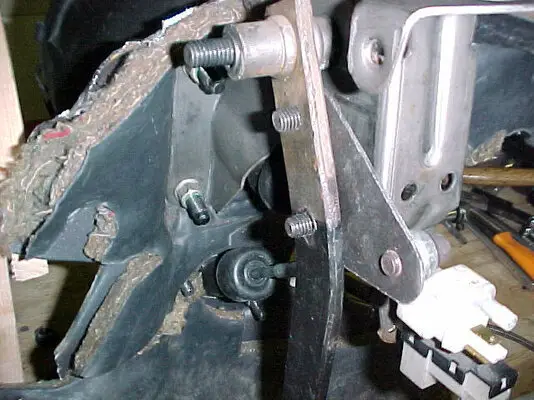

We installed a 4 speed and ripped out the automatic on the 79 Grand Am. The main problem is getting the right angle with the Z bar and pedals. For some reason I can't find the right pedal setup to give me enough travel to completely release the clutch. It seems like the pedal is moving but the Z bar is barely moving, especially the last 2 inches of pedal travel. I've tried drilling holes in the z bar to change the ratio, which results in the pedal being rock hard and completely useless, and still doesn't fully release the clutch because the last 2 inches of pedal travel don't move the Z bar, because the linkage rod from teh pedal to the Z bar is aiming down at a very steep angle. I had it working for a few years on my 78 but it was kind of rediculous because the only way it would work was to have the clutch pedal about 3 inches higher than the brake pedal, to get enough travel

So does anyone have any decent pictures of the correct pedal and z bar for a 79 grand am? I'm about to scrap everything and start over with a hydraulic clutch instead.

Thanks!!

JOE

So does anyone have any decent pictures of the correct pedal and z bar for a 79 grand am? I'm about to scrap everything and start over with a hydraulic clutch instead.

Thanks!!

JOE