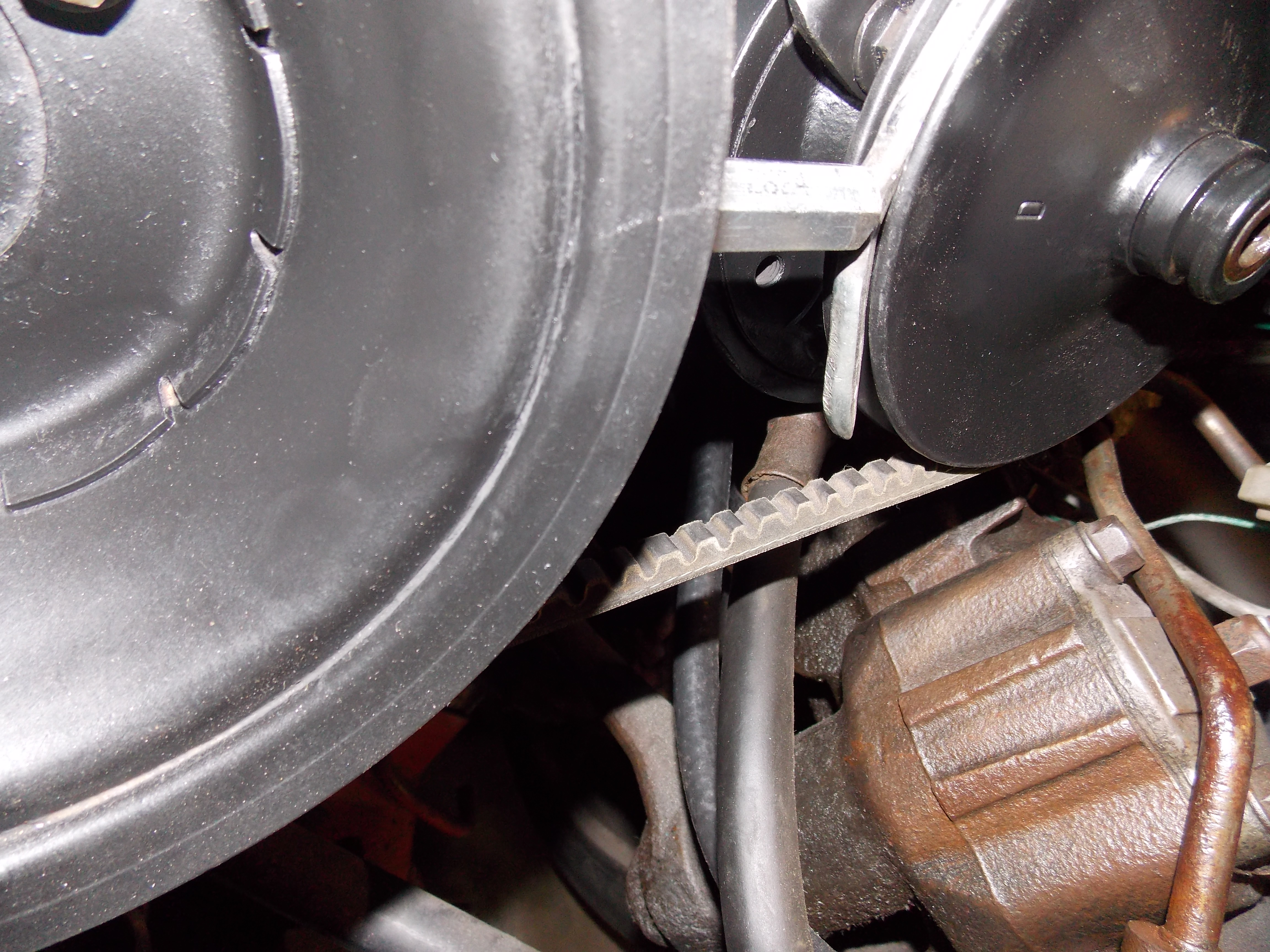

These three pictures show the tool in the completely collapsed or retracted state and set in place between the two pulleys. For those who suggested various tools, the distance between the pulleys at this point is only a little over 2.125 inches. Although the pictures do not show it, the ears of both of the saddles have had a taper ground into them to let them sit in the pulley grooves as deep as possible. At this point I had not as yet backed off the adjustment bolts for the pump. It was just sort of sitting in place with the bolts tight but the belt more or less loose. With the tool set in the crank pulley, backing off the pump bolts allowed the pump cradle to relax and the tool popped right into place. Backing the bolts off, strictly speaking, was not even necessary to set the tool into its location; just made it a little easier.

Without video, showing what happens next is sort of an imagination trip but, by using a standard 9/16ths combination wrench, the hex body can be unscrewed from the floating saddle and this pushes against the fixed saddle to move the pump out and away. When you get to a point where the belt tension is satisfactory or up to spec, you lock down the attaching bolt for the pump, starting with the one that attaches to the bracket that mounts to the exhaust manifold or header and, once they are tight and the belt tension works for you, collapse the tool by retracting the hex body and out it pops. End of story.

Coles Notes

The raw materials for this were two 3/8ths eye bolts and one 3/8ths hex coupling nut. The nut was given some love in my lathe to shorten it to size and bore the one end for the fixed saddle. The eyebolts were taken to the welding table, the cad plating sanded off, and the eyes welded shut where they returned to meet the body of the bolt. Hots of heat and plenty of wire for best penetration and extra meat to have on hand for subsequent shaping and twisting. To create the saddles, once the eyes had cooled down they were cut open again using a hack saw and then the ears or halves were spread apart until they were as flat as possible with a minimum amount of curve to match the curve of the pulley groove. With that degree of curve created and confirmed, they then had a taper ground into them so that they would sit in the pulley groove as deep as possible. This was a trial and error effort, grind a little, test the fit, grind some more. Although slow, I found the best tool for this was my trusty Dremel motor with a micro-grinding wheel fitted to it. The small size of the wheel let it get into tight curves and radiuses and is not as aggressive as larger motors meaning less chance of taking too much and having to go back to the welding bench.

Summarily, it worked. Moving on...……………………….

Nick

Once the tool is set in place