picked up the trans, popped it in, adjusted the new shifter, indexed the dipstick 1/4 inch above the machined surface, poured 2 gallons of dex 6 in for

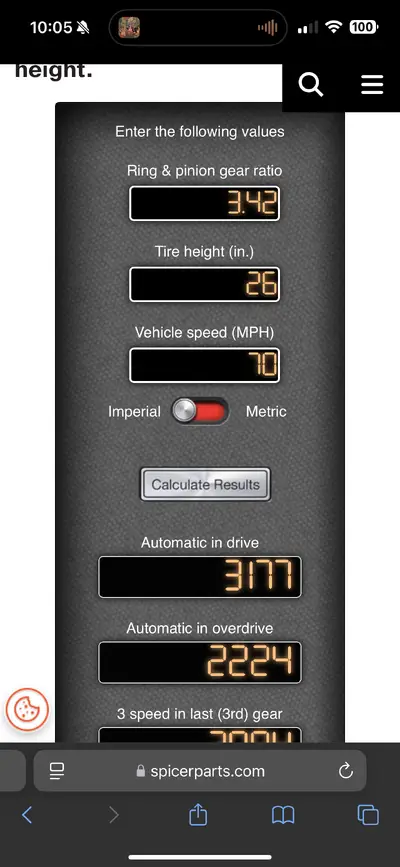

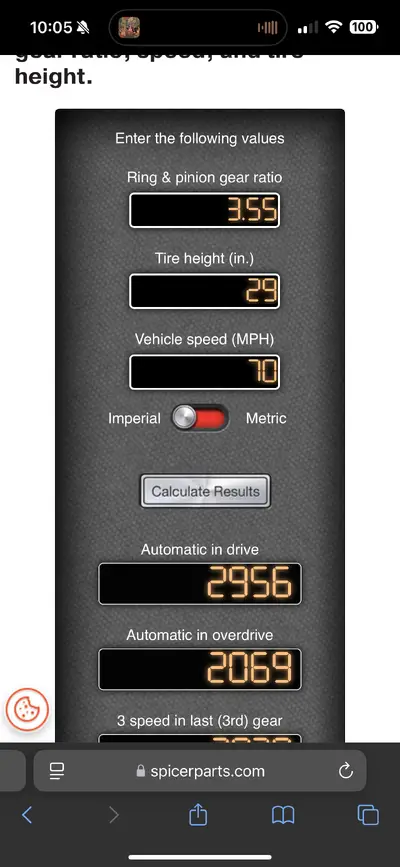

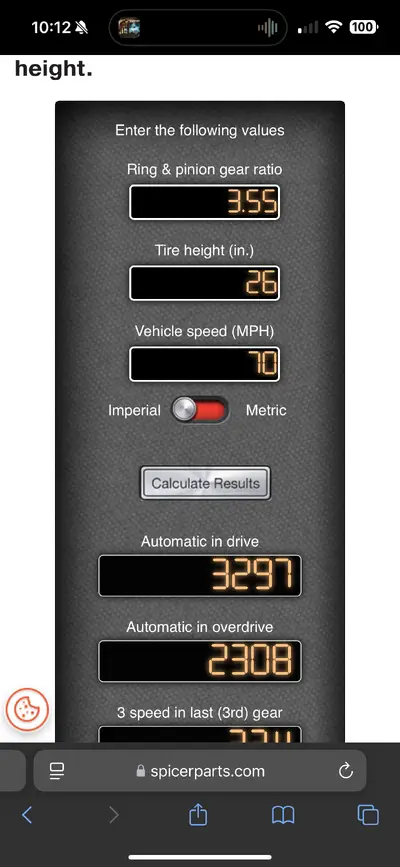

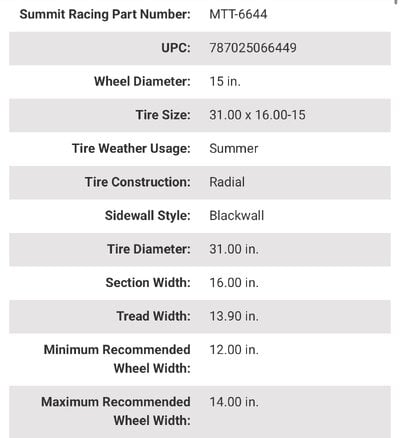

Now, going to wait to top it off when the diff is in and I can go through the gears, ran some heat shield wrapping on a few things, replaced the original cheap fuel cell cap, with a new cheap aluminum one lol atleast this one seals now, after reading for 3 hours of harnesses vs 3 point regular seatbelts and risks with cages/seats/4/5/6 point, I ended up ordering 2 sets of non retractable standard mount 3 point belts, since I’m using regular seats, and the main hoop is pretty far away from my noggin. and all is well, diff is getting done next month, getting a parts list together for it, order the Mickey Thompson sportsman’s 15x18x29s for the 14 inch weld knock offs around summertime and it should be good to go!

I may just wrap the car with gloss black vinyl eventually as well, the car is not worth the body work, but I don’t mind the 💩box look since I know what’s underneath it 😁

found driver side lower quarter panel, going to cut it out, weld, and fill it, I don’t think the company is a sponsor so I’ll refrain from mentioning the brand

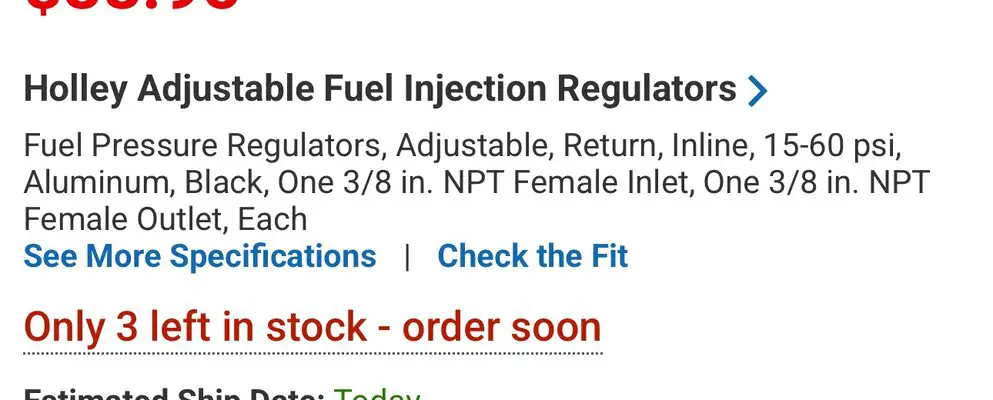

Ps I know the regulator should be 6 inches forward of the firewall, but for now that’s the most convenient spot for it 😆