I’ve got an 85 ss monte carlo. It’s hard to explain what my driver side door issue is but the driver side door on my Monte is very hard to close. To get it to fully close and seal you have to slam it. If you don’t it will latch but not go all the way in. It also feels as if there’s resistance when push the door towards the car. Especially when the door is right before closing. It’s there’s tension on the door. Like I should be able to let go of the door and it will swing to the car. But my door seems to get resistance/tension/tightness when I get close to closing it. Also not sure if this is normal but the passenger side feels super tight. When I open it it’s kinda hard to pull the door handle but when it goes it pops open pretty hard.

85ss Monte Carlo door issues

- Thread starter Irishspring46

- Start date

-

- Tags

- door door striker doorhinges

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

It’s got no movement. Weird..Have someone lift up the end of the door while it's open and then you can look for any movement within the hinge where the pin goes through in the middle and also where the roller is which should be centered on the pin it rides on.

If you can also post a picture or video of it

First thing we did was adjust the striker. It made it a tiny bit more smooth but you still have to slam it to close.if that's the case,try lowering the striker a little at a time that should help.

Do you know if the doors have been replaced? If the hinges don't have wear then you probably have to adjust to door by loosening it from the hinges.It’s got no movement. Weird..

Striker adjustment typically isn't needed and you want to get the body lines lined up with the door closing smoothly

Huh. And here I am, just removed, repaired, reskinned and replaced the complete driver's door assembly on my own 85 and about to do the same thing to the passenger's side.

First thing to know here is that your door is around 5 feet long and weighs as much as 70 lbs fully loaded. That weight is not symmetrical; that is it is not evenly distributed along the length of the door. if you have power windows, then the weight represented by the actuator assembly sits forward. Dismounting that door is not a one person exercise unless you have a door cradle. Think I posted pictures of mine awhile ago but I will be in the shop today taking some more pics of my passenger door which is on its way to being removed.

Monte doors have two hinges and those hinges have 6 metric bolts holding them in place, 3 for the door to the hinge, and 3 more from the hinge to the A Pillar. They are a hex head bolt and have an 11 mm head. if you plan to remove the door then the neat trick is to drill 1/8th holes through the hinge halves all the way into the A- pillar and the door hinge face, two per each hinge half, while they are still situated in their present location BEFORE you remove the bolts. Why? Because where they are is likely to be the default or factory position for the hinges when the car was assembled and that is your base alignment location. Once you take the door off the A-Pillar, if you have not made arrangements to mark its original location, then you are going to have a muy-mas miserable time trying to re-align that door in three distinct dimensions, vertically- up or down with respect to the door opening, back-forth to get the correct body gaps, and in/out, again to bring it into alignment with the body lines.

Tweaking the door latch pin is not a bad idea. They do wear and will show shininess where there has been metal to metal contact. They can also be shimmed out from the door jamb by adding a thin body washer that you will likely have to drill to get the right hole for the bolt. Those shims can also be found in the yards or at a Pick a Part if you like to go scavenging parts; door lock pins don't get picked all that often.

The suggestion about the gasket is not bad either. Both new gaskets and old gaskets that are torn or damaged can affect how easily the door will close.

The door I am currently dismantling was a slammer, like yours. Unless you put your whole body behind it and got some momentum, the odds were that it would hit the first catch and then bounce, meaning it was only half closed. When I looked at the bare shell, still hanging on it hinges yesterday, I happened to notice that the inner door shell appeared twisted, if you think of the door as a clock face then the 9-12 quadrant looked to be lying deeper into the door opening than the rest of the door.

If I had plans to address that, I would be looking at the hinge to door bolts for the upper hinge, with the thought that I would be pulling the door straight out from its present location. Here is the problem.

First, those top three bolts need to backed off just enough to get the barest of movement on the door shell. However, You can't just carefully and cautiously loosen off those top three bolts. by themselves. You also have to do the same to at least two of the bottom ones and only just take the tension off the third. WHY? because, if your door gaps and panel alignments are correct, then you want the door to come out or away from the opening in a straight line. Remember, you are dealing with a long heavy awkward lump of metal that is only being supported by 6 bolts and two pins. If you back those bolts too much then the door is going to DROP!

The other thing here is that, with the fender in place, you are going to be dealing with the hinge pins to get to those bolts. Don't use an open end wrench, They are tight and it will slip and you will have sacrificed a knuckle to the gods of pain for nothing.

I am back in the shop this PM to drop the passenger door on my own Monte and the plan was to take pictures. i will be posting a series of shots on this door, probably late today or this evening. they might give you a better idea of what you will be dealing with to do a door tweak.

Hopefully it is just the latch pin and you get to escape the hassle.

Nick

First thing to know here is that your door is around 5 feet long and weighs as much as 70 lbs fully loaded. That weight is not symmetrical; that is it is not evenly distributed along the length of the door. if you have power windows, then the weight represented by the actuator assembly sits forward. Dismounting that door is not a one person exercise unless you have a door cradle. Think I posted pictures of mine awhile ago but I will be in the shop today taking some more pics of my passenger door which is on its way to being removed.

Monte doors have two hinges and those hinges have 6 metric bolts holding them in place, 3 for the door to the hinge, and 3 more from the hinge to the A Pillar. They are a hex head bolt and have an 11 mm head. if you plan to remove the door then the neat trick is to drill 1/8th holes through the hinge halves all the way into the A- pillar and the door hinge face, two per each hinge half, while they are still situated in their present location BEFORE you remove the bolts. Why? Because where they are is likely to be the default or factory position for the hinges when the car was assembled and that is your base alignment location. Once you take the door off the A-Pillar, if you have not made arrangements to mark its original location, then you are going to have a muy-mas miserable time trying to re-align that door in three distinct dimensions, vertically- up or down with respect to the door opening, back-forth to get the correct body gaps, and in/out, again to bring it into alignment with the body lines.

Tweaking the door latch pin is not a bad idea. They do wear and will show shininess where there has been metal to metal contact. They can also be shimmed out from the door jamb by adding a thin body washer that you will likely have to drill to get the right hole for the bolt. Those shims can also be found in the yards or at a Pick a Part if you like to go scavenging parts; door lock pins don't get picked all that often.

The suggestion about the gasket is not bad either. Both new gaskets and old gaskets that are torn or damaged can affect how easily the door will close.

The door I am currently dismantling was a slammer, like yours. Unless you put your whole body behind it and got some momentum, the odds were that it would hit the first catch and then bounce, meaning it was only half closed. When I looked at the bare shell, still hanging on it hinges yesterday, I happened to notice that the inner door shell appeared twisted, if you think of the door as a clock face then the 9-12 quadrant looked to be lying deeper into the door opening than the rest of the door.

If I had plans to address that, I would be looking at the hinge to door bolts for the upper hinge, with the thought that I would be pulling the door straight out from its present location. Here is the problem.

First, those top three bolts need to backed off just enough to get the barest of movement on the door shell. However, You can't just carefully and cautiously loosen off those top three bolts. by themselves. You also have to do the same to at least two of the bottom ones and only just take the tension off the third. WHY? because, if your door gaps and panel alignments are correct, then you want the door to come out or away from the opening in a straight line. Remember, you are dealing with a long heavy awkward lump of metal that is only being supported by 6 bolts and two pins. If you back those bolts too much then the door is going to DROP!

The other thing here is that, with the fender in place, you are going to be dealing with the hinge pins to get to those bolts. Don't use an open end wrench, They are tight and it will slip and you will have sacrificed a knuckle to the gods of pain for nothing.

I am back in the shop this PM to drop the passenger door on my own Monte and the plan was to take pictures. i will be posting a series of shots on this door, probably late today or this evening. they might give you a better idea of what you will be dealing with to do a door tweak.

Hopefully it is just the latch pin and you get to escape the hassle.

Nick

Huh. And here I am, just removed, repaired, reskinned and replaced the complete driver's door assembly on my own 85 and about to do the same thing to the passenger's side.

First thing to know here is that your door is around 5 feet long and weighs as much as 70 lbs fully loaded. That weight is not symmetrical; that is it is not evenly distributed along the length of the door. if you have power windows, then the weight represented by the actuator assembly sits forward. Dismounting that door is not a one person exercise unless you have a door cradle. Think I posted pictures of mine awhile ago but I will be in the shop today taking some more pics of my passenger door which is on its way to being removed.

Monte doors have 6 metric bolts holding them in place, 3 for the door to the hinge, and 3 more from the hinge to the A Pillar. They are a hex head bolt and have an 11 mm head. if you plan to remove the door then the neat trick is to drill 1/8th holes through the hinge halves all the way into the A- pillar and the door hinge face, two per each half, while they are still situated in their present location BEFORE you remove the bolts. Why? Because where they are is likely to be the default or factory position for the hinges when the car was assembled and that is your base alignment location. Once you take the door off the A-Pillar, if you have not made arrangements to mark its original location, then you are going to have a muy-mas miserable time trying to re-align that door in three distinct dimensions, vertically- up or down with respect to the door opening, back-forth to get the correct body gaps, and in/out, again to bring it into alignment with the body lines.

Tweaking the door latch pin is not a bad idea. They do wear and will show shininess where there has been metal to metal contact. They can also be shimmed out from the door jamb by adding a thin body washer that you will likely have to drill to get the right hole for the bolt. They can be found in the yards or at a Pick a Part if you like to go scavenging parts; door lock pins don't get picked all that often.

The suggestion about the gasket is not bad either. Both new gaskets and old gaskets that are torn or damaged can affect how easily the door will close.

The door I am currently dismantling was a slammer, like yours. Unless you put your whole body behind it and got some momentum, the odds were that it would hit the first catch and then bounce, meaning it was only half closed. When I looked at the bare shell, still hanging on it hinges yesterday, I happened to notice that the inner door shell appeared twisted, if you think of the door as a clock face then the 9-12 quadrant looked to be lying deeper into the door opening than the rest of the door.

If I had plans to address that, I would be looking at the hinge to door bolts for the upper hinge, with the thought that I would be pulling the door straight out from its present location. Here is the problem.

First, those top three bolts need to backed off just enough to get the barest of movement on the door shell. However, You can't just carefully and cautiously loosen off those top three bolts. by themselves. You also have to do the same to at least two of the bottom ones and only just take the tension off the third. WHY? because, if your door gaps and panel alignments are correct, then you want the door to come out or away from the opening in a straight line. Remember, you are dealing with a long heavy awkward lump of metal that is only being supported by 6 bolts and two pins. If you back those bolts too much then the door is going to DROP!

The other thing here is that, with the fender in place, you are going to be dealing with the hinge pins to get to those bolts. Don't use an open end wrench, They are tight and it will slip and you will have sacrificed a knuckle to the gods of pain for nothing.

I am back in the shop this PM to drop the passenger door on my own Monte and the plan was to take pictures. i will be posting a series of shots on this door, probably late today or this evening. they might give you a better idea of what you will be dealing with to do a door tweak.

Hopefully it is just the latch pin and you get to escape the hassle.

Nick

First thing to know here is that your door is around 5 feet long and weighs as much as 70 lbs fully loaded. That weight is not symmetrical; that is it is not evenly distributed along the length of the door. if you have power windows, then the weight represented by the actuator assembly sits forward. Dismounting that door is not a one person exercise unless you have a door cradle. Think I posted pictures of mine awhile ago but I will be in the shop today taking some more pics of my passenger door which is on its way to being removed.

Monte doors have 6 metric bolts holding them in place, 3 for the door to the hinge, and 3 more from the hinge to the A Pillar. They are a hex head bolt and have an 11 mm head. if you plan to remove the door then the neat trick is to drill 1/8th holes through the hinge halves all the way into the A- pillar and the door hinge face, two per each half, while they are still situated in their present location BEFORE you remove the bolts. Why? Because where they are is likely to be the default or factory position for the hinges when the car was assembled and that is your base alignment location. Once you take the door off the A-Pillar, if you have not made arrangements to mark its original location, then you are going to have a muy-mas miserable time trying to re-align that door in three distinct dimensions, vertically- up or down with respect to the door opening, back-forth to get the correct body gaps, and in/out, again to bring it into alignment with the body lines.

Tweaking the door latch pin is not a bad idea. They do wear and will show shininess where there has been metal to metal contact. They can also be shimmed out from the door jamb by adding a thin body washer that you will likely have to drill to get the right hole for the bolt. They can be found in the yards or at a Pick a Part if you like to go scavenging parts; door lock pins don't get picked all that often.

The suggestion about the gasket is not bad either. Both new gaskets and old gaskets that are torn or damaged can affect how easily the door will close.

The door I am currently dismantling was a slammer, like yours. Unless you put your whole body behind it and got some momentum, the odds were that it would hit the first catch and then bounce, meaning it was only half closed. When I looked at the bare shell, still hanging on it hinges yesterday, I happened to notice that the inner door shell appeared twisted, if you think of the door as a clock face then the 9-12 quadrant looked to be lying deeper into the door opening than the rest of the door.

If I had plans to address that, I would be looking at the hinge to door bolts for the upper hinge, with the thought that I would be pulling the door straight out from its present location. Here is the problem.

First, those top three bolts need to backed off just enough to get the barest of movement on the door shell. However, You can't just carefully and cautiously loosen off those top three bolts. by themselves. You also have to do the same to at least two of the bottom ones and only just take the tension off the third. WHY? because, if your door gaps and panel alignments are correct, then you want the door to come out or away from the opening in a straight line. Remember, you are dealing with a long heavy awkward lump of metal that is only being supported by 6 bolts and two pins. If you back those bolts too much then the door is going to DROP!

The other thing here is that, with the fender in place, you are going to be dealing with the hinge pins to get to those bolts. Don't use an open end wrench, They are tight and it will slip and you will have sacrificed a knuckle to the gods of pain for nothing.

I am back in the shop this PM to drop the passenger door on my own Monte and the plan was to take pictures. i will be posting a series of shots on this door, probably late today or this evening. they might give you a better idea of what you will be dealing with to do a door tweak.

Hopefully it is just the latch pin and you get to escape the hassle.

Nick

And, like Ah-nee, I'm back.

So this is what the passenger side inner door shell of an 85 Monte Carlo SS looks like. The detail shot is the tape measurement of the physical width of the door, 58 inches or 2 inches shy of 5 feet.

The first picture in this sequence is a detail shot of the hinges, in this case, the top one which also carries the detent spring that works with the lever to hold the door in situ when open.

Because your door is both still intact and still hung on the A pillar, this is what you will be looking at if/when your need to adjust the door forces you to deal with the hinges. As you can see the bolt heads are semi buried behind the structure of the hinge. They can be got at using a 3/8ths power/johnson/breaker bar and a 6 pt 11mm shallow socket for the initial tug and then an 11mm gearwrench or similar. They will not only be tight but possibly rusted or glued in place by seam sealer if still factory undisturbed.

You mentioned the possibility that tweaking or slightly shifting the position of the latch striker pin might be your solution. In the first of these shots you can clearly see the shim that was placed in behind the striker pin. Adding shims like this has the effect of moving the pin away from the door jamb which puts it deeper into the latch mechanism. You might get away with one more shim but after that the head on the pin would likely crash into the back wall of the latch. i did mention fender washers as a basis for making a shim for this pin.

The second picture here is just of the T-50 torx socket that you will need to deal with the latch pin. Be sure that the torx head is buried square and completely into the pocket on the pin head or it can twist out, which can tear the "teeth" in the pin and lead to complications.

Remember when I mentioned that my inner door shell might be twisted? Well, judging from the apparent taper, the shell definitely isn't sitting square with respect to its location. Referencing back to the picture of all those hinge bolts, it would be the three upper hinge to door shell bolts noted in the one shot that would have to be slightly loosened and then the door pulled straight out to get the upper half of the door to move out or away from the door frame. As I also pointed out, the pivot point for the rotation that needs to be applied to this door would be at the lower hinge. In this case, of the three mounting bolts, it would be the pair of two that would be the loosest and the single bolt off to the side would be only loose enough to allow the door to move.

If the door was flush and lined up flat with with quarter panel but the door line did not match, then it would be the hinge to A pillar bolts that would be slightly loosened to allow you to pull straight up on the door to raise the latch end higher. Again, I have to point out that you are dealing with more than one dimension when you go to adjust a door. You may think that a quick pull on the door will lift it the amount you need, only to discover that while you got your lift, the door now sits either proud or sunken in its door frame. Truing a door is a walk away exercise: if you get frustrated, Walk Away, otherwise make sure that the wrench you end up throwing in frustration is a Harbor Freight Chinese cheapie and the direction you throw it in has nothing of value for it to hit and damage; people included.

For my own project, this is the replacement inner door skin or shell as I call it. These shots should give you some idea of the physical size of this part and the tale of the tape I posted above explains it all. What you are not seeing under its masking paper cover is the door side. it is not much different than the one in the first shot except it is a lot cleaner and has a fresh coat of grey interior rust preventative. Rust can germinate as much from moisture trapped inside the shell as it can from salt and crud eating away at the outside.

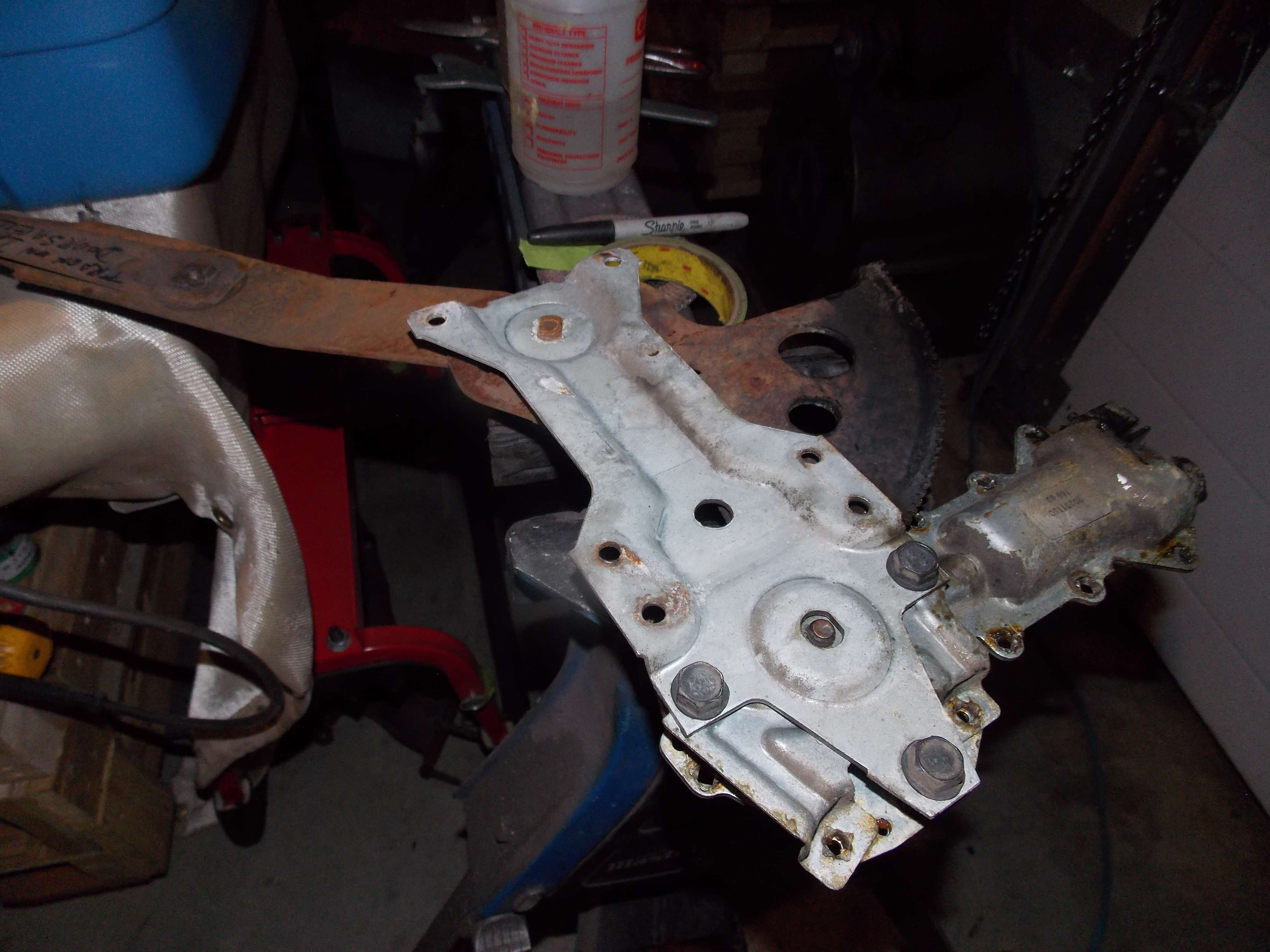

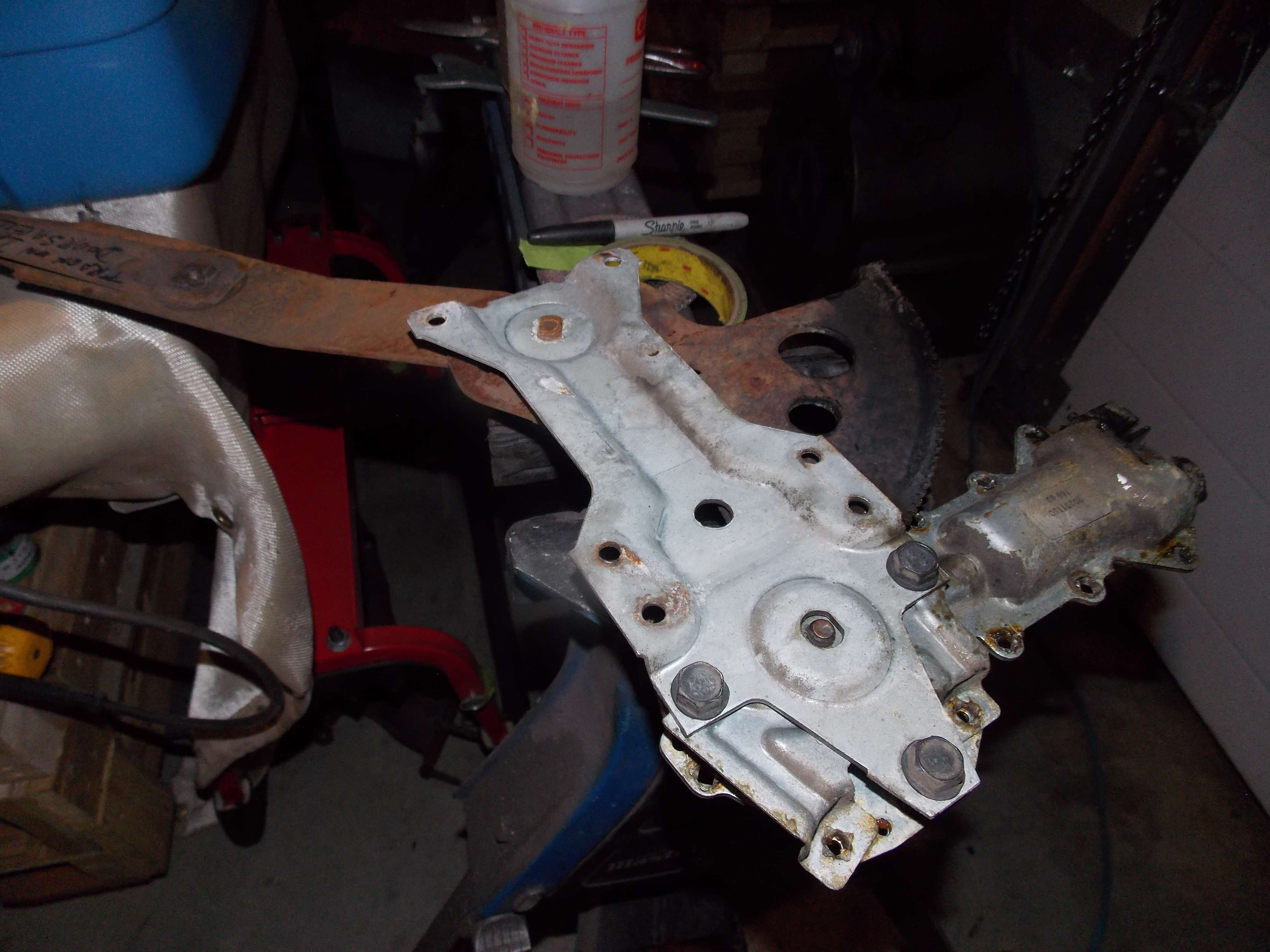

Finally, allow me to introduce you to one of the most dangerous components in a Monte Carlo. Physically it doesn't look like much but for the potential to maim and injure it is right up there with one of the front suspension coil springs!

This is the power window actuator. This one is upside down so what you see is the mounting flange and the motor drive. At the top, and mostly visible is the sector gear. if you were to flip this over you would see the reduction housing that holds both the drive gear and a viciously nasty preloaded coil spring. It is that spring that will cause the damage if, for whatever reason, the reduction housing breaks or gets damaged. Do NOT try to separate the motor from the drive section, that is guaranteed to hurt. If you have to deal with this unit, use a pair of vice grips to clamp the sector arm to the mounting frame so that even if things go horribly bad, the arm is pinned and frozen in place. Left free to move, you are dealing with the equivalent of a pair of king-sized scissors; and the damage they can inflict is about on a par with their size. How do I know? Ask me sometime.

So anyway, just a bit of what fits what for you to check out. Hope it helps.

Nick

So this is what the passenger side inner door shell of an 85 Monte Carlo SS looks like. The detail shot is the tape measurement of the physical width of the door, 58 inches or 2 inches shy of 5 feet.

The first picture in this sequence is a detail shot of the hinges, in this case, the top one which also carries the detent spring that works with the lever to hold the door in situ when open.

Because your door is both still intact and still hung on the A pillar, this is what you will be looking at if/when your need to adjust the door forces you to deal with the hinges. As you can see the bolt heads are semi buried behind the structure of the hinge. They can be got at using a 3/8ths power/johnson/breaker bar and a 6 pt 11mm shallow socket for the initial tug and then an 11mm gearwrench or similar. They will not only be tight but possibly rusted or glued in place by seam sealer if still factory undisturbed.

You mentioned the possibility that tweaking or slightly shifting the position of the latch striker pin might be your solution. In the first of these shots you can clearly see the shim that was placed in behind the striker pin. Adding shims like this has the effect of moving the pin away from the door jamb which puts it deeper into the latch mechanism. You might get away with one more shim but after that the head on the pin would likely crash into the back wall of the latch. i did mention fender washers as a basis for making a shim for this pin.

The second picture here is just of the T-50 torx socket that you will need to deal with the latch pin. Be sure that the torx head is buried square and completely into the pocket on the pin head or it can twist out, which can tear the "teeth" in the pin and lead to complications.

Remember when I mentioned that my inner door shell might be twisted? Well, judging from the apparent taper, the shell definitely isn't sitting square with respect to its location. Referencing back to the picture of all those hinge bolts, it would be the three upper hinge to door shell bolts noted in the one shot that would have to be slightly loosened and then the door pulled straight out to get the upper half of the door to move out or away from the door frame. As I also pointed out, the pivot point for the rotation that needs to be applied to this door would be at the lower hinge. In this case, of the three mounting bolts, it would be the pair of two that would be the loosest and the single bolt off to the side would be only loose enough to allow the door to move.

If the door was flush and lined up flat with with quarter panel but the door line did not match, then it would be the hinge to A pillar bolts that would be slightly loosened to allow you to pull straight up on the door to raise the latch end higher. Again, I have to point out that you are dealing with more than one dimension when you go to adjust a door. You may think that a quick pull on the door will lift it the amount you need, only to discover that while you got your lift, the door now sits either proud or sunken in its door frame. Truing a door is a walk away exercise: if you get frustrated, Walk Away, otherwise make sure that the wrench you end up throwing in frustration is a Harbor Freight Chinese cheapie and the direction you throw it in has nothing of value for it to hit and damage; people included.

For my own project, this is the replacement inner door skin or shell as I call it. These shots should give you some idea of the physical size of this part and the tale of the tape I posted above explains it all. What you are not seeing under its masking paper cover is the door side. it is not much different than the one in the first shot except it is a lot cleaner and has a fresh coat of grey interior rust preventative. Rust can germinate as much from moisture trapped inside the shell as it can from salt and crud eating away at the outside.

Finally, allow me to introduce you to one of the most dangerous components in a Monte Carlo. Physically it doesn't look like much but for the potential to maim and injure it is right up there with one of the front suspension coil springs!

This is the power window actuator. This one is upside down so what you see is the mounting flange and the motor drive. At the top, and mostly visible is the sector gear. if you were to flip this over you would see the reduction housing that holds both the drive gear and a viciously nasty preloaded coil spring. It is that spring that will cause the damage if, for whatever reason, the reduction housing breaks or gets damaged. Do NOT try to separate the motor from the drive section, that is guaranteed to hurt. If you have to deal with this unit, use a pair of vice grips to clamp the sector arm to the mounting frame so that even if things go horribly bad, the arm is pinned and frozen in place. Left free to move, you are dealing with the equivalent of a pair of king-sized scissors; and the damage they can inflict is about on a par with their size. How do I know? Ask me sometime.

So anyway, just a bit of what fits what for you to check out. Hope it helps.

Nick

Before you loosen any hinges from their position, look to see if the hinge pin bushings are cracked or missing all together. If the hinges look like they've never been moved or removed, then I wouldn't loosen them or move them until all else fails. If they're on in the position they were when made then something else is causing the issue. Check the pins and bushings with your calibrated eye balls and make sure they're in good shape. If they're OK, then maybe take the striker off all together and check the movement of the door while closing and how it lines up with the fender and quarter when closed. If it's off, then maybe it had a love tap in its past that moved the body out of shape.

Start at the hinges and work out from there. If you loosen the hinges without physically checking everything else first, you may chase the wrong problem.

Hutch

Start at the hinges and work out from there. If you loosen the hinges without physically checking everything else first, you may chase the wrong problem.

Hutch

when I'm hanging/fitting a door ill usually remove the striker altogether that way it doesn't dictate where it goes and I'll have an idea what I'm working with.after the lines are true then ill reinstall the striker.these guys are rite about the hinges being fairly problematic as these doors are hefty and over time they wear

If the roller that rides the detent lever is worn or flopping around on its pin, then it is time to find a yard that has a hulk that still has its door hinges hanging off the A pillar. Those roller pins are not rebuildable and not offered as a repair part. OPGI offers hinge assemblies as repro kits. The actual pins and bushings are also available as kits from Dorman among others. If the bushing is the culprit and has been wallowed out for a while, then you may find that you will have to oversize the hole into which the bushing gets pushed and stuff in the largest bushing provided. While the ID of this component remains stock, it is the outer or OD that is much larger as it usually takes some serious drilling to get the receiving hole back to round and square. That same OD is also serrated or toothed to lock it into place when it is installed. Pictures??? Yeah............ possibly..................................

Nick

Nick

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 185

- Replies

- 16

- Views

- 300

- Replies

- 0

- Views

- 91

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.