I think my cam is .600+ lift. I don't know at what lift BTR believes that the vavle springs need to be changed every year, but mine is one step down from that.I wonder if you have the same cam I do- BTR on a Comp coreView attachment 164598

BBO 496ci serpentine convertion W/ dyno sheet

- Thread starter Extreme Supreme

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Gotcha. I was just trying to guess how much steam my 468 is making.I think my cam is .600+ lift. I don't know at what lift BTR believes that the vavle springs need to be changed every year, but mine is one step down from that.

How much did those heads set you back?

Can't recall the exact number, we did some horse tradin for the cnc time for the port work. I wrote the program to cut the offset push rod holes for his CNC 5 axis mill. I'd love to get the heads flowed one day. I spent a lot of time on the short turn radius and opening the "throat" below the vavle seats.Gotcha. I was just trying to guess how much steam my 468 is making.

How much did those heads set you back?

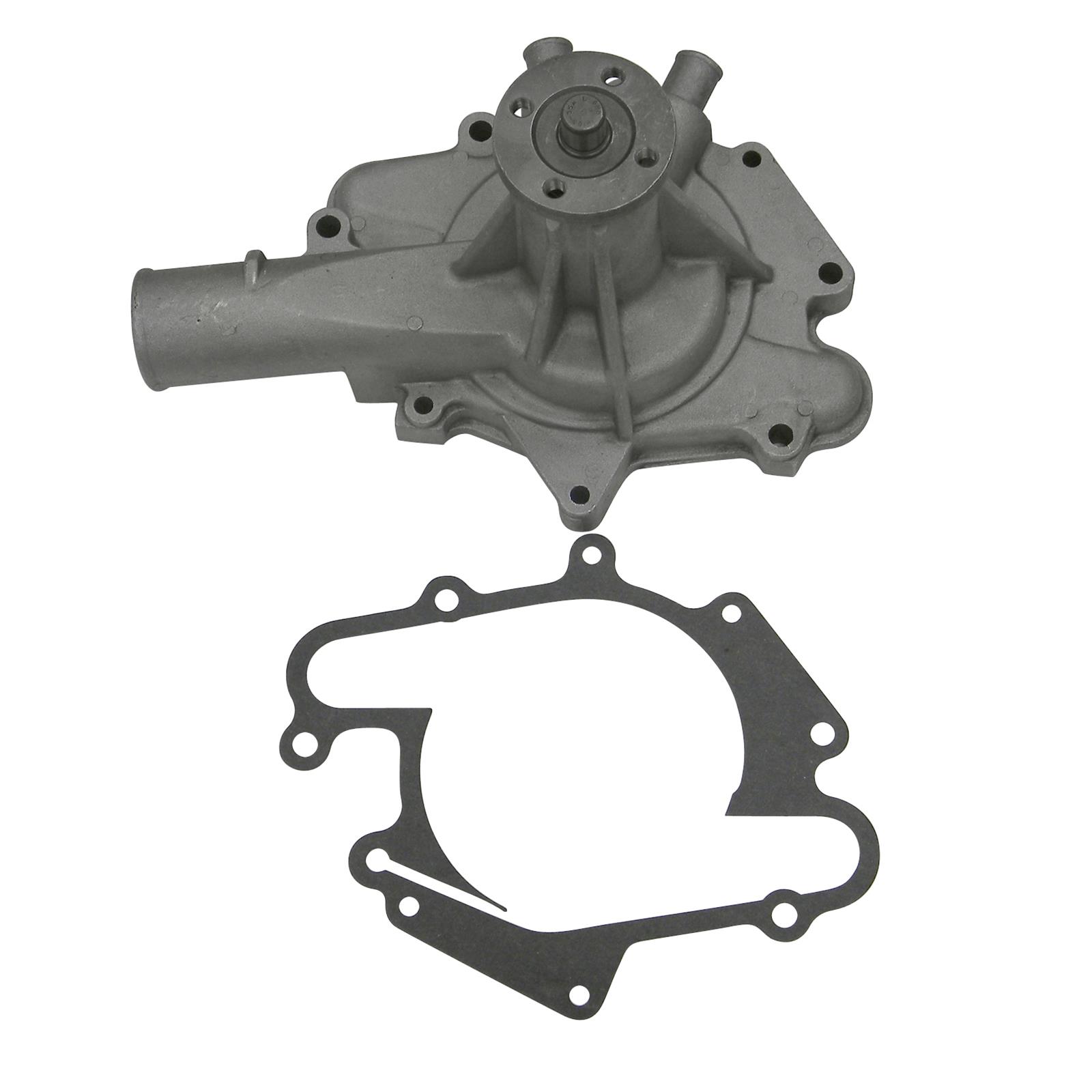

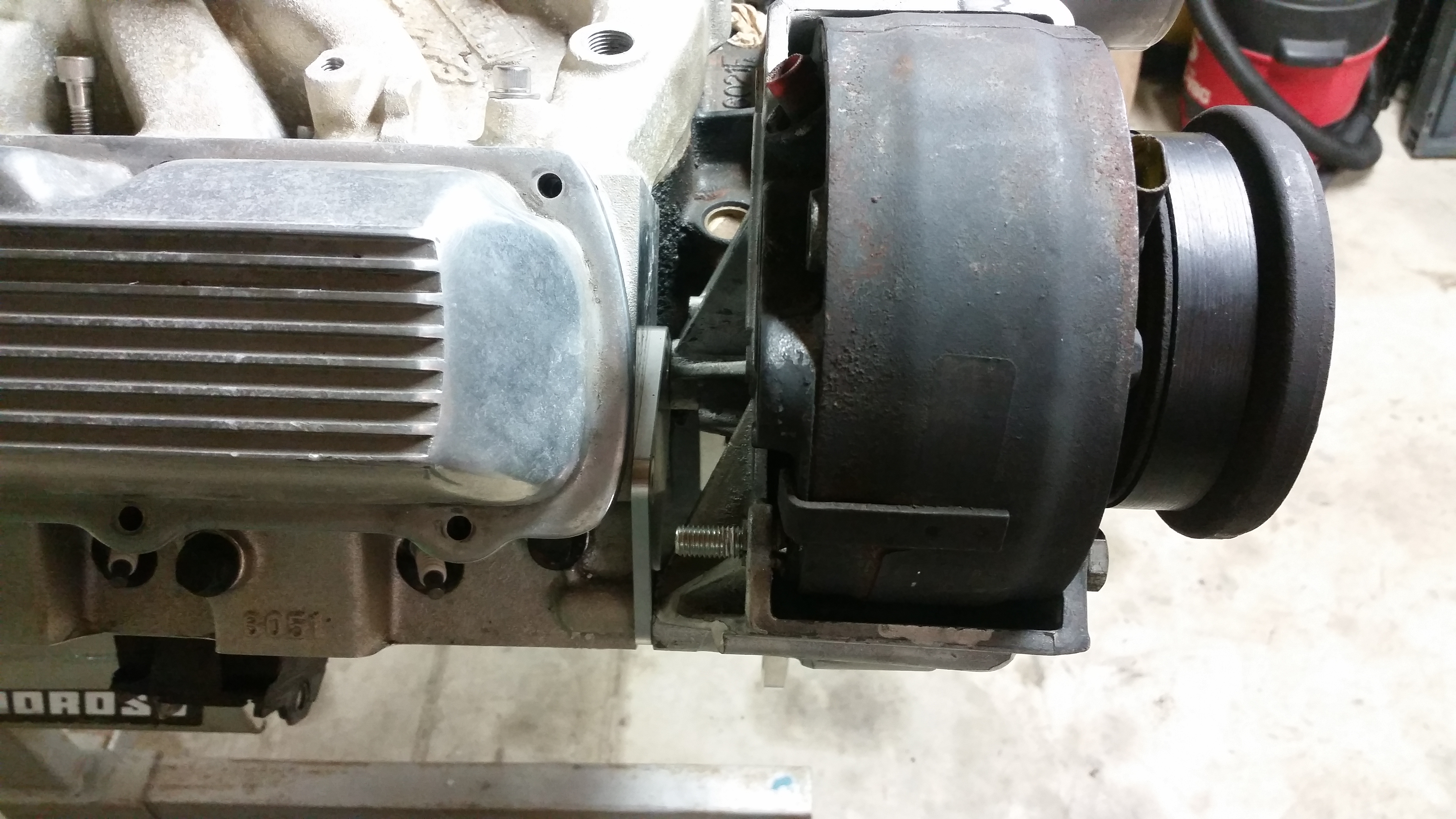

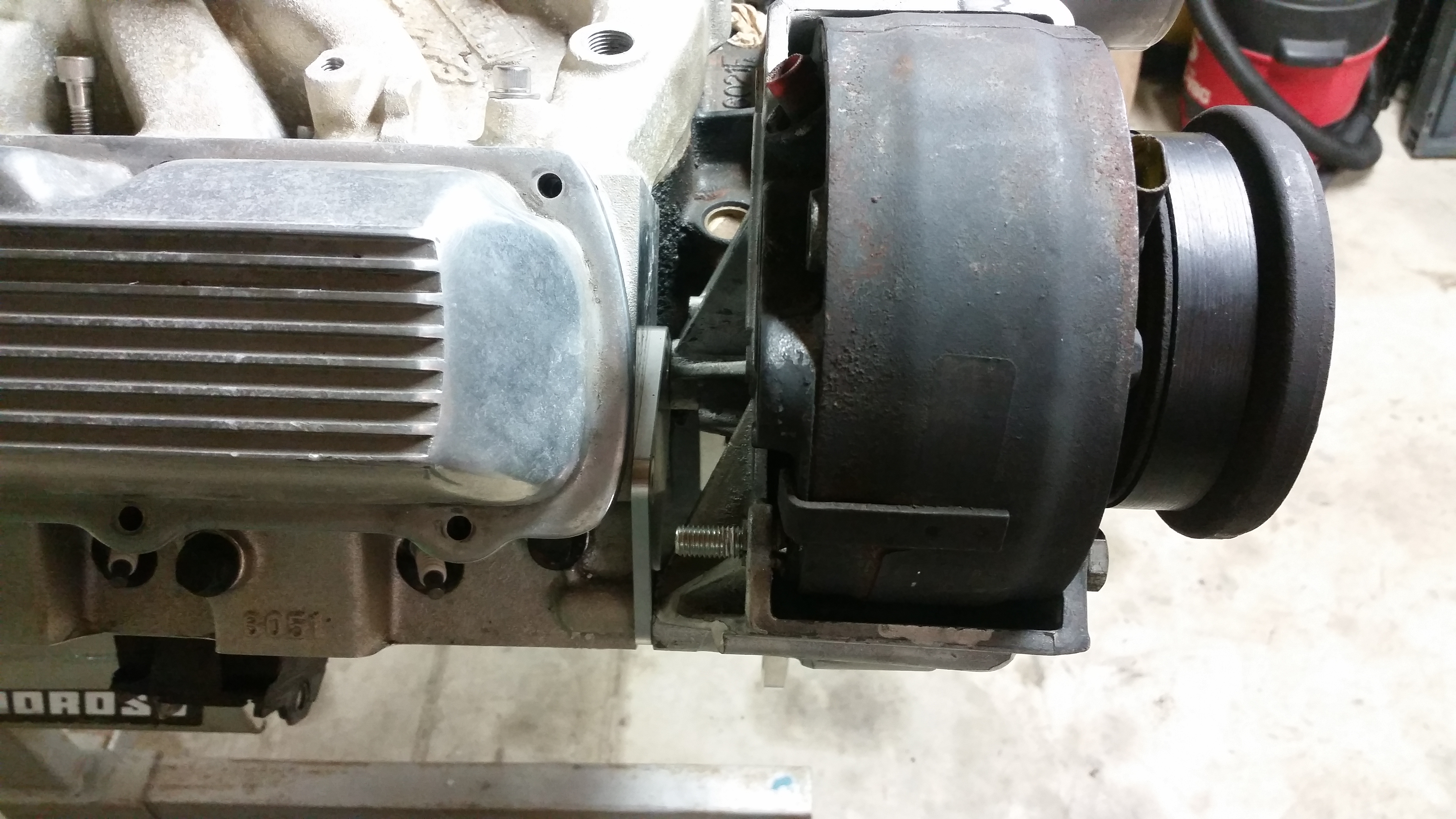

BooooooThe water pump application is a 82 to 85 4.3 V6 diesel, only available in cast iron.

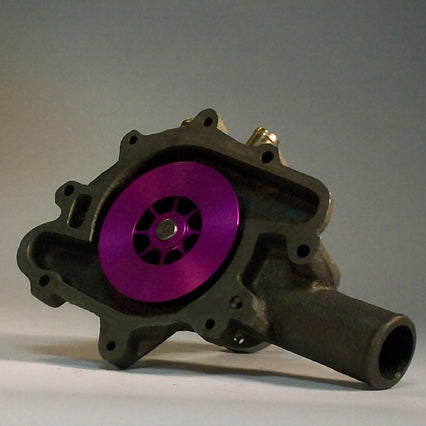

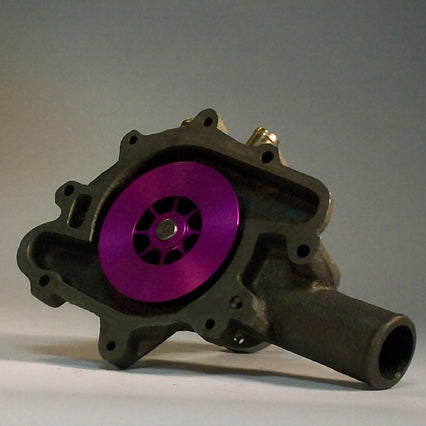

This is the GMB reverse rotation water pump I was refering to.The water pump application is a 82 to 85 4.3 V6 diesel, only available in cast iron. I used a Ford 351 truck crank pulley drilled to the Olds crank bolt pattern.

GMB OE Replacement Water Pumps 130-1240

GMB North America 130-1240 GMB OE Replacement Water Pumps | Summit Racing

Free Shipping - GMB OE Replacement Water Pumps with qualifying orders of $109. Shop Water Pumps, Mechanical at Summit Racing.

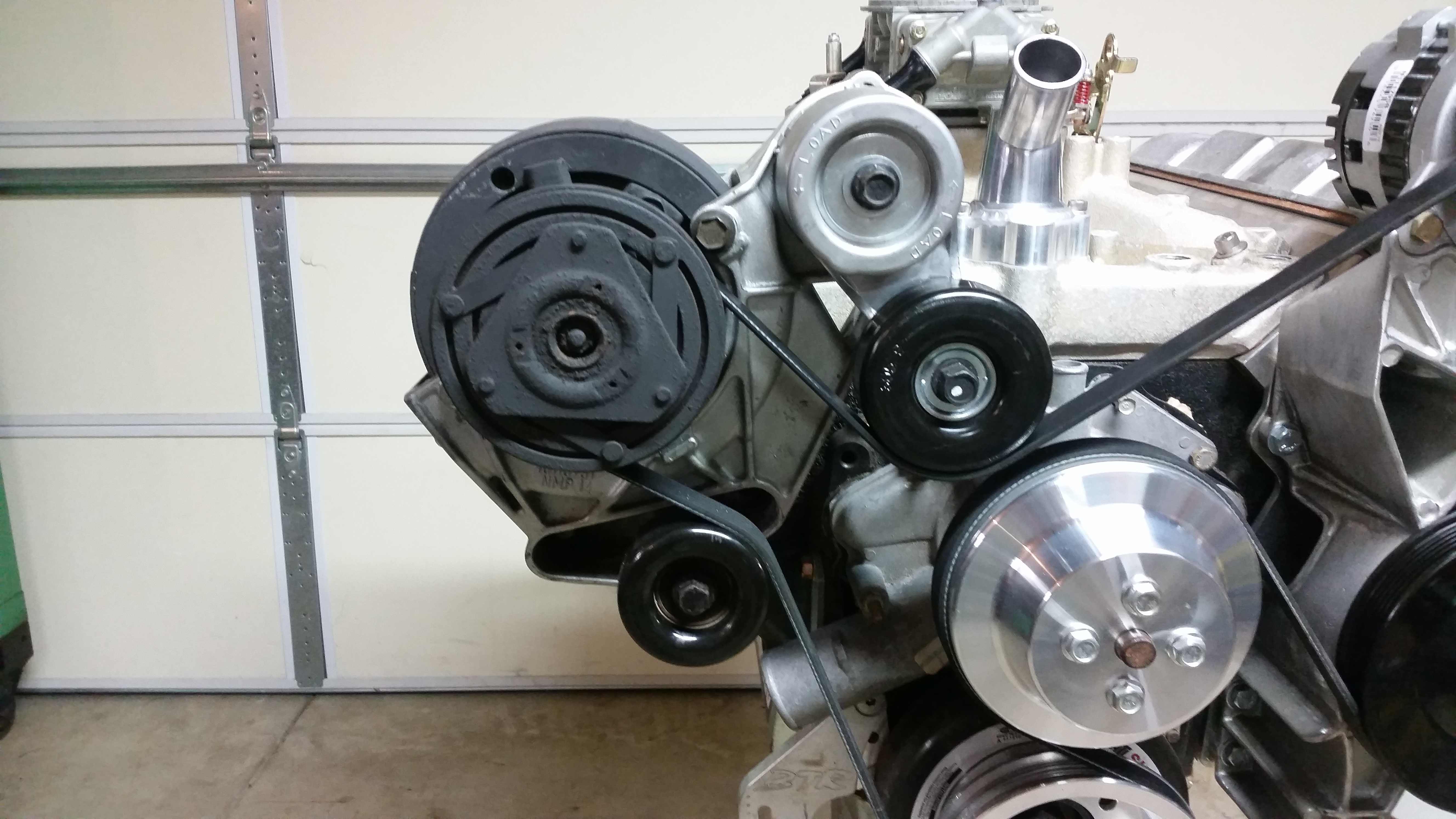

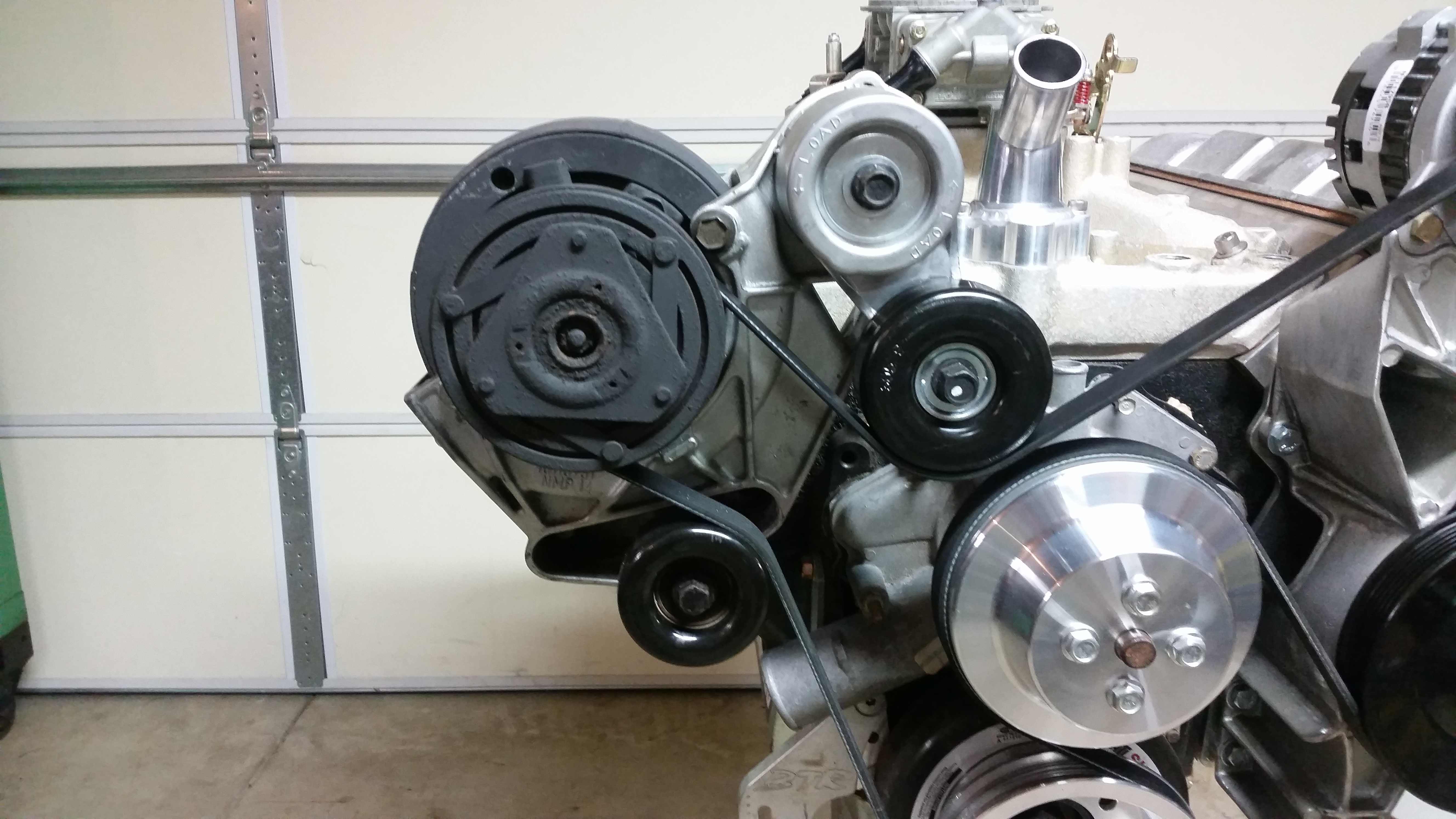

More pics with the AC compressor installed.

As nice as that setup is and as good of an update as I guess it is, it sure does cover up an otherwise beautiful engine. I'll stick with V-belts on my old engines, unless it's driving a supercharger. I've never had an issue with V-belts.

Just one man's opinion. And again, it is a very nice fabrication effort that shows talent.

Just one man's opinion. And again, it is a very nice fabrication effort that shows talent.

The Olds V belt setup is kind of shitty with spacers all over the place. I just ordered one of these while Flowkooler still has them. Putting this on the 374 Olds stroker.

flowkoolerwaterpumps.com

flowkoolerwaterpumps.com

1772 1982-1985 Buick Chevy Oldsmobile 260 262 265 4.3L Vortec water pump

Flowkooler's 1772 pump fits 1982-1985 265/4.3L Chevy Buick and Olds . It has a CNC machined billet impeller designed with an increased vane count and a reduced impeller clearance to achieve greater flow rates, higher head pressure and a more efficient flow than other OEM water pumps. Type II...

flowkoolerwaterpumps.com

flowkoolerwaterpumps.com

I ordered a Flowkooler for my Caddy. Beautiful impeller. It made zero difference in temperature over the GMB solid impeller that it replaced. The GMB was $34. The Flowkooler was $135. I’ll use the GMB on my ‘57 F100 Caddy swap so it wasn’t a total waste.

- Status

- Not open for further replies.

Similar threads

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.