I do NOT need to be emissions compliant. Th350 trans with a… 2800 stall… I think. Rear end is a 7.5 inch locker with 3.23 gears. The 350 had a Holley 650cfm with a HEI distributor. I plan on getting a bigger carb or even efi for new motor. I’d like to stay around the $6k-$7k mark, but I’ll spend the extra money if it means saving myself a headache in the future.

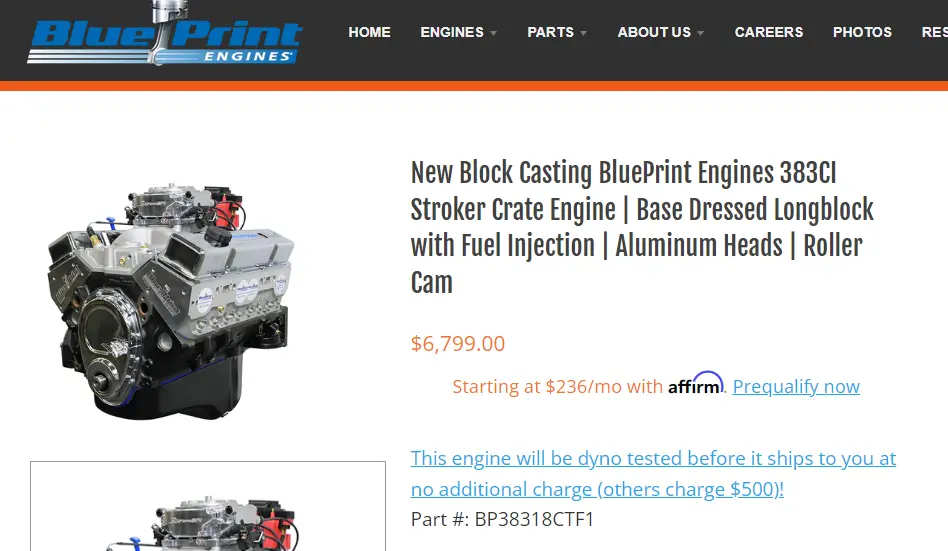

You really can not beat this deal right here already includes FI but would still need fuel pump and fuel lines.

I looked through your older posts and saw that your block is already bored over so even if you had a machine shop do some work for you I would guess you'd be .060 over so no room to rebuild in the future.

If you want to go forged bottom end they have a short block for $5000 plus youll need heads and everything else to complete it. (Heads, pushrods, rocker arms, valve covers, gaskets, ETC)

Not sure what block you have currently, but if its a 2 piece RMS without provisions for a roller cam you might want to take that into consideration as well.

Last bit of advice would be to go into a few good machine shops around you to find out what they would charge for machining and prepping your block along with balancing the rotating assy. Then compare that to the cost of a crate motor