Work continues.

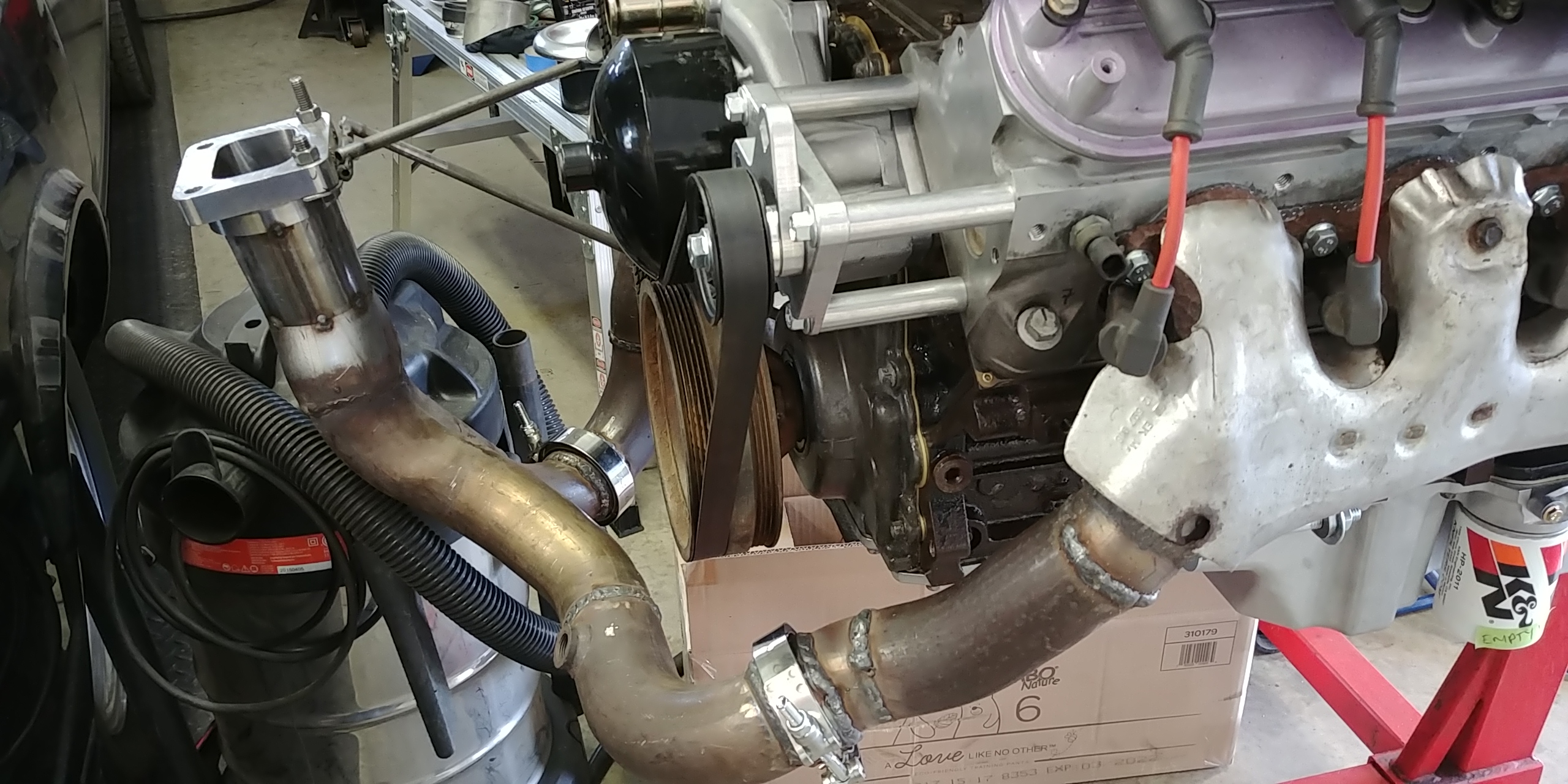

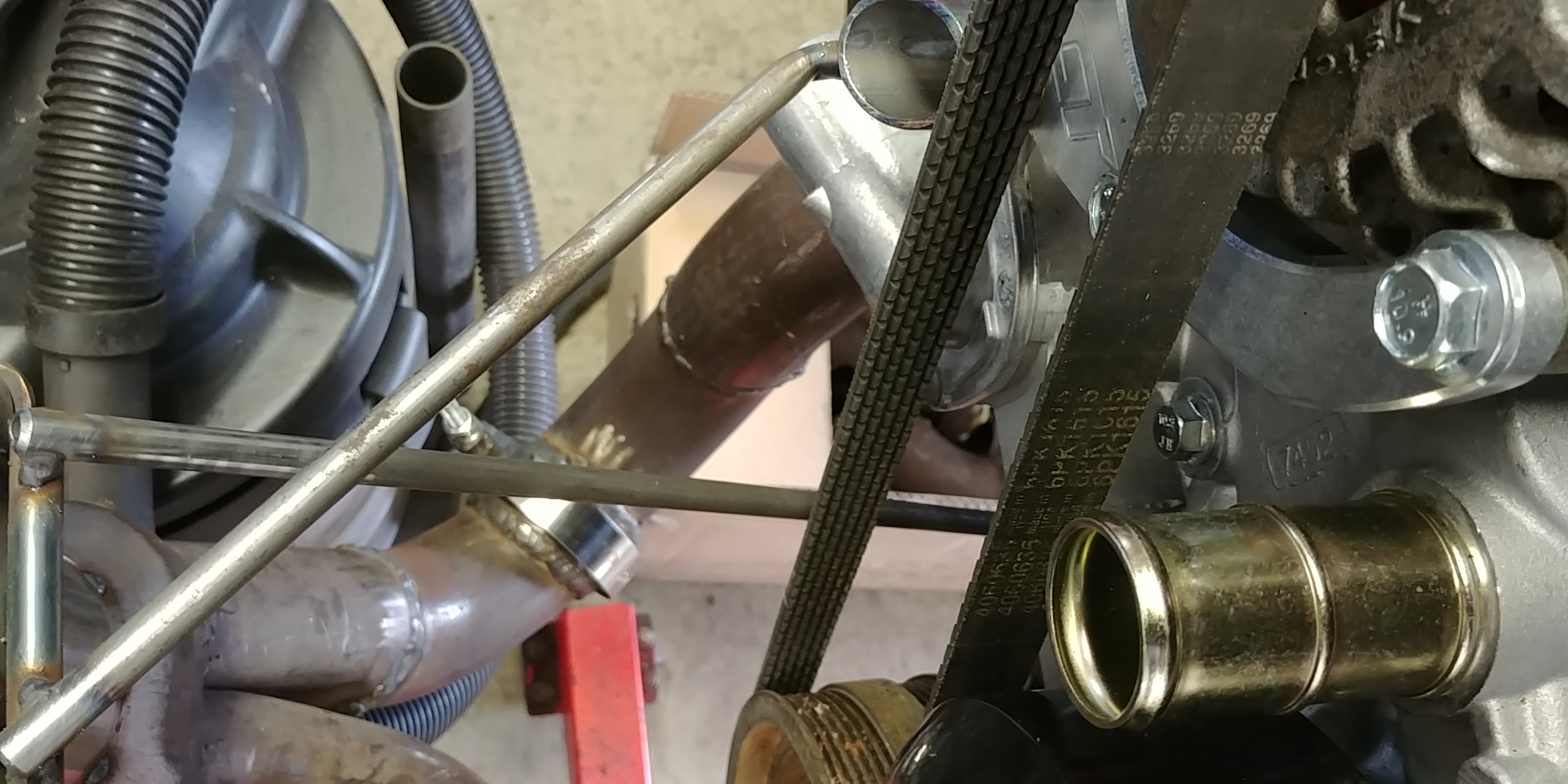

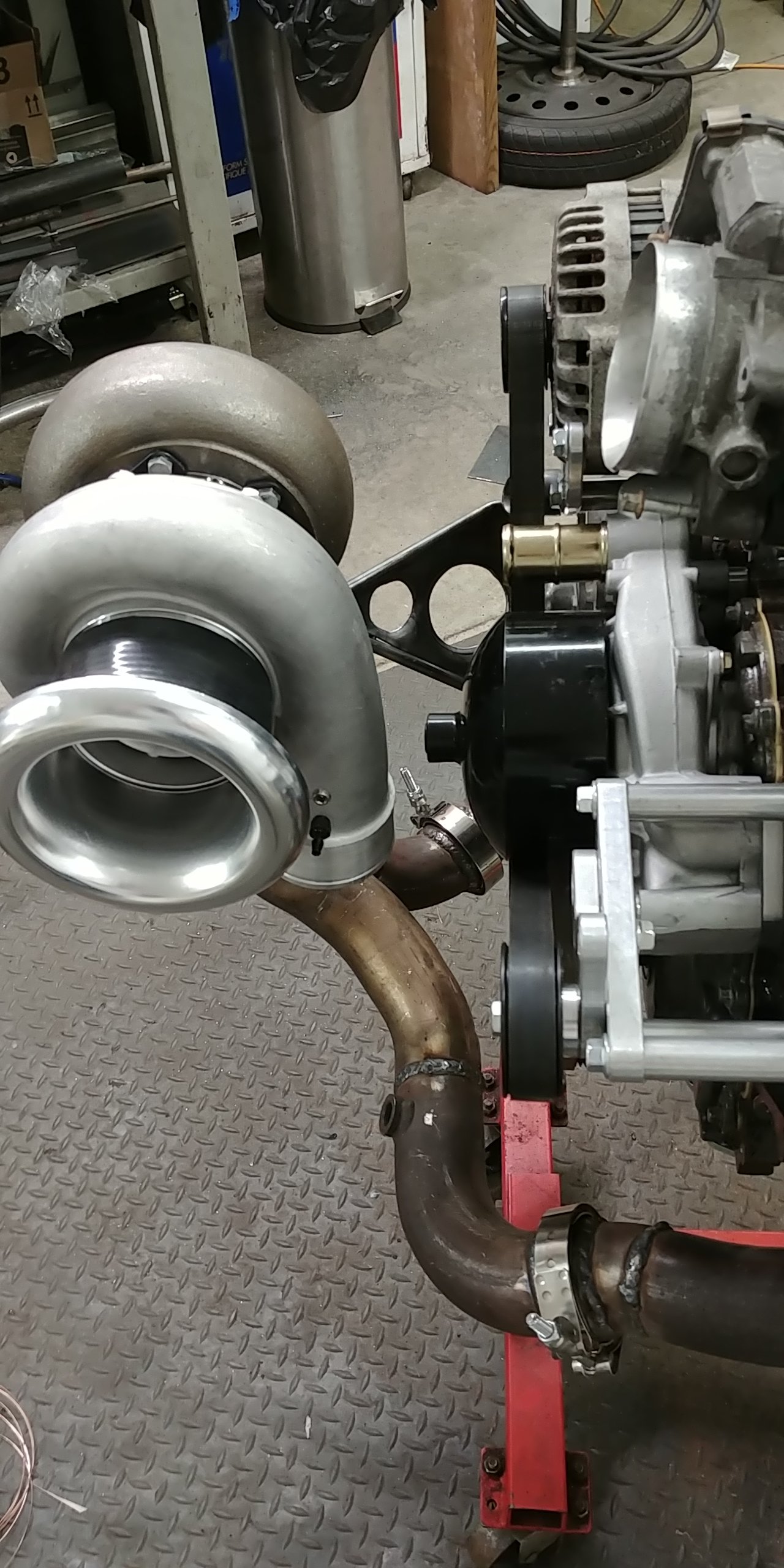

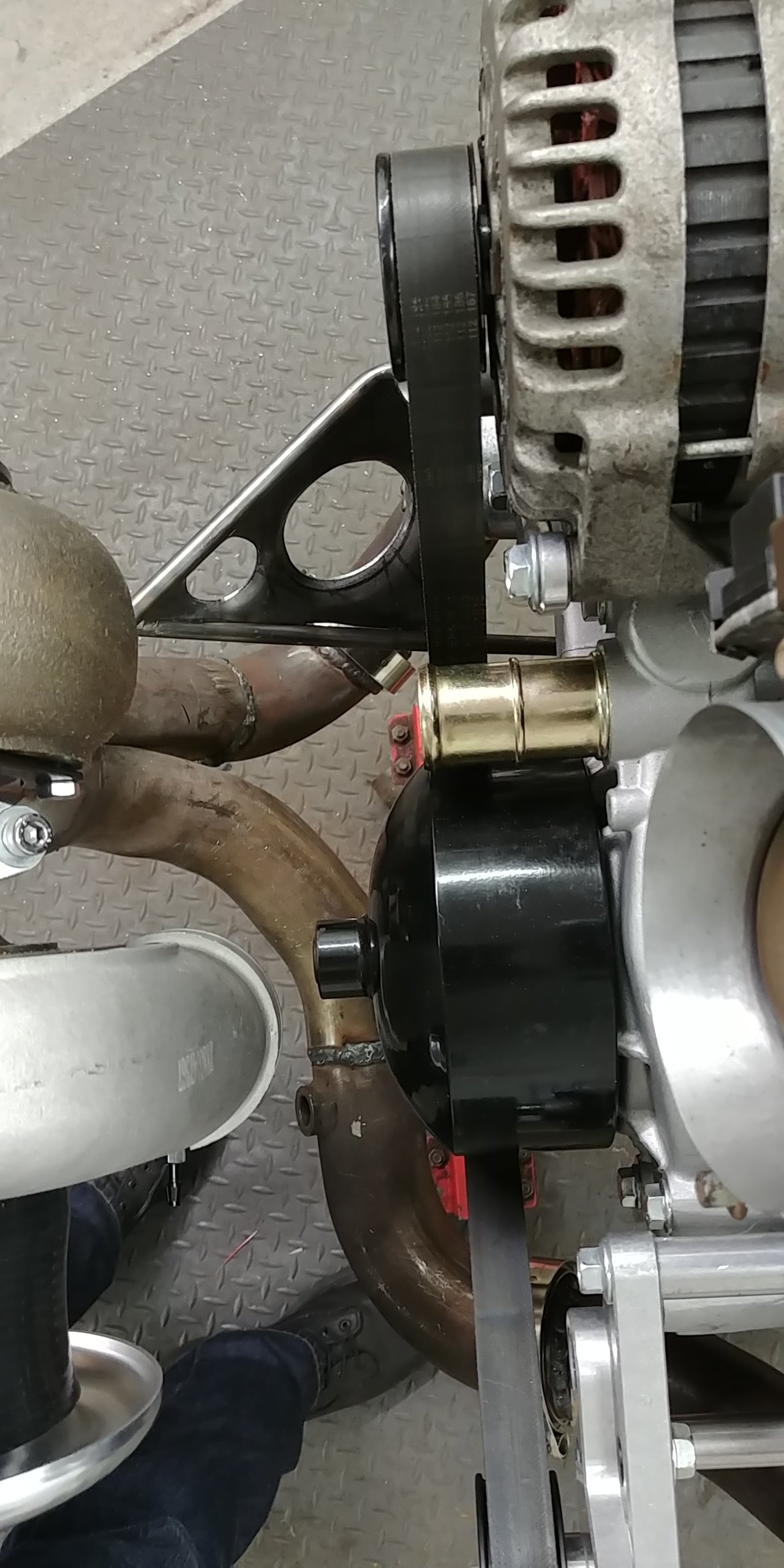

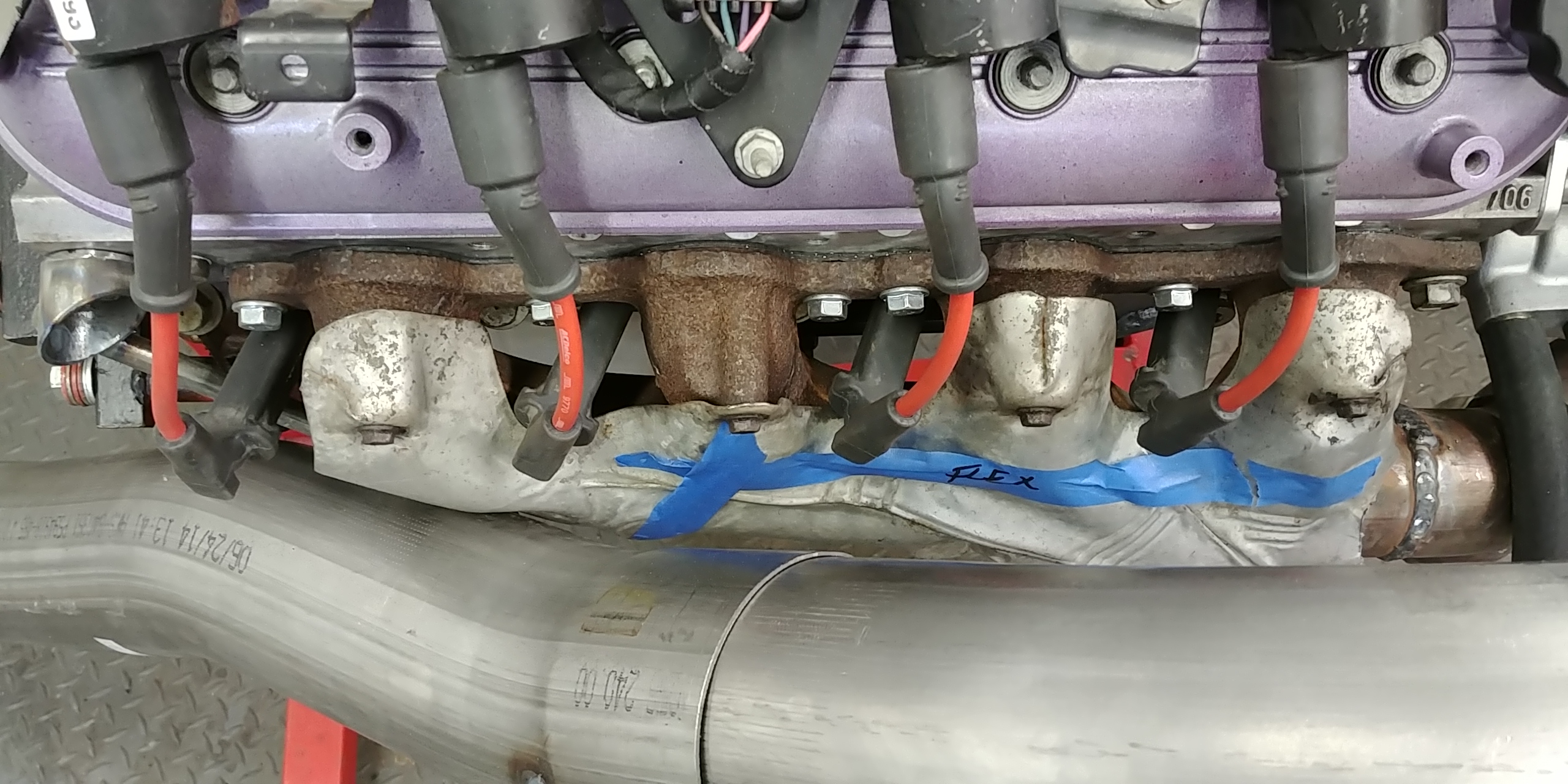

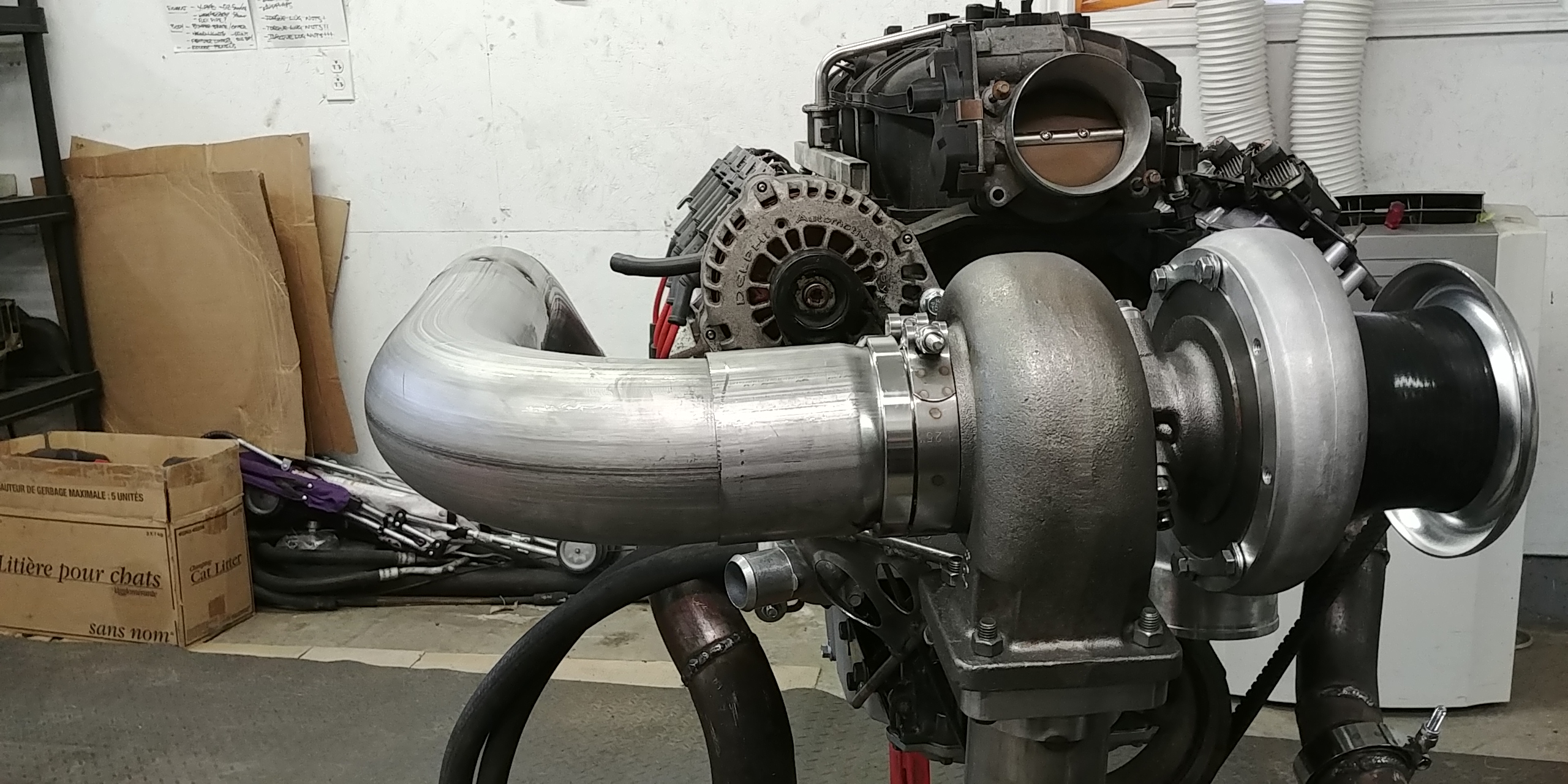

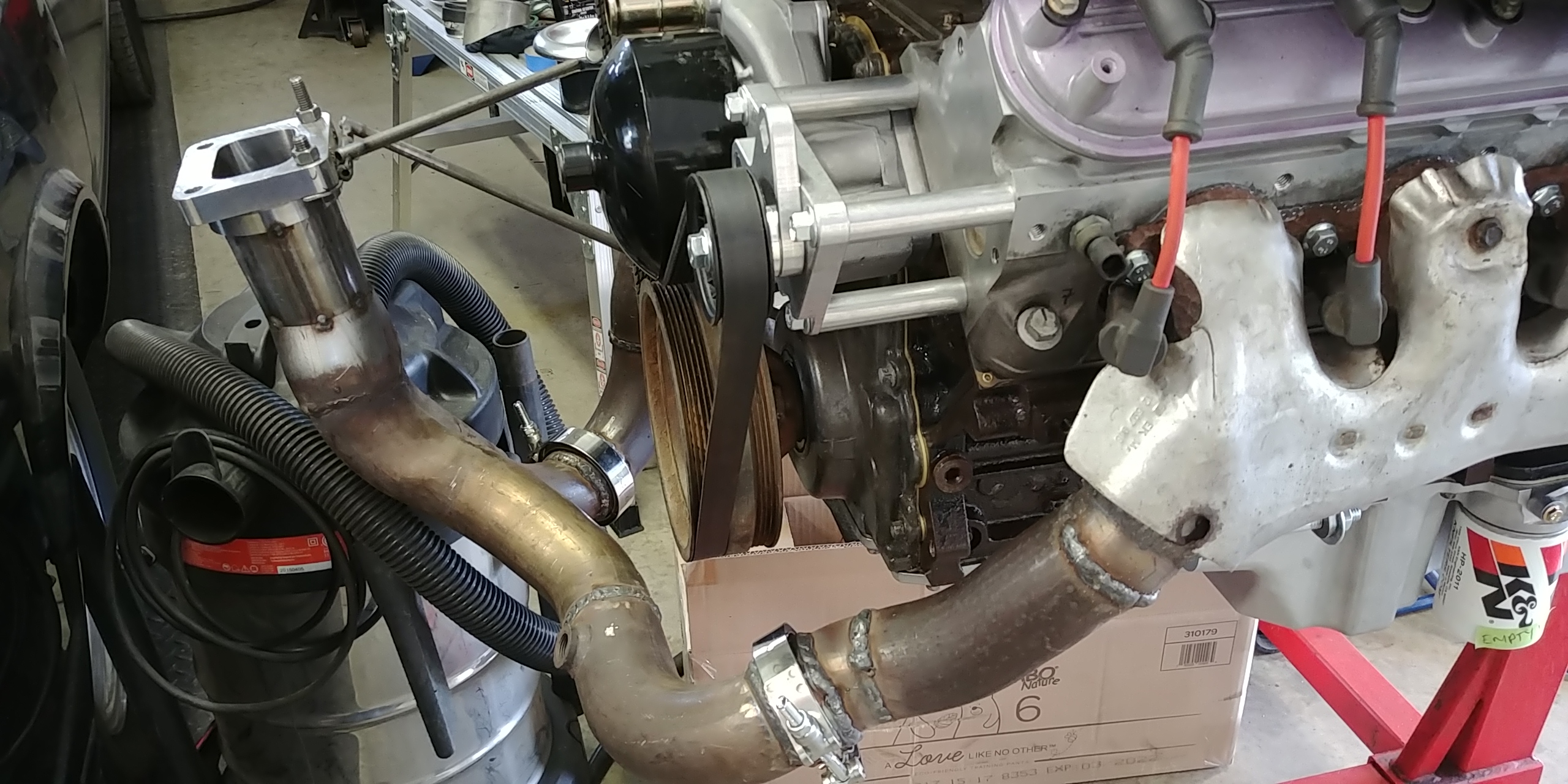

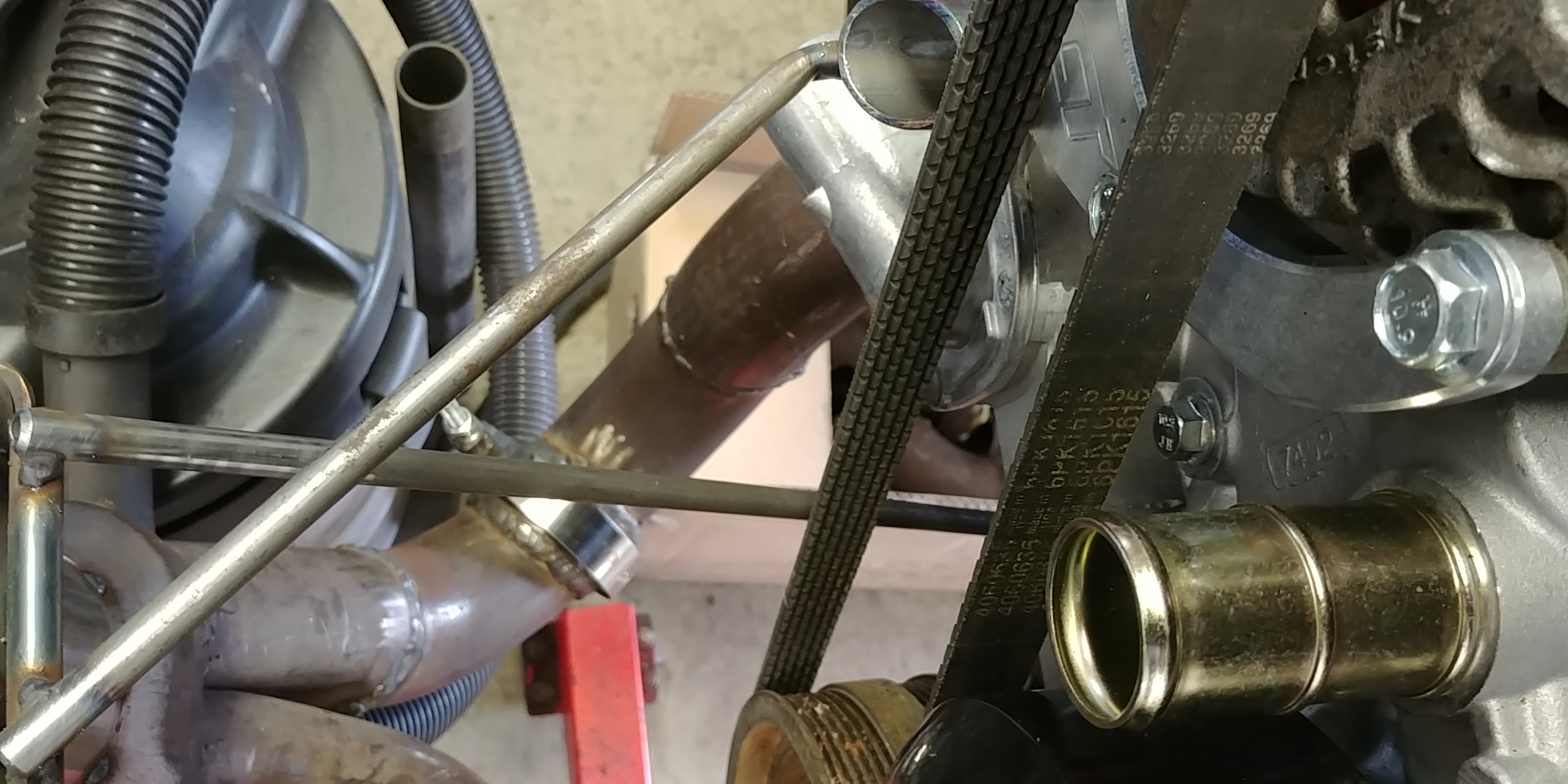

V-bands on. Turbo leaned back a hair to allow the compressor housing to rotate straight down (going to need to fab a new core support now). Turbo bracing is under way - got to leave room for thermal expansion. Especially since discussing the use of flex couplings with my brother made me leary of blowouts/failure - even with lined ones like I have here.

Welding with the stainless steel 316L wire has been a huge learning experience - takes a lot more amps and wire speed to burn it in. Thus more functional and a few bird-sh*t welds were made.

V-bands on. Turbo leaned back a hair to allow the compressor housing to rotate straight down (going to need to fab a new core support now). Turbo bracing is under way - got to leave room for thermal expansion. Especially since discussing the use of flex couplings with my brother made me leary of blowouts/failure - even with lined ones like I have here.

Welding with the stainless steel 316L wire has been a huge learning experience - takes a lot more amps and wire speed to burn it in. Thus more functional and a few bird-sh*t welds were made.