)You bring up some good points Vern and I’d like to address them, NOT in anyway to get into a pissing contest but to see if you see any flaws in my reasoning.

I’m first to admit return system I’m building is overkill for almost any other place in the country. We have days on end of over 100 degrees, are at 4500 altitude and the fuel quality has gone down (and will probably continue to do so). I’m using this type of system based on some hard lessons I’ve learned over the years fighting vapor lock/heat soak problems in modifed cars. This particular system is a variation I have successfully run on a couple of cars over the years.

There are a couple of methods that can be used to prevent fuel from vapor locking (on a running car) or boiling in the line at engine shut off (heat soak). One is to increase the pressure of the fuel in the line . The other is to keep the fuel cool (fuel line routing and or keeping the fuel moving throughout the system to prevent it from absorbing heat). You can also run a combination of the 2, which sounds like the system you're using with an in tank pump and return line.

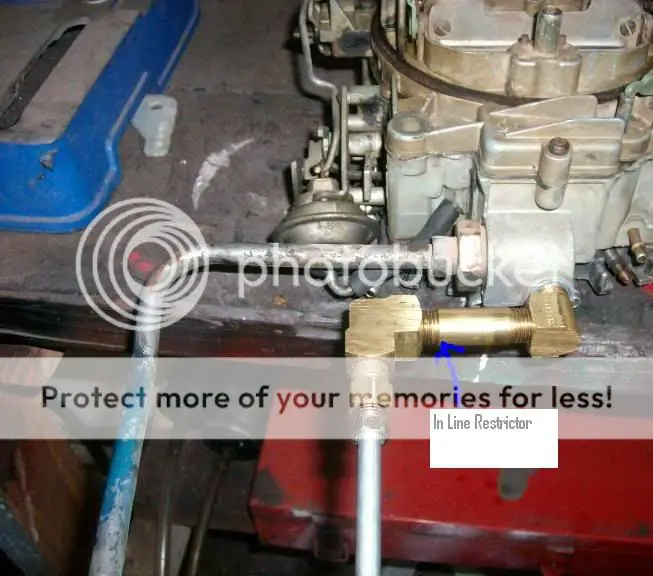

Picking the inlet of the carburetor as the transition point between the fuel supply side and return side rather than say using a fuel pump with a built in return line or a Chrysler type filter with provisions for a return line should insure cool fuel all the way to the carb rather than just to the pump or wherever the filter happens to be located.

I may not have been clear in my first post but his system is actually low pressure probably in the 4 ½-5 pound range at the needle (so I shouldn’t have any worries about over pressurizing the carb. The pump I’ll be using at the tank will be an external in line unit rated at 4-5 pounds and then what ever the stock style engine mounted pump produces. There are several reasons for the supply pump at the tank; it will help provide an adequate supply of fuel to the mechanical pump, it should help expel any hot fuel/and or vapor from the supply line to the return line prior to startup, it should also make it easier to start if I end up letting it sit for a couple of months without using it.

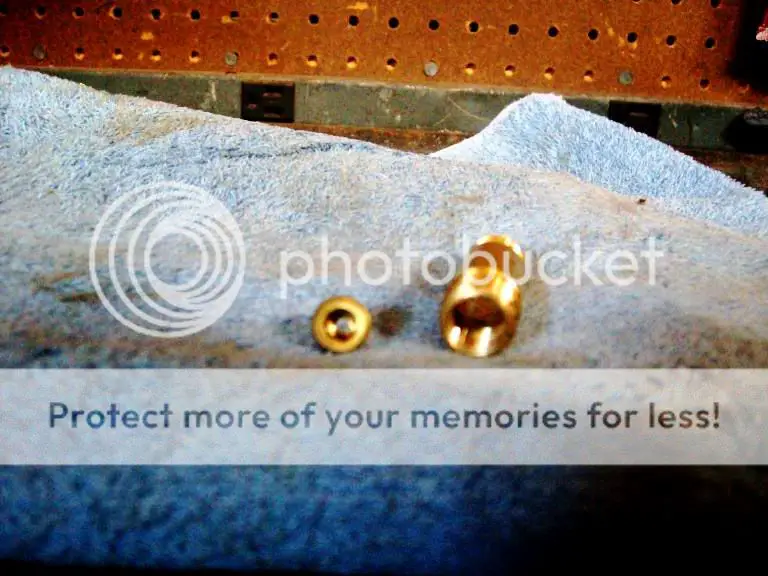

As far a regulating the fuel pressure at the carb, that is the purpose of the restrictor plug that screws into the pipe. The maximum pressure of the system will be determined by the stronger of the 2 fuel pumps (which in this case should be the mechanical pump on the engine and I’m guessing that will be in the 5-6 pound range). The size of the restrictor hole controls the amount of fuel bypassed and the pressure retained in the supply side of the system. The smaller the hole the less fuel is bypassed but the more pressure is retained at the carb. I have tried adjustable fuel regulators on the return line years ago but they proved to be troublesome and at this time I prefer a fixed restrictor. As I mentioned the 7/64” restrictor hole size is probably a starting point …..it’s not a size I pulled out of the air, it is the size of the restrictor I found worked best on the last system of this type I built. It should only drop the pressure by a little less than a pound but there are too many unknowns at this point to say for sure. Making a new restrictor of a different size only take a couple of minuets with plugs I already stock and about another 5 minuets to install.

As far as tank and fuel lines, I will be buying a new tank but as far as I know the El Camino tank is unique to the G Body’s as the fill tube is at the side instead of the rear. I like the idea of the redundant fuel pumps as that is one area that should never leave me walking home and if a pump does go out I don’t have to drop the tank to replace it I will be running a new 3/8” steel fuel line from the tank. I do have the benders and I usually buy the line in bulk rolls so I don’t have to do any slices. I know the stock senders only have a 5/16” line into the tank, but hopefully the electric pump at the tank will make up for that and prevent any starvation problems.

LOL On a side note, Once upon a time I got the brilliant idea to run a 1/2” aluminum fuel line on a street car out here turned out to be the worst vapor locking problems I ever had. Basically the real problem turned out to be that with a 1/2" column of fuel it was moving so slowly thru the system that it had a lot of time to pick up heat on its way to the carburetors.

This is definitely a function over form setup and I’m not real wild about the look of the bulky fittings. I am contemplating having the fittings powder coated either engine color or semi-gloss black to make them less noticeable but will see what happens when I get to that point.

By the way, I don't suppose you could show a picture of the electric choke setup on on your Q Jet. The original carb I have is still setup for the heat stove in the intake. You have me wondering if I can retro fit the electric choke from one of the spare Q Jets I have laying around.