Putting some work in everyday! Not trying to rush to get things done, doing bunch of small projects at the same time. The brake drums were a quick and unexpected goal accomplished.

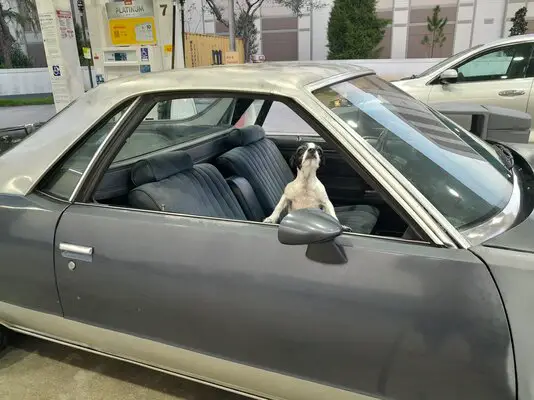

BUILD THREAD 84 El Camino build thread

- Thread starter SoFloG

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ac delete cowl drip rail installed, cleaned up some of the fan wiring and took her for a spin. Engine bay starting to come together

Attachments

Pleased enough with how the wheels came out and it was a good simple learning project for my son. Satisfied with the rims/tires now.

Attachments

Little update of randomness. Currently in the process of swapping the intake. It is taller than the summit intake but not by much everything looks like it will clear once bolted down with the drop base air cleaner. I haven't been running it anyways but nice to know I can for longer trips or dirt road outings.

Upon inspection of the distributor it appears to be really cheap and clunky, one of the lock washers holding the advance weights was magnetically stuck to the side of the control module which had one of the screws holding it on to the base of the distributor only half way tightened. Very sloppy cheap distributor with a 2016 production date... long story short I'm going to buy a new one. I've used chinesium hei dizzys before with success and haven't had one this crappy so I'll go that route again most likely.

The stock throttle/TV cable bracket doesn't fit and Im sure I could make some stand-off mounts but I don't want to mess around considering the importance of the TV cable and the 700r4. I've used cheap spectre brackets and adjustable oem ones from 2gc equipped cars with success, but with th350s and kick down cables or th400s without. I don't want to skimp.

Any suggestions for good brackets or mounting solution that will retain proper geometry with the high rise dual plane, Edelbrock carb, and oem throttle cable and 700r4 tv cable?

Upon inspection of the distributor it appears to be really cheap and clunky, one of the lock washers holding the advance weights was magnetically stuck to the side of the control module which had one of the screws holding it on to the base of the distributor only half way tightened. Very sloppy cheap distributor with a 2016 production date... long story short I'm going to buy a new one. I've used chinesium hei dizzys before with success and haven't had one this crappy so I'll go that route again most likely.

The stock throttle/TV cable bracket doesn't fit and Im sure I could make some stand-off mounts but I don't want to mess around considering the importance of the TV cable and the 700r4. I've used cheap spectre brackets and adjustable oem ones from 2gc equipped cars with success, but with th350s and kick down cables or th400s without. I don't want to skimp.

Any suggestions for good brackets or mounting solution that will retain proper geometry with the high rise dual plane, Edelbrock carb, and oem throttle cable and 700r4 tv cable?

Attachments

-

20231015_184740.jpg3 MB · Views: 63

20231015_184740.jpg3 MB · Views: 63 -

20231015_184802.jpg2.8 MB · Views: 68

20231015_184802.jpg2.8 MB · Views: 68 -

20231021_165642.jpg2.4 MB · Views: 64

20231021_165642.jpg2.4 MB · Views: 64 -

20231021_171205.jpg1.7 MB · Views: 65

20231021_171205.jpg1.7 MB · Views: 65 -

20231015_191639.jpg3 MB · Views: 68

20231015_191639.jpg3 MB · Views: 68 -

20231018_192104.jpg3.2 MB · Views: 69

20231018_192104.jpg3.2 MB · Views: 69 -

20231020_195937.jpg1.7 MB · Views: 62

20231020_195937.jpg1.7 MB · Views: 62 -

20231107_155526.jpg1 MB · Views: 60

20231107_155526.jpg1 MB · Views: 60 -

20231028_174958.jpg1.5 MB · Views: 61

20231028_174958.jpg1.5 MB · Views: 61 -

20231201_175751.jpg1.3 MB · Views: 62

20231201_175751.jpg1.3 MB · Views: 62 -

20231201_175321.jpg2.2 MB · Views: 70

20231201_175321.jpg2.2 MB · Views: 70 -

20231201_174432.jpg1.4 MB · Views: 59

20231201_174432.jpg1.4 MB · Views: 59 -

20231201_173714.jpg1.2 MB · Views: 62

20231201_173714.jpg1.2 MB · Views: 62 -

20231201_173706.jpg1 MB · Views: 57

20231201_173706.jpg1 MB · Views: 57 -

20231201_173700.jpg1.1 MB · Views: 62

20231201_173700.jpg1.1 MB · Views: 62 -

20231008_184201.jpg1.7 MB · Views: 67

20231008_184201.jpg1.7 MB · Views: 67

Last edited:

I've often wondered just how bad those Chinese HEIs are but never felt like trying one. I had a terrible experience with a Mallory Unilite and then bought an Accel and modified it, but I've read their quality has gone down- I don't know for certain. I think rebuilding a factory unit might be the cheapest and most reliable but buying a complete one is just so much easier.

As for the TV bracket, I've used the one from Holley with excellent results. You're right to not try and rig something as you can fry that transmission in 2 city blocks. I've done it (before I bought that bracket). I don't know that it will fit under a drop base though, because I paired it with a flat chrome base and 4" element. It has a tang to keep it from being able to spin on the mounting point but not all Eddy carbs have the relief for that tang. You can cut it off if you make sure the bolt can't come loose.

www.holley.com

www.holley.com

As for the TV bracket, I've used the one from Holley with excellent results. You're right to not try and rig something as you can fry that transmission in 2 city blocks. I've done it (before I bought that bracket). I don't know that it will fit under a drop base though, because I paired it with a flat chrome base and 4" element. It has a tang to keep it from being able to spin on the mounting point but not all Eddy carbs have the relief for that tang. You can cut it off if you make sure the bolt can't come loose.

Quick Fuel 49-95QFT Kickdown Cable Bracket for 700R-4 Transmissions

Quick Fuel Technology® announces the addition of several new carburetor accessories designed for a variety of applications.

Yea I've fried my share of 700r4s, and this is the best running one yet so I intend to keep it that way. The air cleaner is a luxury anyway. I'm going to check that bracket out, thanks.I've often wondered just how bad those Chinese HEIs are but never felt like trying one. I had a terrible experience with a Mallory Unilite and then bought an Accel and modified it, but I've read their quality has gone down- I don't know for certain. I think rebuilding a factory unit might be the cheapest and most reliable but buying a complete one is just so much easier.

As for the TV bracket, I've used the one from Holley with excellent results. You're right to not try and rig something as you can fry that transmission in 2 city blocks. I've done it (before I bought that bracket). I don't know that it will fit under a drop base though, because I paired it with a flat chrome base and 4" element. It has a tang to keep it from being able to spin on the mounting point but not all Eddy carbs have the relief for that tang. You can cut it off if you make sure the bolt can't come loose.

Quick Fuel 49-95QFT Kickdown Cable Bracket for 700R-4 Transmissions

Quick Fuel Technology® announces the addition of several new carburetor accessories designed for a variety of applications.www.holley.com

I also need to adresss the the crusted up deposits under the heat xover ports on the heads. It's nasty and I can't ignore it in good conscience especially since little pieces are already dropping in to the lifter valley. I'm going to plastic wrap the lifters and drain holes up tight and lay rags down and try to employ the shop vac with small attachment.

This engine is also "leaky" like most other 305's Ive had but not this bad! Oil was leaking up through the manifold bolts by the carb and the rear, leaking out of the rear gasket(which I never use for that reason), and the valve covers which I took care of.

I grabbed that bracket from a local Speed Shop cheaper than they were available online, so you might call around. Good idea on covering the valley and grabbing the Shop Vac.

I now use Teflon tape to seal the intake bolts after dealing with the oil creeping up and forming puddles on top. Some use silicone but I never, ever put that stuff into threaded holes, especially ones that could drop a piece into a drain hole or lifter and plug it up.

The Teflon tape will throw a torque reading off but if you need a torque wrench to correctly hit 25# we need to talk. I also much prefer 12 point bolts for everything on the outside of an engine not only for looks but for tool clearance. Using them on intakes works well, especially the 4 center bolts. They're great for headers although sometimes the small headed 6 point bolts with Allen head reliefs are required. And it always pays to buy "reusable" gaskets from Moroso, FelPro, Percy's, etc. whenever possible- I've never had one of those leak.

I now use Teflon tape to seal the intake bolts after dealing with the oil creeping up and forming puddles on top. Some use silicone but I never, ever put that stuff into threaded holes, especially ones that could drop a piece into a drain hole or lifter and plug it up.

The Teflon tape will throw a torque reading off but if you need a torque wrench to correctly hit 25# we need to talk. I also much prefer 12 point bolts for everything on the outside of an engine not only for looks but for tool clearance. Using them on intakes works well, especially the 4 center bolts. They're great for headers although sometimes the small headed 6 point bolts with Allen head reliefs are required. And it always pays to buy "reusable" gaskets from Moroso, FelPro, Percy's, etc. whenever possible- I've never had one of those leak.

I already use fel-pro for intake and head gaskets and ARP for anything going to the block. Hex head black bolts for the intake ordered and since random header bolts are falling out I ordered .75" ones with the tiny 5/16" hex heads. I prefer hex ARP stuff over 12 pt because the range of random garage tools that can be used since they're made in consideration already and the mobile tool kit doesn't have to be specialized. I have never use a tq wrench for an intake and only ever had one of dozens leak after my heavy equipment mechanic brother insisted on installing the rubber gaskets without my supervision lol. Ive never had the bolts leak either and don't use any kind of thread sealant. My son was pulling bolts and asked what the crap was all over the threads and clearly someone rtv'd them to still have them leak. That reminds me im going to have to chase those and make sure there aren't loose pieces floating around.I grabbed that bracket from a local Speed Shop cheaper than they were available online, so you might call around. Good idea on covering the valley and grabbing the Shop Vac.

I now use Teflon tape to seal the intake bolts after dealing with the oil creeping up and forming puddles on top. Some use silicone but I never, ever put that stuff into threaded holes, especially ones that could drop a piece into a drain hole or lifter and plug it up.

The Teflon tape will throw a torque reading off but if you need a torque wrench to correctly hit 25# we need to talk. I also much prefer 12 point bolts for everything on the outside of an engine not only for looks but for tool clearance. Using them on intakes works well, especially the 4 center bolts. They're great for headers although sometimes the small headed 6 point bolts with Allen head reliefs are required. And it always pays to buy "reusable" gaskets from Moroso, FelPro, Percy's, etc. whenever possible- I've never had one of those leak.

Last edited:

Similar threads

- Replies

- 3

- Views

- 307

- Replies

- 14

- Views

- 348

- Replies

- 3

- Views

- 166

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.