Two-port Fuel Vapor Canister Recharge/Refurbish

- Thread starter 69hurstolds

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which foam would this be?If anyone at home wants to attempt this, and needs any of the 1/4" foam retainer material, hit me up. I got plenty! 🙂

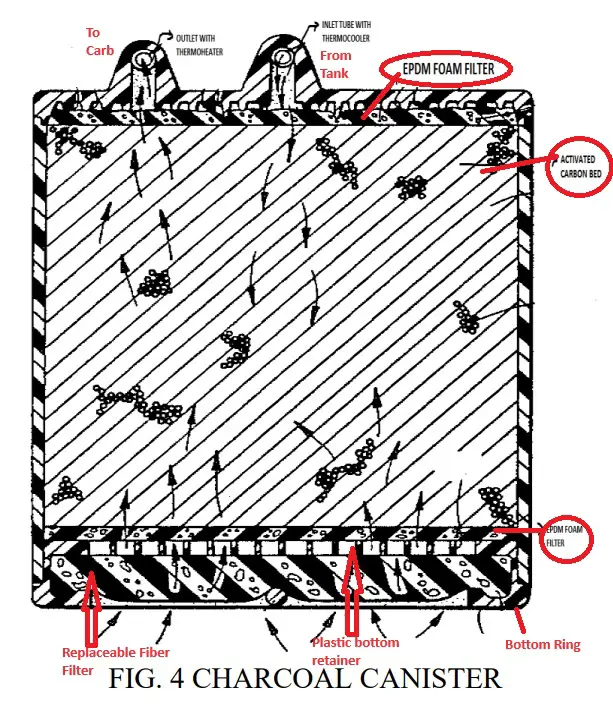

The foam under the plastic bottom and the top of the canister. The carbon sits between them. After the bottom is cut off, and everything is removed, the top foam goes in first, then the carbon, then the other foam, the push in plastic retainer, then you glue the bottom ring back on.Which foam would this be?

Here's the basic construction below. It's important to ensure that there is no slop in the canister carbon. In other words, the canister must be full enough to ensure the vapors are forced to vent into the carbon bed through the upper filter and not bypass the carbon at the top. If not enough carbon is added, that's exactly what it would do. It doesn't have to be crunched in there, but the foam is there to absorb any potential liquid fuel that makes it to the canister, condensed or otherwise. Believe it or not, the canister gains a little weight (milligrams) as the fuel vapors vent to it, and when the engine is started, those vapors get sucked back into the engine, reducing the weight again.

Yeah, that would be about right. Around here the bottom replaceable foam filters used to be available but not sure anymore if their part number is still good or defunct.

Nick

Nick

THANK YOU for the detailed descriptions of the canister job and the photos! I think for now, due to time limitations, I’ll only replace the bottom filter. I believe you said that the filter just pulls out? If so, what keeps it in place?Ok, I've decided to take my old canister out of the 85 442 and redo it. Not because it was bad, per se, but because if I screw it up, I got new ones stashed away so I've got a back-up plan. And since others have actually done this, it's something I've never done so it's on my "bucket" list of sorts.

Easy peasy to get it out. First, remove the 2 hoses that attach at the top nipples. Boom. Then, using a long extension and a 10mm socket, I used my electric ratchet to make quick work out of those little screws holding the canister down to the fenderwell. Lifts right out.

Then, clean the canister by wiping it down or whatever. It gets real dirty on the bottom, especially if you've never had it out before, like me.

View attachment 237360

Turn it over, find the replaceable filter. Just pinch it with your fingers and remove.

View attachment 237361

Here's where it sits.

View attachment 237362

Remove the clips with a small screwdriver or other tool.

View attachment 237363

Then inspect the bottom carbon bits retainer foam. Hmmm. This one looks like it was on its way out anyway. Note the cracks. Not good.

View attachment 237364

Now you can start trimming the little plastic bead left from the plastic "welding" done at the factory. This usually will leave you with a small seam area you can see. But it's nice and smooth around the bottom now.

View attachment 237365

The knife bit was getting tedious. I broke out my old battery powered Dremel. But wouldn't you know, the batteries were weak. I tried charging them like, forever, and they lasted for about 30 seconds after 3 hours on the charge.

View attachment 237366

Enough for today. I decided to disassemble the battery pack for the Dremel and found 6 of the 1.2V, 700mah AA NiCd batteries inside. Crap. Just happen to have some 1000 mah AA NiMH batteries for the wife's solar light thingies. Hmm.

So I spent the afternoon working on making a battery pack for the Dremel with the NiMH batteries. Just got it done and it works like a champ! But not going to rip into the canister this evening. I'll save that for another day. The wife just had some day surgery yesterday for a small procedure, so I've been bouncing back and forth taking care of her and trying to be quiet letting her rest. I got some carbon coming from the fish store, and I have a handful of canister replaceable filters on hand already, so we'll see what happens shortly.

More to follow...

Ok, I've decided to take my old canister out of the 85 442 and redo it. Not because it was bad, per se, but because if I screw it up, I got new ones stashed away so I've got a back-up plan. And since others have actually done this, it's something I've never done so it's on my "bucket" list of sorts.

Easy peasy to get it out. First, remove the 2 hoses that attach at the top nipples. Boom. Then, using a long extension and a 10mm socket, I used my electric ratchet to make quick work out of those little screws holding the canister down to the fenderwell. Lifts right out.

Then, clean the canister by wiping it down or whatever. It gets real dirty on the bottom, especially if you've never had it out before, like me.

View attachment 237360

Turn it over, find the replaceable filter. Just pinch it with your fingers and remove.

View attachment 237361

Here's where it sits.

View attachment 237362

Remove the clips with a small screwdriver or other tool.

View attachment 237363

Then inspect the bottom carbon bits retainer foam. Hmmm. This one looks like it was on its way out anyway. Note the cracks. Not good.

View attachment 237364

Now you can start trimming the little plastic bead left from the plastic "welding" done at the factory. This usually will leave you with a small seam area you can see. But it's nice and smooth around the bottom now.

View attachment 237365

The knife bit was getting tedious. I broke out my old battery powered Dremel. But wouldn't you know, the batteries were weak. I tried charging them like, forever, and they lasted for about 30 seconds after 3 hours on the charge.

View attachment 237366

Enough for today. I decided to disassemble the battery pack for the Dremel and found 6 of the 1.2V, 700mah AA NiCd batteries inside. Crap. Just happen to have some 1000 mah AA NiMH batteries for the wife's solar light thingies. Hmm.

So I spent the afternoon working on making a battery pack for the Dremel with the NiMH batteries. Just got it done and it works like a champ! But not going to rip into the canister this evening. I'll save that for another day. The wife just had some day surgery yesterday for a small procedure, so I've been bouncing back and forth taking care of her and trying to be quiet letting her rest. I got some carbon coming from the fish store, and I have a handful of canister replaceable filters on hand already, so we'll see what happens shortly.

More to follow...

THANK YOU for reposting your canister refurbishing job! Due to time limitations, I’ll replace the bottom filter for now. If I read your description right, you said it simply pulls out? What holds it in place, if anything? The photo on the left is the current filter, the right one is the one I got at a Napa store. Is this the correct filter?Ok, I've decided to take my old canister out of the 85 442 and redo it. Not because it was bad, per se, but because if I screw it up, I got new ones stashed away so I've got a back-up plan. And since others have actually done this, it's something I've never done so it's on my "bucket" list of sorts.

Easy peasy to get it out. First, remove the 2 hoses that attach at the top nipples. Boom. Then, using a long extension and a 10mm socket, I used my electric ratchet to make quick work out of those little screws holding the canister down to the fenderwell. Lifts right out.

Then, clean the canister by wiping it down or whatever. It gets real dirty on the bottom, especially if you've never had it out before, like me.

View attachment 237360

Turn it over, find the replaceable filter. Just pinch it with your fingers and remove.

View attachment 237361

Here's where it sits.

View attachment 237362

Remove the clips with a small screwdriver or other tool.

View attachment 237363

Then inspect the bottom carbon bits retainer foam. Hmmm. This one looks like it was on its way out anyway. Note the cracks. Not good.

View attachment 237364

Now you can start trimming the little plastic bead left from the plastic "welding" done at the factory. This usually will leave you with a small seam area you can see. But it's nice and smooth around the bottom now.

View attachment 237365

The knife bit was getting tedious. I broke out my old battery powered Dremel. But wouldn't you know, the batteries were weak. I tried charging them like, forever, and they lasted for about 30 seconds after 3 hours on the charge.

View attachment 237366

Enough for today. I decided to disassemble the battery pack for the Dremel and found 6 of the 1.2V, 700mah AA NiCd batteries inside. Crap. Just happen to have some 1000 mah AA NiMH batteries for the wife's solar light thingies. Hmm.

So I spent the afternoon working on making a battery pack for the Dremel with the NiMH batteries. Just got it done and it works like a champ! But not going to rip into the canister this evening. I'll save that for another day. The wife just had some day surgery yesterday for a small procedure, so I've been bouncing back and forth taking care of her and trying to be quiet letting her rest. I got some carbon coming from the fish store, and I have a handful of canister replaceable filters on hand already, so we'll see what happens shortly.

More to follow...

Attachments

Pull the old one out, and poke the new one in. It APPEARS to be the right filter, but the quarter doesn't give much of a reference. The filter is a friction fit underneath as you have to push it into place around the lip edge. You'll see when you yank the old one out.

Now, if carbon bits pour out, the canister retainer foam is toast, and you're likely going to have to replace the thing, or recharge it if you're crazy like a few of us.

Now, if carbon bits pour out, the canister retainer foam is toast, and you're likely going to have to replace the thing, or recharge it if you're crazy like a few of us.

The retainers or hold downs for the canister are two tabs, you can see one of them in IM6318 posted above. The canister sits in a pocket, possibly in the left side inner fender well, like mine does, and there are two threaded bosses, 180 degrees apart, into which a couple of 6-8 mm self tapping screwes get inserted, to hold the whole thing down.

Nick

Nick

Thank you!Pull the old one out, and poke the new one in. It APPEARS to be the right filter, but the quarter doesn't give much of a reference. The filter is a friction fit underneath as you have to push it into place around the lip edge. You'll see when you yank the old one out.

Now, if carbon bits pour out, the canister retainer foam is toast, and you're likely going to have to replace the thing, or recharge it if you're crazy like a few of us.

The filter just “fits” in there?!

Crazy! I’d think they’d have a way to lock it in, a retaining “cage” or similar. I’m concerned that the filter I got may not be the right size—I’ll measure it. I’m guessing that the carbon retainer foam is bad. Before I do anything to it, I’ll look around for a replacement canister. Doing the restoration of the canister will be more of a challenge than I want to deal with at this time.

Similar threads

- Replies

- 5

- Views

- 150

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.