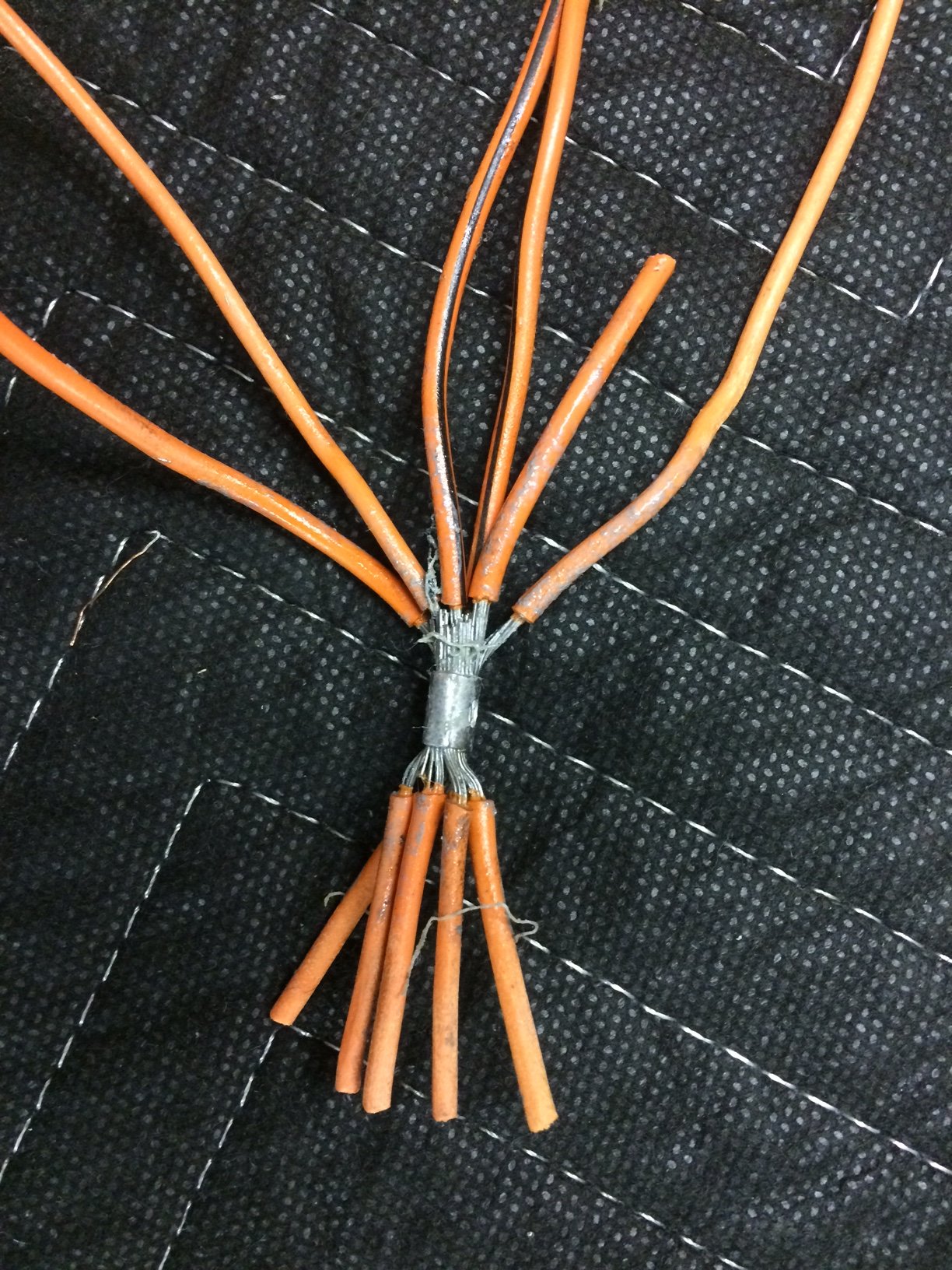

Wiring, mostly, involves a lot of common sense plus a very healthy dose of the proverbial patience of Job. Effectively, you are dealing with a project that can be anywhere from 41 years old at the oldest, through to 31 years old at the newest. Age and decay are the enemy when it comes to wiring because both the insulation and the wire are sensitive; the insulation to UV degradation, and the copper to rust/rot/breakage. Mice, squirrels, anything with the urge and teeth to gnaw can destroy a wiring harness.

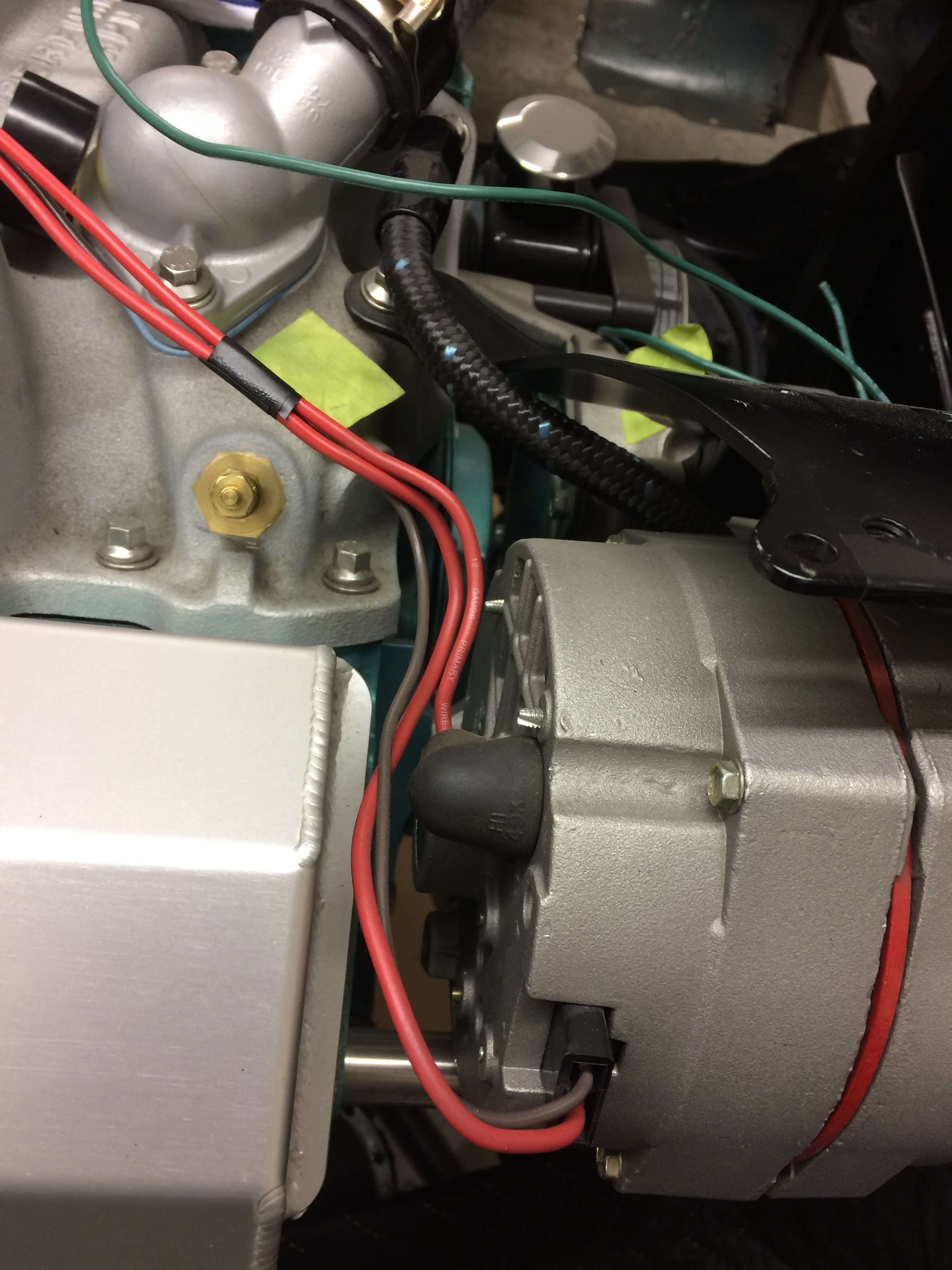

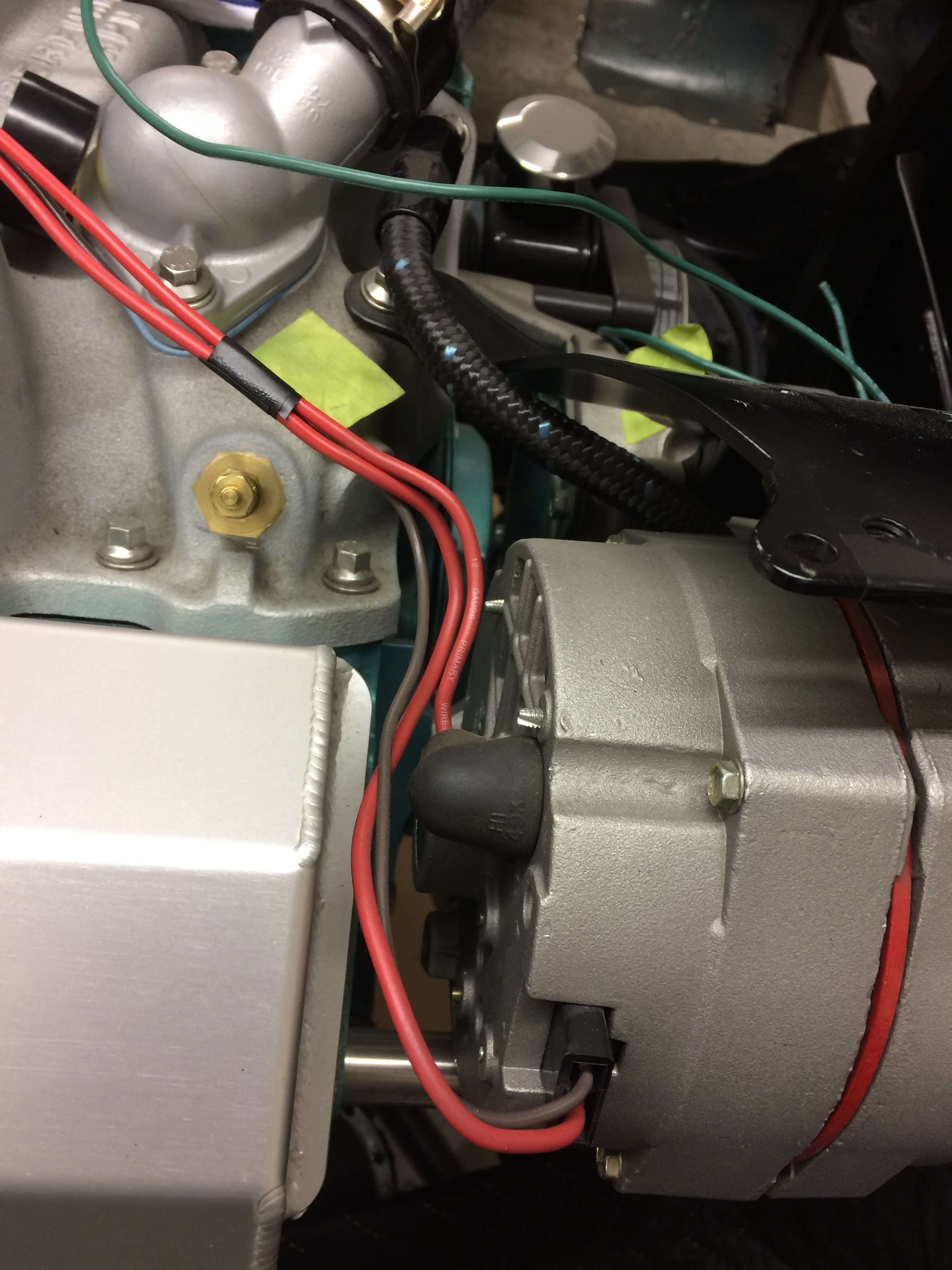

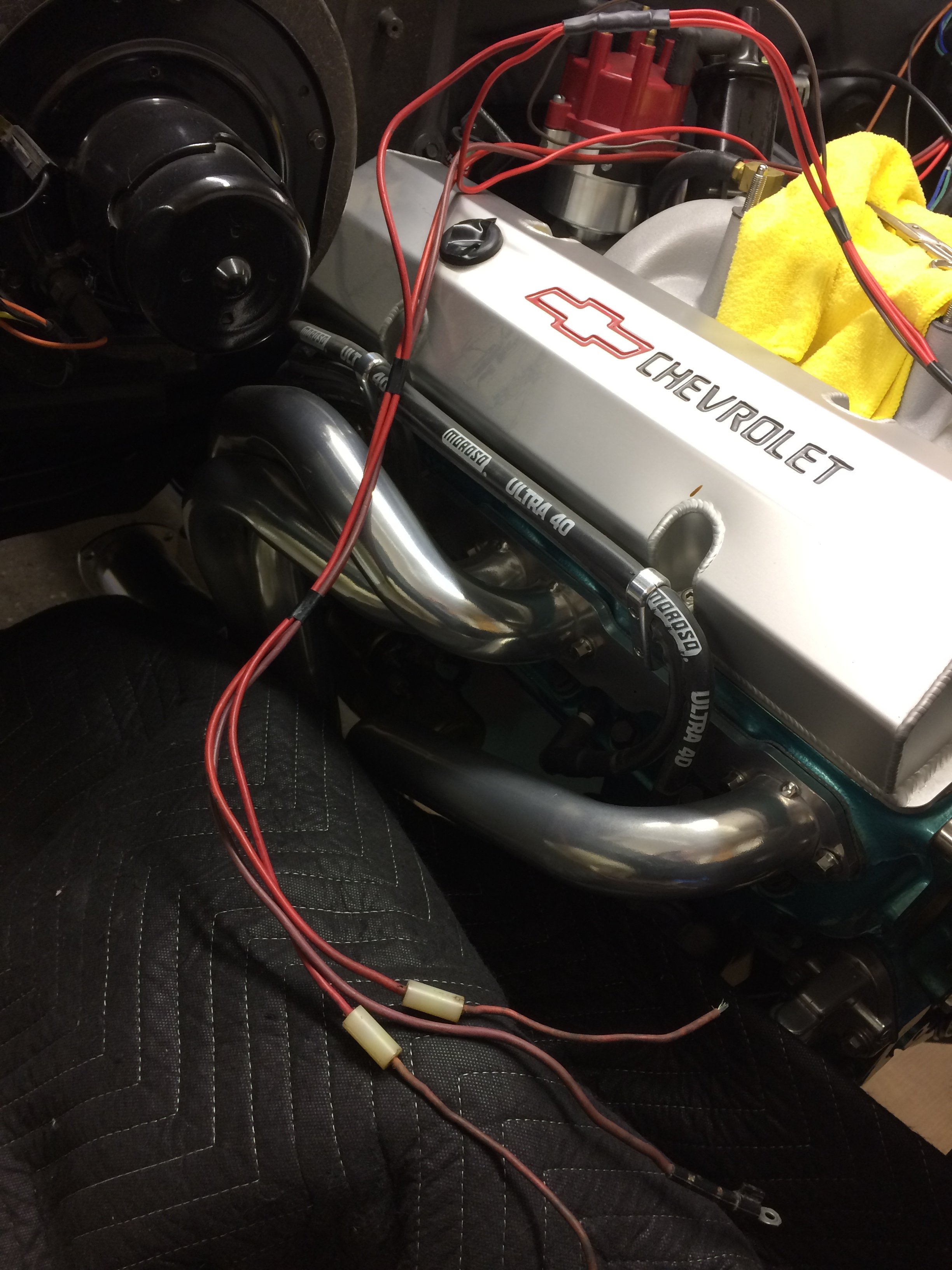

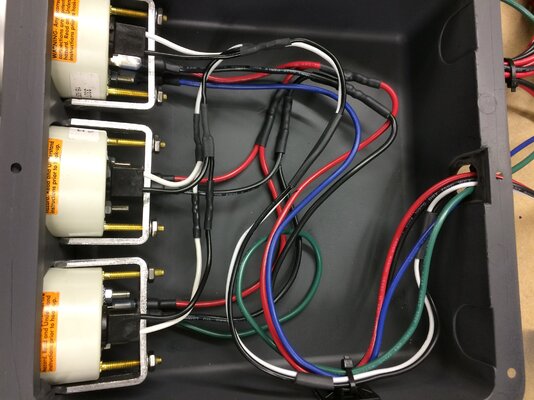

Before tackling any kind of wiring project you will need a correct wiring diagram for the vehicle. Failing that, a good camera with an SD card or a cell phone with a camera and a good memory card. Take LOTS of pictures; they are your best friend when it comes to remembering what goes where. Along with the pics, have a steno pad and a pencil handy to take notes about colors and what color wire is going to where from where. If you plan on repairing or modifying a circuit, do ONLY one at a time, or one portion of it, to keep things simple. If replacing wires, use, at least, the same gauge as the factory used, or better, one gauge heavier. Example, if the circuit uses 16 ga, and you can buy 14 ga in the same color use the heavier gauge. Using the heavier gauge allows easier current flow and less resistance in the wire which means less heat. Wires get hot because they are overloaded or there is high resistance in them due to age and corrosion or bad connections. A hot wire is a fire waiting to happen. Be aware that, in wiring, the smaller the number, the heavier the gauge of wire until you get to "0" which is entering welding cable country and good for battery cables. After that, speak to an electrician.

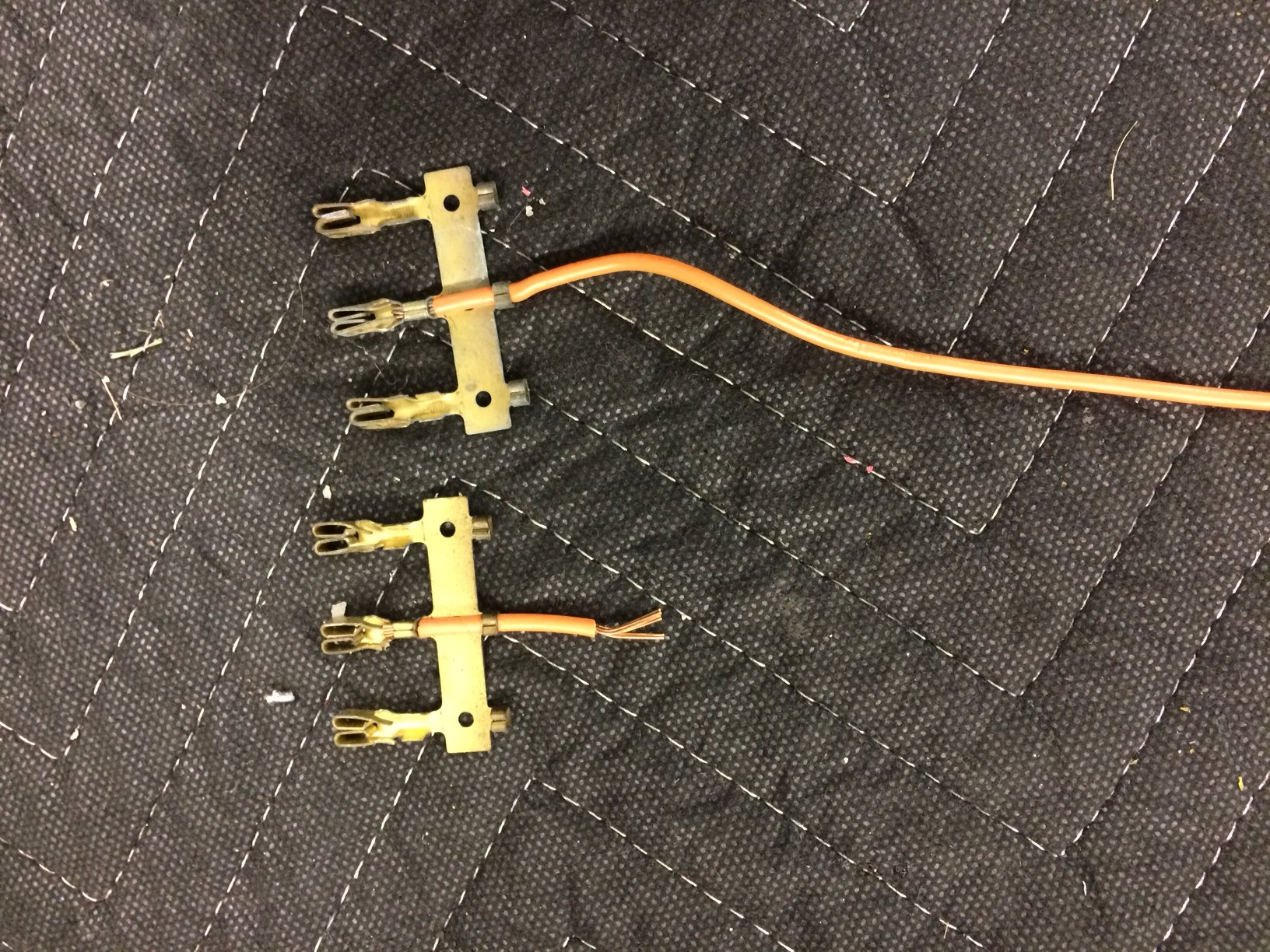

The type of connector to use, and the method of attaching it, is an ongoing argument that has many opinions attached to it. For myself I prefer solder, even if I am working with Weather Pack fittings which are a crimp. A touch or lick of solder once the crimp is made guarantees that the connection won't separate even if Arnie is tugging on it. if you have to go the crimp connector route, get a good crimping tool. If I know that a crimp connection is the only option I try to get the ones minus the plastic sleeve, make the crimp, and slide a length of heat shrink tubing over it and use a butane torch or even a Bic throwaway lighter to shrink it down to obtain some insulation. If you leave the sleeve, then you can use a slightly larger dia of heat shrink, tease it over the plastic sleeve and then heat it up to get it to shrink down. At least doing that you can hide the ugly aspect of the plastic. Where the auto store crimp connectors are the most valuable is in your trunk tool box for the S*** happens problems that occur in the middle of nowhere and a 150 miles away from Bumfuque (Insert name of state here). They will work to get you back on the road and somewhere else where you can the repair correctly.

After all this, wiring is, like pretty much like anything else that gets done around here, a learning process. I hate it so I got reasonably good at it so I would only have to do it once!!

Nick