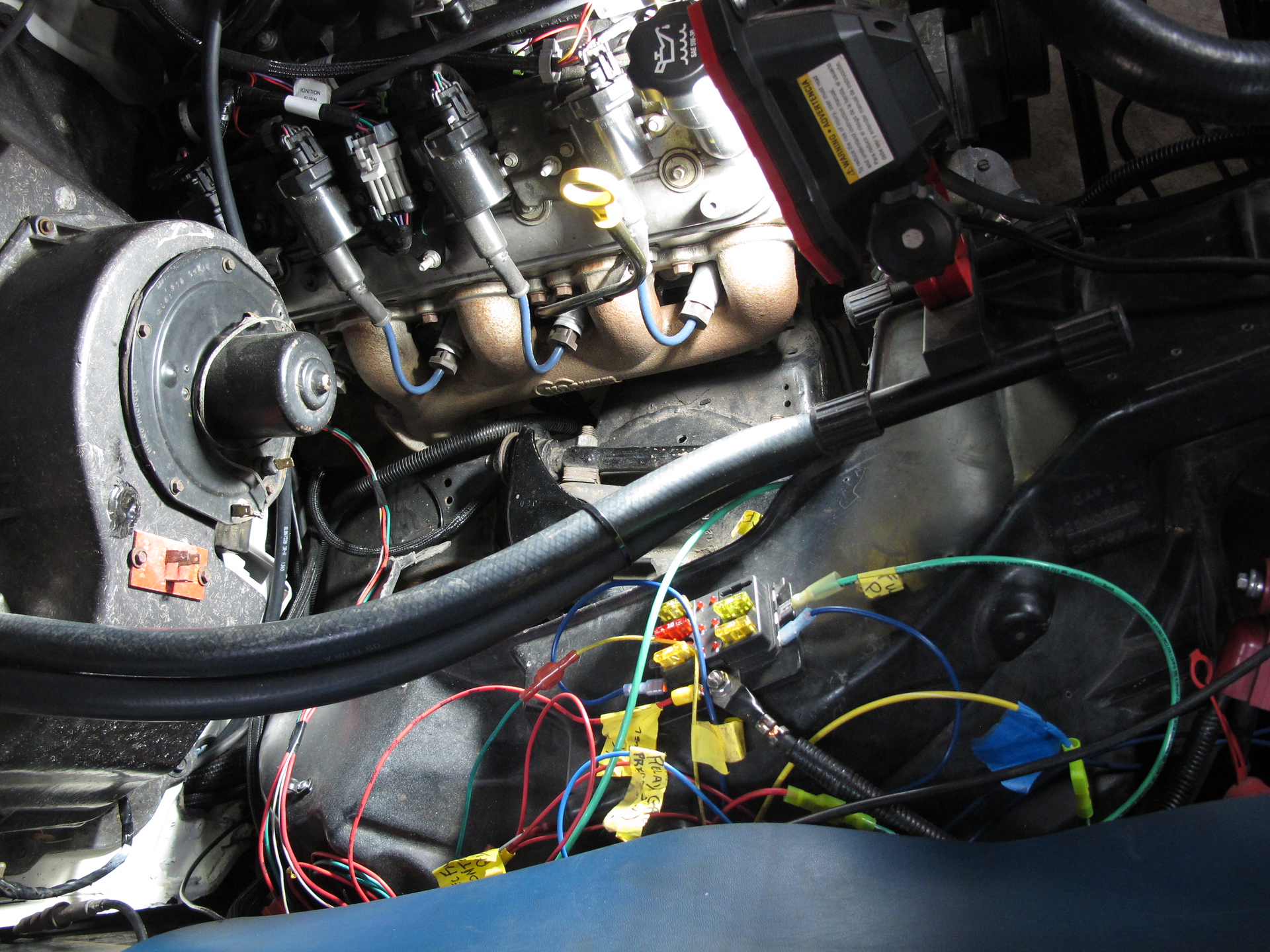

Advice about Holley, in case you aren’t aware, once you get this tuned after some reasonable amount of drive time - turn off the learn table via setting all of the values to 0%. I’ll explain if you ask, but you might know about this.

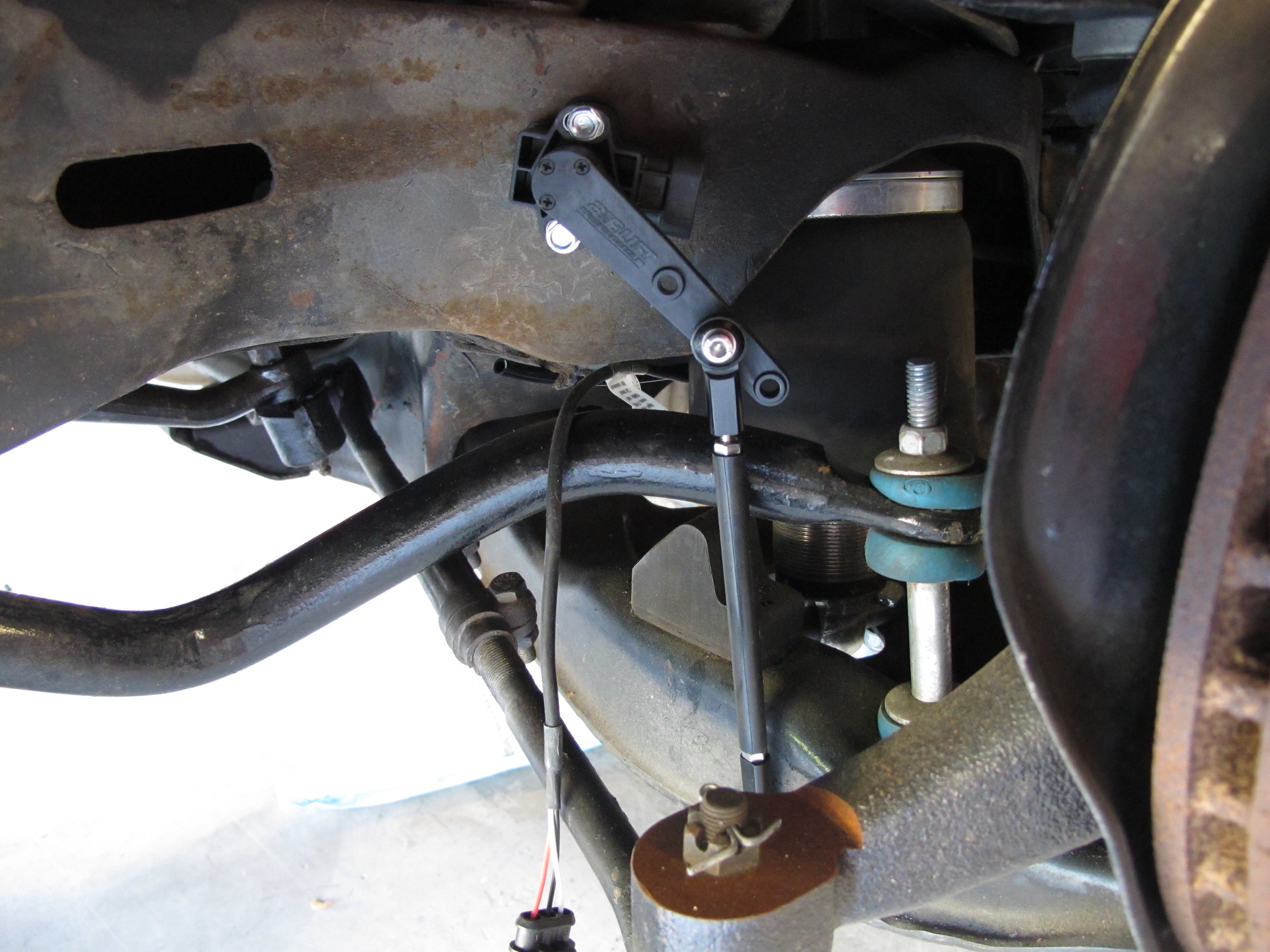

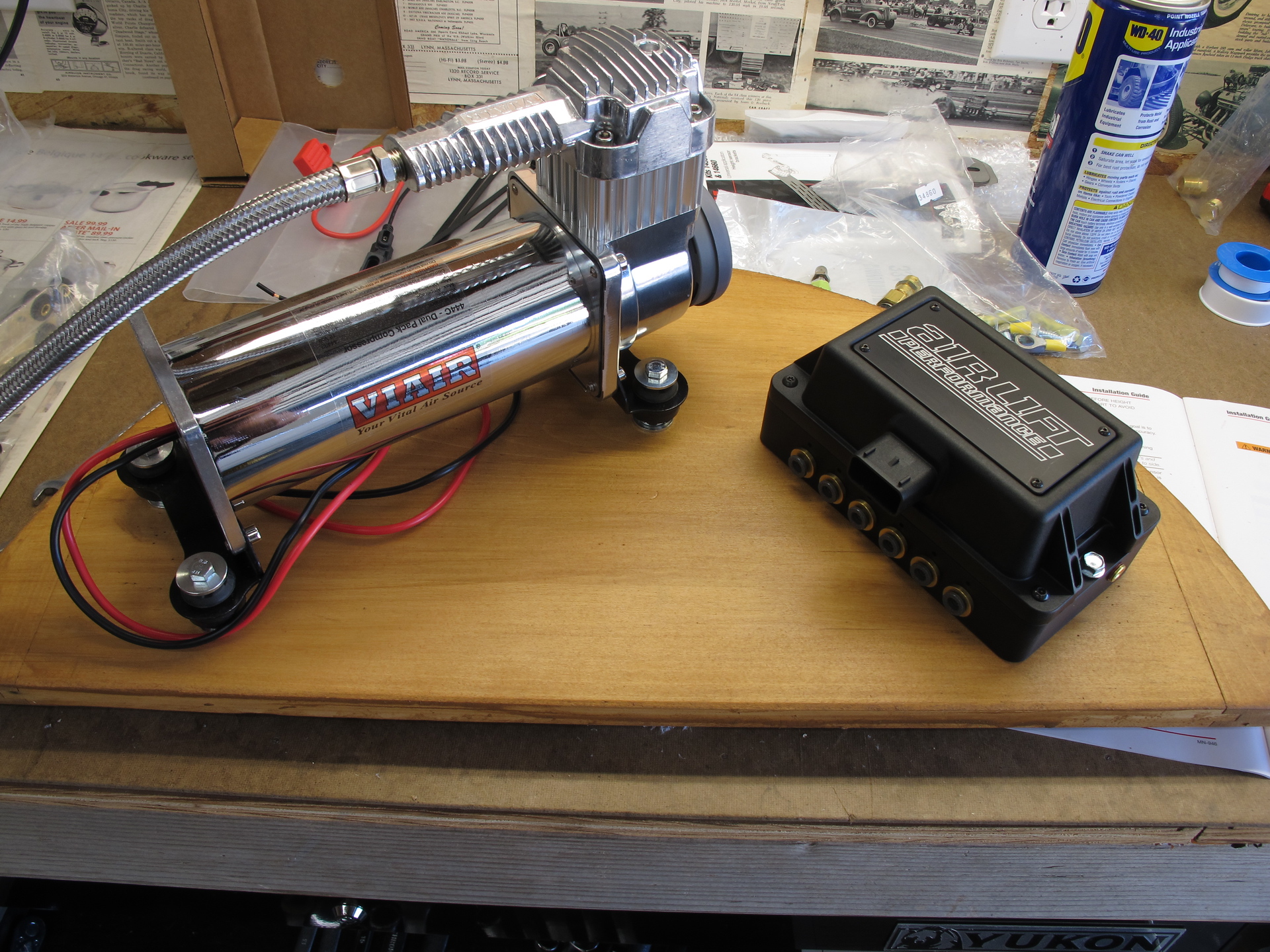

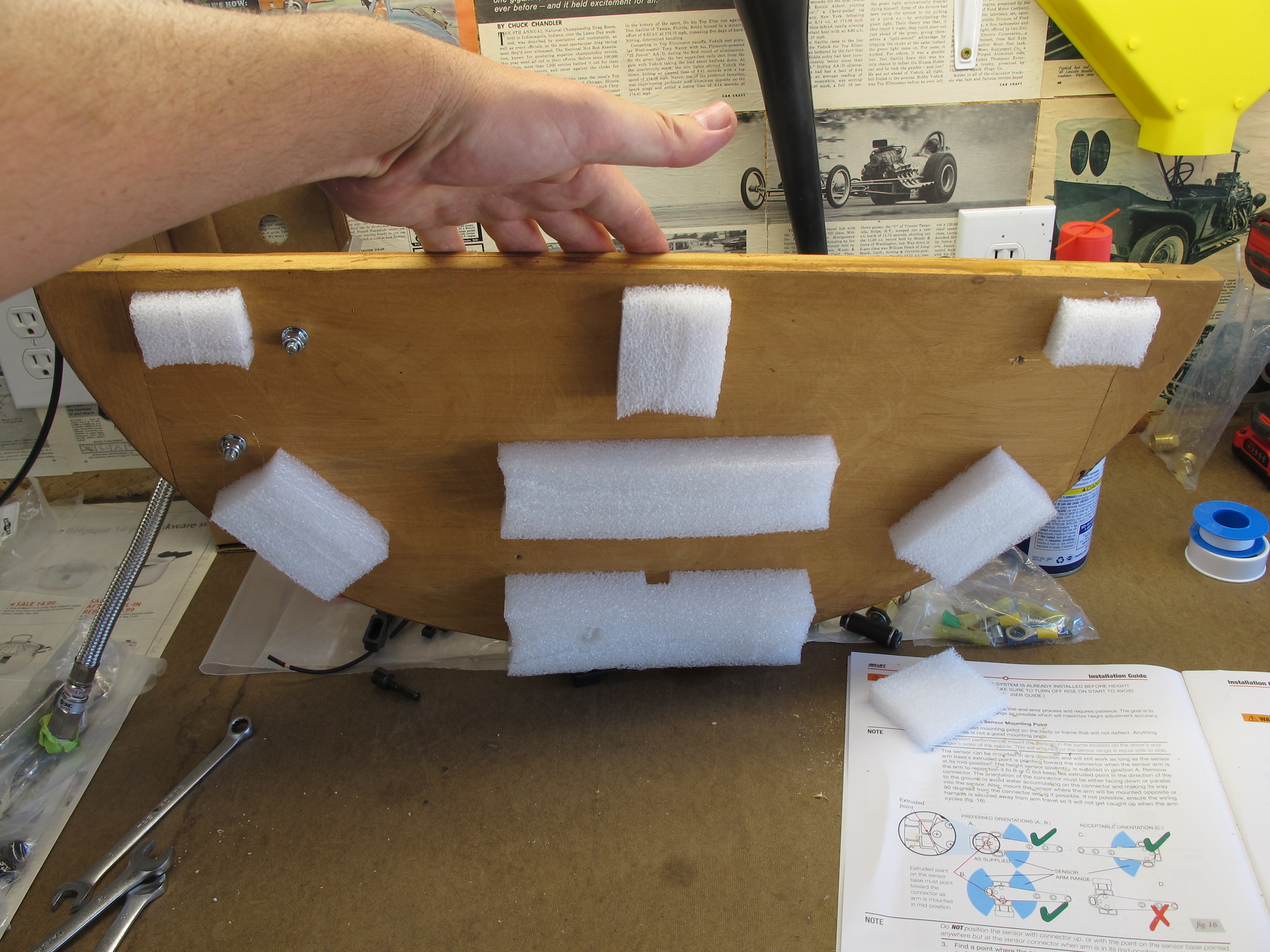

Regarding the air system and leaks over a couple of days, umm yeah, you’ll be living with that or have it chasing your tail forever with push lok fittings. There is a solution, but it has some unfriendly aspects.

I’d like to see the air system in use in person.

Regarding the air system and leaks over a couple of days, umm yeah, you’ll be living with that or have it chasing your tail forever with push lok fittings. There is a solution, but it has some unfriendly aspects.

I’d like to see the air system in use in person.