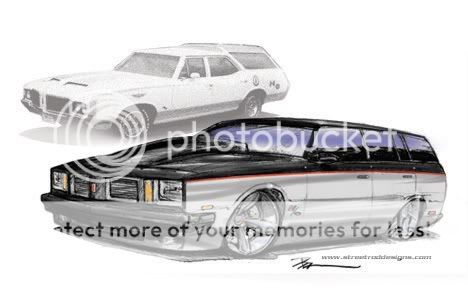

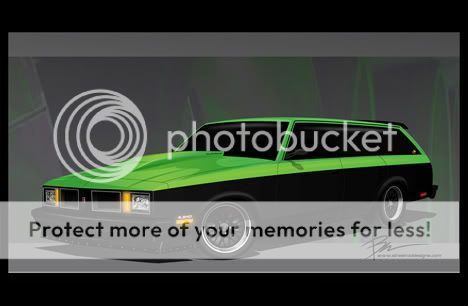

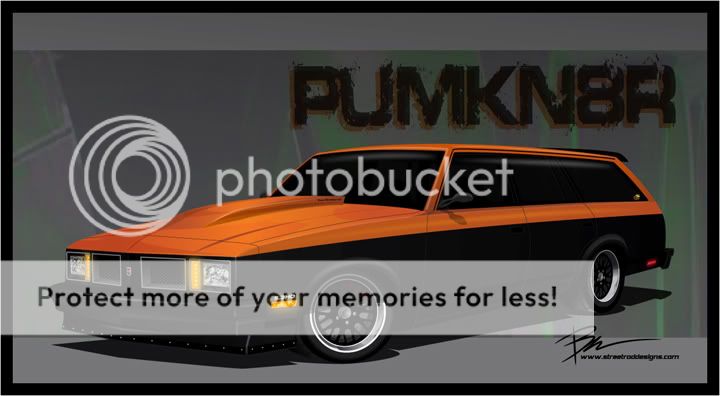

Hey guys, just wanted to start a thread of my project. Meet "The Pumkinator", my 1979 Olds Cutlass Cruiser that I picked up about 5 years ago. After a bit of tweaking and wrenching I've been daily driving it as my business hauler since that time, and decided recently it's time for a major overhaulin'. Hope you enjoy, as usual any comments/suggestions land on open ears...

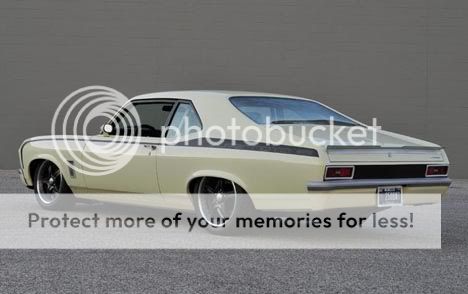

Here's the car right after purchasing.

Factory Options-

140 hp 305 Chevy V8

TH250

2.41 gears in the 7.5" rear

Rally gauge pack, no tach

Olds Rally wheels

Rear air deflector

Light Blue vinyl interior

8-track AM/FM stereo (still works!)

The car ran terrible, had absolutely no power despite the 305 had been rebuilt about 36,000 miles prior. The previous owner's wife bumping a truck in the snow sealed it's fate, and for $300 I drove it home.

First order of business after getting it home was pull out the G-tech. A whopping 21.79 @ 59 mph! The 0-60 time didn't even have a chance to register! 🤢

Checked the timing and found it WAAAAAAY retarded, in every sense of the word. Bumped it up and magically I felt some ponies again. Checked the carb and saw that the factory Q-jet's choke had been paper-clip wired open. Noticed in the process of doing that they blocked the secondaries from opening! Fixed that and with no other changes, the second G-tech run yielded an 18.67 at 74 mph. This is at 4500ft altitude up here in the Rockies, so I figured this was good enough to drive for the time being.

Fixed that and with no other changes, the second G-tech run yielded an 18.67 at 74 mph. This is at 4500ft altitude up here in the Rockies, so I figured this was good enough to drive for the time being.

Next on the list was new front end to pass our state's safety inspection. After a few days of searching I found a '78 Cutlass Cruiser in a farmer's field just a few miles from my place. Body was rusty, interior was hammered, but it had a transplanted Chevy 350/TH350 and a good front nose section. The guy told me they quit driving it because the trans was slipping. "How much you want for it?" I asked, "Oh... I'll take $75." Wasn't long before it was on a tow dolly on the way home. I Installed a battery and some gas in the carb and it fired right up! Ran o.k. but was clearly a high mile motor. Pulled and sold it, kept the trans as a core, and yanked the front clip and every other usable part off it before hauling it to the wrecking yard. Got a bunch of parts and made $300 cash off it, not a bad deal.

Here's the car right after purchasing.

Factory Options-

140 hp 305 Chevy V8

TH250

2.41 gears in the 7.5" rear

Rally gauge pack, no tach

Olds Rally wheels

Rear air deflector

Light Blue vinyl interior

8-track AM/FM stereo (still works!)

The car ran terrible, had absolutely no power despite the 305 had been rebuilt about 36,000 miles prior. The previous owner's wife bumping a truck in the snow sealed it's fate, and for $300 I drove it home.

First order of business after getting it home was pull out the G-tech. A whopping 21.79 @ 59 mph! The 0-60 time didn't even have a chance to register! 🤢

Checked the timing and found it WAAAAAAY retarded, in every sense of the word. Bumped it up and magically I felt some ponies again. Checked the carb and saw that the factory Q-jet's choke had been paper-clip wired open. Noticed in the process of doing that they blocked the secondaries from opening!

Fixed that and with no other changes, the second G-tech run yielded an 18.67 at 74 mph. This is at 4500ft altitude up here in the Rockies, so I figured this was good enough to drive for the time being.

Fixed that and with no other changes, the second G-tech run yielded an 18.67 at 74 mph. This is at 4500ft altitude up here in the Rockies, so I figured this was good enough to drive for the time being. Next on the list was new front end to pass our state's safety inspection. After a few days of searching I found a '78 Cutlass Cruiser in a farmer's field just a few miles from my place. Body was rusty, interior was hammered, but it had a transplanted Chevy 350/TH350 and a good front nose section. The guy told me they quit driving it because the trans was slipping. "How much you want for it?" I asked, "Oh... I'll take $75." Wasn't long before it was on a tow dolly on the way home. I Installed a battery and some gas in the carb and it fired right up! Ran o.k. but was clearly a high mile motor. Pulled and sold it, kept the trans as a core, and yanked the front clip and every other usable part off it before hauling it to the wrecking yard. Got a bunch of parts and made $300 cash off it, not a bad deal.