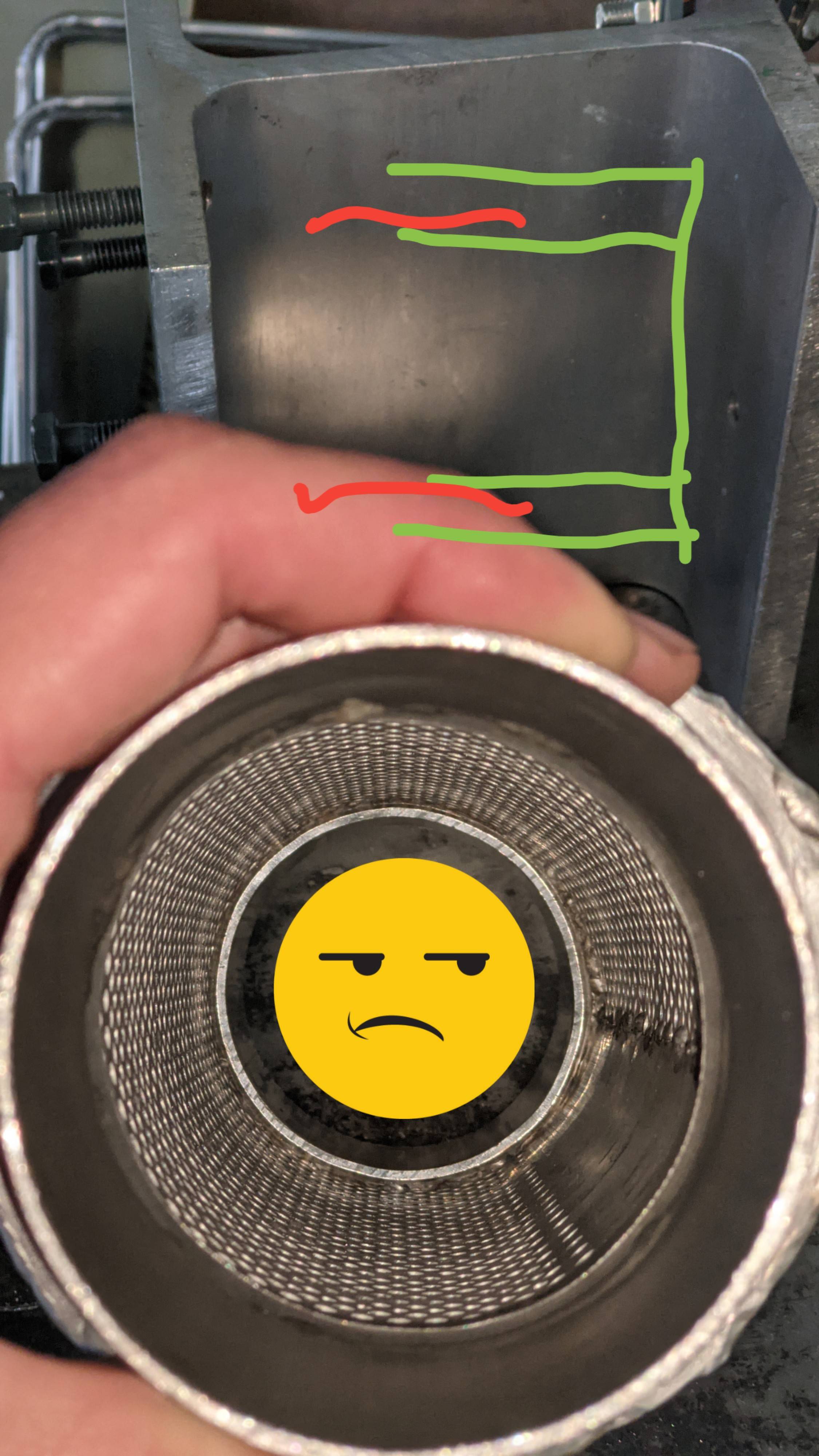

Welded? Yes. Well done? Not so much.

Happy Canada Day!

Happy Canada Day!

Meh..... The welds look like they'll hold & will work fine. How about well-done enough?

Welded? Yes. Well done? Not so much.

I commend you on a project most us mortals aren't equipped or have the skills to take on such a project. Imo you have a design flaw in your mufflers. Due to the amount of heat the inner muffler core will see vs the outside there will be different rates of expansion. In that style of muffler the inner core should float on either or both ends.

It's going under the car, it'll be fine.

I'm guessing you've already recorded finished weights for each unit?

I'm hopped up on meds and may be visualizing wrong.....Thanks. That's a pretty fair point. And it would have been easily to account for a month ago. Where the hell was this advice then?

I'm hopped up on meds and may be visualizing wrong.....

Isn't the inner pipe/core still visible/accessible from inside the pipe opening?

If so, couldn't a Dremel with a cutoff tool modify it being attached at both ends by curring from inside? Or am I just picturing the assembly wrong?

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.