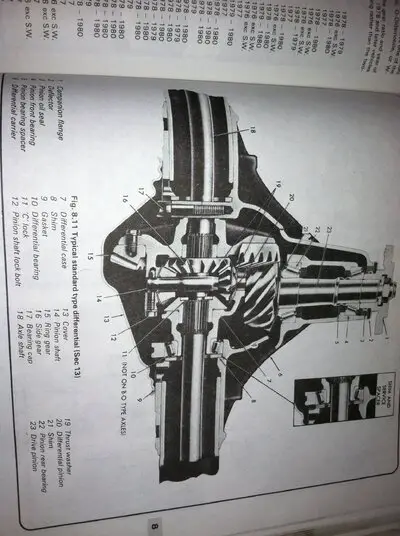

Bonnewagon said:Klaird, while it would seem possible to just change out the outer bearing and seal, what condition is the inside bearing? There are two you know, and both probably should be replaced. That said, the factory manual states that ANY part replacement requires rechecking everything to specs and using a new crush collar. But I would bet that you could get away with changing out BOTH bearings as well as the the races, reuse the stock inner bearing pinion shim (unless it's chewed up), a new crush collar, and reset the pre-load to "new bearing" specs. BUT, changing the bearing races is impossible without the pinion gear coming out, which requires the ring gear carrier to come out, which involves re-installing the stock cast carrier spacers (fragile- do not hammer them in) or a new carrier shim set. Ain't rears fun? But the original idea of just changing the outer bearing seems like the easy way out, but are you comfortable using a new bearing in an old race? Of course you could also just leave the bearings alone, tighten up the pinion nut to "used bearing" specs, add a new seal, and pray all will be well. Pinion pre-load is the inch pounds of torque needed to turn the pinion flange with NO brakes dragging. As you tighten the pinion nut to achieve pre-load, the collar crushes and too much ruins it, you can't loosen and try again, gotta replace it and start over. Do ya feel lucky?

you forgot to put the axles have to come out to remove the carrier...

but you are right, if the bearing in front needs to be replace the inner bearing would most likely be damaged as well since that one takes the direct force of the pinion trying to walk away from the crown.