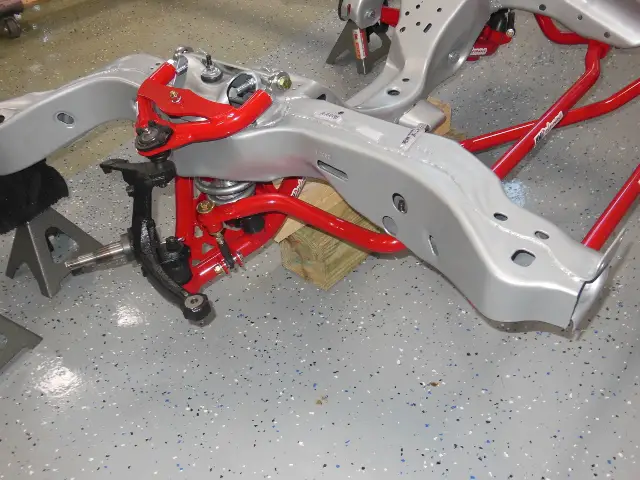

Well the powder coater didn't plug all the holes like he assured me he would. Does anyone know the best process to remove powder coat from threads ? I'm going to try and tap them with a carbine tip tap. I did get to mock up some of the UMI parts.

I've been wanting to know about those UMI bolt on rear trailing arm braces. I note in the photo you purchased them. Do you have any info on what benefit they may have over just leaving it stock? They are the one thing I cant seem to find feedback on.This past Monday a few friends and I took a trip up to Philipsburg Pa. To take a tour of UMI performance manufacturing plant. http://www.umiperformance.com/catalog/ and to pick up some goodies for the build (pix will follow). I had been corresponding with Ramey for a few weeks about suspension parts. He invited me up for a tour and had sent me a few videos of their Gbody Monte Carlo with one of their handling kits installed. You can check the clips out on youtube it's a green Monte, whipping through the cones at a high rate of speed and handling like a champ. While there we got to see every step of their manufacturing process from start to finish. From the set up of the jigs to the powder coating, it was amazing to see. Then he took us to the back to see some of their cars. I was disappointed the Monte wasn't there. He told us they had purchased an old race track and they had it at the track working on some new stuff. Then ask if we had time to go to the track. Um yes please! Just us three and two of their guys at the track. I'll see if I can figure out how to post some clips of the Monte. I have to say it was very reassuring to actually be able to see the parts I was purchasing being made and all the time, effort and care that went into them. I just wanted to share this with you guys, if you're looking for suspension parts, I honestly don't think you could go wrong with these guys. All the parts made right here in the USA. Maybe I should said I have no connection to UMI in any way shape or form, other than I bought their product and having seen it first hand. I believe it what they have to offer. Here's a few photos. I won't get my frame back from the powder coater's until next week. Or they would already be installed. 🙂

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.