Just a thought, but if the glue doesn't work out I wonder if you could use a soldering gun to "plastic weld" it back together? In theory it should make it easier to melt and bond the plastic back together in a controlled manner.

Two-port Fuel Vapor Canister Recharge/Refurbish

- Thread starter 69hurstolds

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pics on the how much charcoal you are using ? I still have to buy all this stuff to re do my Canister

That thought did cross my mind, but the way they did it based on the plastic "weld" they did it seems like they used a plastic welder machine specifically designed for doing what they did. Regardless, I feel the soldering gun method MIGHT burn a hole in the thin canister plastic. It doesn't take much to melt it, even the dremel wheel needed the plastic dried snot removed periodically just from the heat it generated. It's a soft plastic with low melting point, which made me suspect a poly plastic, which doesn't like to be glued.Just a thought, but if the glue doesn't work out I wonder if you could use a soldering gun to "plastic weld" it back together? In theory it should make it easier to melt and bond the plastic back together in a controlled manner.

Thinking about it, I may use some black RTV adhesive anyway on the outside of the canister groove I made where the dremel cut just to fill that in. Might be able to shape it to fill in the potholes and do a neat enough job not to be noticed. It's down in the pocket anyway so what does show should be minimal, hopefully. Cutting at the seam resulted in being able to "snap" the bottom back into place but it will need additional holding power, obviously.

I'll get to that when the foam arrives. You're going to need at LEAST 20 oz. no matter which type you get. I bought 48 oz. of pellets. It will matter if you get the granules like GM used, or the pellets like I'm going to use. The pellets will obviously take up more space per unit weight, so it may not turn out the pellets would actually weigh 19.3 oz. (approximate) that came out of the canister to begin with. But I'll weigh out what goes in regardless.Pics on the how much charcoal you are using ? I still have to buy all this stuff to re do my Canister

It appears that GM used PLENTY of extra carbon to do what they needed to do as far as Federal Regulations required them to do back then. So using the pellets is my choice to minimize the leakage through any tiny cracks that may form in the foam retainer replacement.

Here's just ONE option for the granulated type:

But if you go to the local pet supply store, I'm sure you could find it in the aquarium filter section.

I used the formula (Pi) x radius x squared x height to assess cylinder volume. This is to add more useless information into the equation.

The unscientifically measured volume of the carbon chamber is 83.77 cubic inches. 4-15/16" diameter and effective height of 4-3/8". A little bit of this chamber is used for the two 1/4" thick foam retainers, but when compressed I doubt if they'd take up much room. I measured from the top of the canister frame to the bottom of the "ribs" on the insides of the canister where the top of the lower canister retainer frame insert rests before the bottom support ring would be put on.

I believe one key is to ensure the canister is full, but not packed over-full where it would try and force the carbon chunkies to try and push through the foam. This would be a bad situation and retainer failure would likely occur way sooner than designed.

The unscientifically measured volume of the carbon chamber is 83.77 cubic inches. 4-15/16" diameter and effective height of 4-3/8". A little bit of this chamber is used for the two 1/4" thick foam retainers, but when compressed I doubt if they'd take up much room. I measured from the top of the canister frame to the bottom of the "ribs" on the insides of the canister where the top of the lower canister retainer frame insert rests before the bottom support ring would be put on.

I believe one key is to ensure the canister is full, but not packed over-full where it would try and force the carbon chunkies to try and push through the foam. This would be a bad situation and retainer failure would likely occur way sooner than designed.

Wow. Just wow. Update like a mo -fo here.

My foam came in today. Yay! So I cut out a couple of pieces to the size needed. I also got the bright idea that I should buy some granulated carbon. While I don't think it matters that much, there's a reason GM used granulated over pelletized carbon. It could be because they got a deal on it, maybe simple as that. Or, it could affect canister performance. Thus, just to cover my base, I decided to buy this at Petsmart. I'm sure you could get it anywhere, but they happened to have it handy and for 15 bucks for 40 oz, I'm good with it.

So I learned something about densities, apparently. It SEEMS the pelletized carbon is more dense per unit of volume, thus it took the entire 3 lbs, 1 oz bag of net weight carbon pellets to fill the canister. Dayummm! I did that just to see what pellets would weigh to make the volume needed. I figured it'd be the other way around. Since I weighed the bag full (3 lbs, 1.7 oz) and then empty, I got a difference of 3 lbs, 1 oz., so it was net.

Then I weighed the 40 oz package of Top Fin granulated carbon. 2 lbs, 13 oz. gross (45 oz.). After filling the canister, I weighed what was left, twist tie, lid and everything. Got 15 oz. So that left 30 oz., or 1 lbs, 14 oz. of granulated carbon to fill the canister to the same level needed. That's like 2/3 the weight of the pellets!

This allows me to postulate that carbon from different sources, probably brands, and type (granules vs. pellets) weigh different amounts due to different densities. Which means you really can't go by a general rule of "it takes this much carbon" and say with any certainty what you'll need. So I'm putting brand and type here to let you know how much it took to fill the canister with enough carbon.

Again, here's the pelletized version I checked. 3 lbs, 1 oz. of this stuff will fill your 622 canister to where you need it. Comes in a 3 lb. bag. You'll need the whole bag.

With the foam going to deteriorate over time, I also hedged my bets on that too by buying some screen patch material. Like for your screen door? Yeah, that stuff. I cut two round discs to go in on the OUTSIDE of each foam retainer. This way the carbon can sit on the foam, and do it's thing like normal. But the screen will be a backup in case of foam failure over time. Probably well over my lifetime, but why not? I also have the plastic Loctite glue kit, so I'm going to see how that goes on gluing the bottom of the unit back together.

I did a low pressure air flow through both top ports of the canister. NO flow issues. I also dunked a sample of the foam retainer and screen into gasoline just to ensure it can hold up. Two hours soaking in gas and they were no use for wear. Hopefully all they'll see is vapor, but I'm confident they'll hold up.

Didn't get any pics of the stuff going together, but it's 1 screen goes in first, then the top foam retainer, the carbon fill, then the bottom foam retainer, and topped off by another screen disc. Then the gross plastic retainer disc can be slid into place. Then the bottom ring. The screens are there for nothing more than a last resort backup.

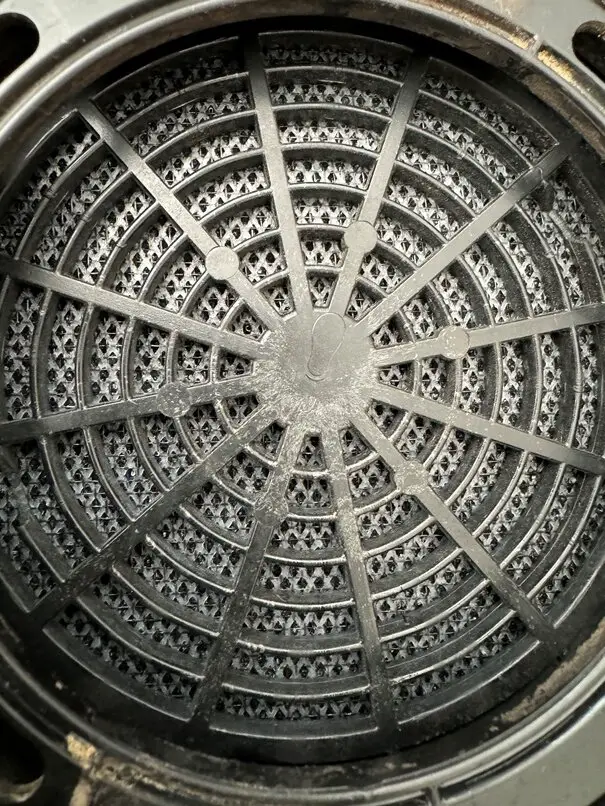

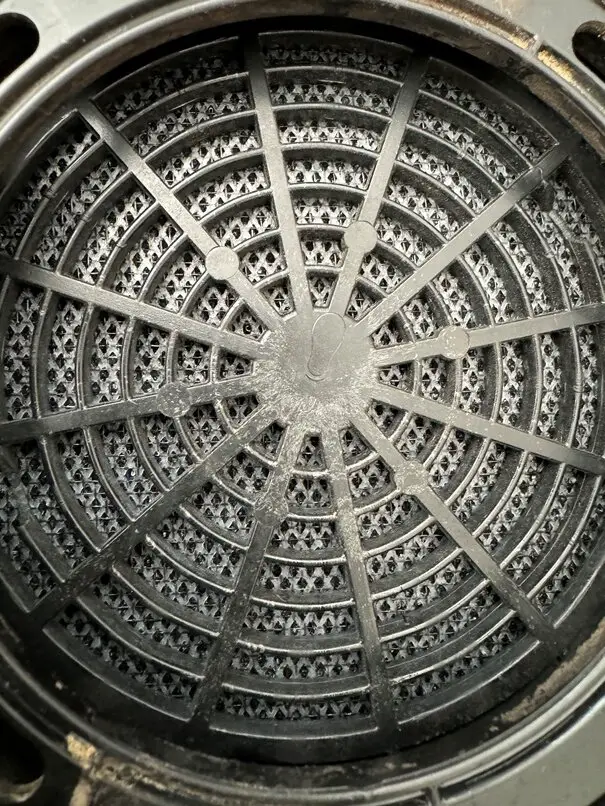

Test fit on the bottom ring. Will clean it up and then glue it in place and see what happens. You can see the screen here. No airflow restrictions will allow the canister to function properly again. More to follow.

My foam came in today. Yay! So I cut out a couple of pieces to the size needed. I also got the bright idea that I should buy some granulated carbon. While I don't think it matters that much, there's a reason GM used granulated over pelletized carbon. It could be because they got a deal on it, maybe simple as that. Or, it could affect canister performance. Thus, just to cover my base, I decided to buy this at Petsmart. I'm sure you could get it anywhere, but they happened to have it handy and for 15 bucks for 40 oz, I'm good with it.

So I learned something about densities, apparently. It SEEMS the pelletized carbon is more dense per unit of volume, thus it took the entire 3 lbs, 1 oz bag of net weight carbon pellets to fill the canister. Dayummm! I did that just to see what pellets would weigh to make the volume needed. I figured it'd be the other way around. Since I weighed the bag full (3 lbs, 1.7 oz) and then empty, I got a difference of 3 lbs, 1 oz., so it was net.

Then I weighed the 40 oz package of Top Fin granulated carbon. 2 lbs, 13 oz. gross (45 oz.). After filling the canister, I weighed what was left, twist tie, lid and everything. Got 15 oz. So that left 30 oz., or 1 lbs, 14 oz. of granulated carbon to fill the canister to the same level needed. That's like 2/3 the weight of the pellets!

This allows me to postulate that carbon from different sources, probably brands, and type (granules vs. pellets) weigh different amounts due to different densities. Which means you really can't go by a general rule of "it takes this much carbon" and say with any certainty what you'll need. So I'm putting brand and type here to let you know how much it took to fill the canister with enough carbon.

Again, here's the pelletized version I checked. 3 lbs, 1 oz. of this stuff will fill your 622 canister to where you need it. Comes in a 3 lb. bag. You'll need the whole bag.

With the foam going to deteriorate over time, I also hedged my bets on that too by buying some screen patch material. Like for your screen door? Yeah, that stuff. I cut two round discs to go in on the OUTSIDE of each foam retainer. This way the carbon can sit on the foam, and do it's thing like normal. But the screen will be a backup in case of foam failure over time. Probably well over my lifetime, but why not? I also have the plastic Loctite glue kit, so I'm going to see how that goes on gluing the bottom of the unit back together.

I did a low pressure air flow through both top ports of the canister. NO flow issues. I also dunked a sample of the foam retainer and screen into gasoline just to ensure it can hold up. Two hours soaking in gas and they were no use for wear. Hopefully all they'll see is vapor, but I'm confident they'll hold up.

Didn't get any pics of the stuff going together, but it's 1 screen goes in first, then the top foam retainer, the carbon fill, then the bottom foam retainer, and topped off by another screen disc. Then the gross plastic retainer disc can be slid into place. Then the bottom ring. The screens are there for nothing more than a last resort backup.

Test fit on the bottom ring. Will clean it up and then glue it in place and see what happens. You can see the screen here. No airflow restrictions will allow the canister to function properly again. More to follow.

've replaced the foams but never considered filleting the canister to replace the carbon purification medium. interesting.

Nick

Nick

You probably were just replacing the replaceable filter. To replace the foam retainers, you'd have to empty out the carbon bits. Maybe not the bottom one, but definitely need to empty it to replace the top one.'ve replaced the foams but never considered filleting the canister to replace the carbon purification medium. interesting.

Nick

Speaking of filters...

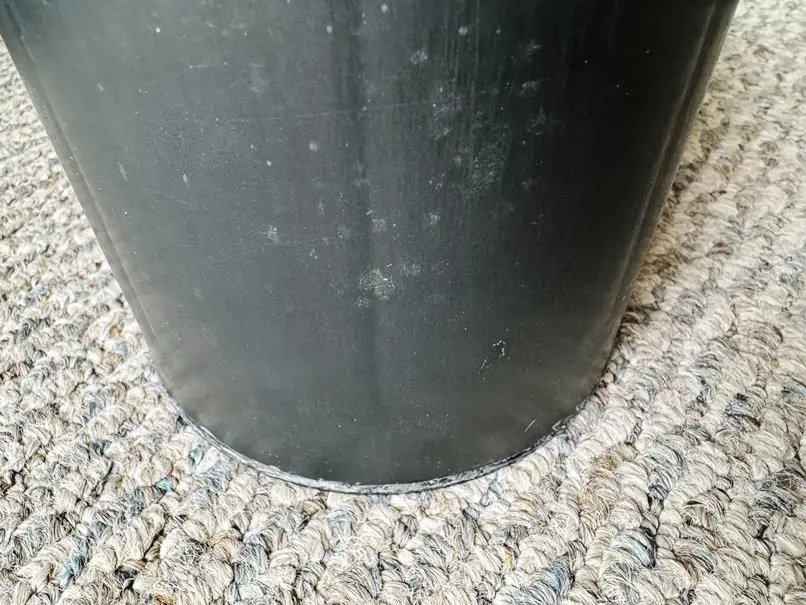

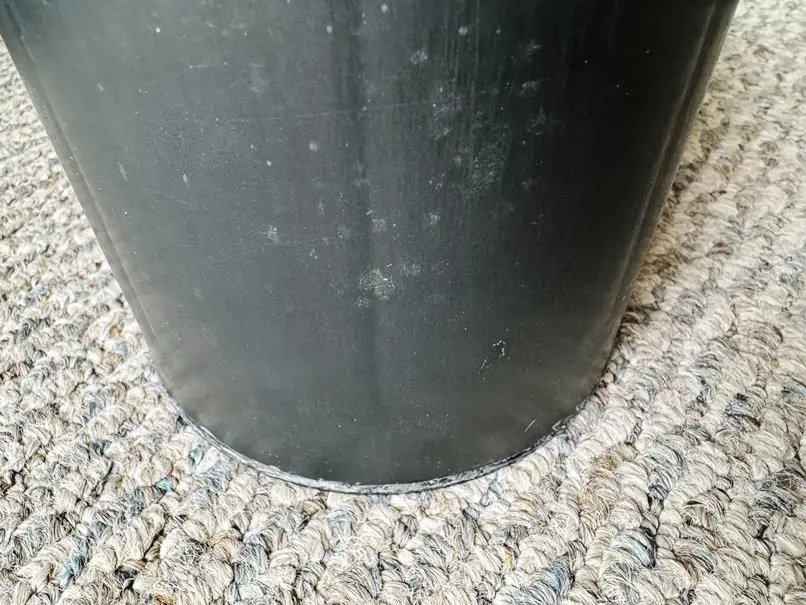

All done except for that ugly bottom seam and reinstall the clips and properly clock the clips. On the Cutlass, the clips align with the "front" of the vent tubes on top. In other words, looking at it from the top, place the vent tube openings straight up, then install the clips at 12 and 6 o'clock positions.

I used that loctite plastics glue kit where it has a primer and super glue in it. Use the primer on both areas of the contact points. Then use the glue on one piece, then assemble the parts. Sets up quick, then states full cure in 12-24 hours. It's already solid and I did a moderate pull and nothing moved. I believe this will work. I'm still not liking the botched surgical scars along the bottom perimeter, so I believe I'm going to get some of that black RTV adhesive. No fear on gasoline getting to it since it's on the outside of the can. I just don't like the way it looks. I'll try it with a mini-spatula to spread it into the crevice, but if it starts to look stupid I'll just live with it. It may not even be noticable in the little indentation it lives in anyway. We'll just have to see.

And that, as they say, is that. This canister should outlive me. Not that I HAD to do it, but now that I have, it's just one more thing to learn about.

All done except for that ugly bottom seam and reinstall the clips and properly clock the clips. On the Cutlass, the clips align with the "front" of the vent tubes on top. In other words, looking at it from the top, place the vent tube openings straight up, then install the clips at 12 and 6 o'clock positions.

I used that loctite plastics glue kit where it has a primer and super glue in it. Use the primer on both areas of the contact points. Then use the glue on one piece, then assemble the parts. Sets up quick, then states full cure in 12-24 hours. It's already solid and I did a moderate pull and nothing moved. I believe this will work. I'm still not liking the botched surgical scars along the bottom perimeter, so I believe I'm going to get some of that black RTV adhesive. No fear on gasoline getting to it since it's on the outside of the can. I just don't like the way it looks. I'll try it with a mini-spatula to spread it into the crevice, but if it starts to look stupid I'll just live with it. It may not even be noticable in the little indentation it lives in anyway. We'll just have to see.

And that, as they say, is that. This canister should outlive me. Not that I HAD to do it, but now that I have, it's just one more thing to learn about.

If anyone at home wants to attempt this, and needs any of the 1/4" foam retainer material, hit me up. I got plenty! 🙂

Similar threads

- Replies

- 5

- Views

- 188

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.