Fabricating New Harness from C100 Bulkhead Connector to Engine, A/C, Etc.

- Thread starter xcookpac

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I have gotten all my parts together. Today, I detached the engine portion of the C100 connector from the plastic bracket holding it in place next to the lighting portion of c100 harness connector. This connector is used and now that I have taken it apart and find that it looks to be filled with tar/undercoat from the factory.

Question: anyone know of an easy, non-destructive way to remove the tar?

PS Yes, I know I can purchase a new connector but I am frugal (AKA cheap).

PPS. I am tempted to throw the connector into a pot of slowly boiling water. Any thoughts?

Question: anyone know of an easy, non-destructive way to remove the tar?

PS Yes, I know I can purchase a new connector but I am frugal (AKA cheap).

PPS. I am tempted to throw the connector into a pot of slowly boiling water. Any thoughts?

I have gotten all my parts together. Today, I detached the engine portion of the C100 connector from the plastic bracket holding it in place next to the lighting portion of c100 harness connector. This connector is used and now that I have taken it apart and find that it looks to be filled with tar/undercoat from the factory.

Question: anyone know of an easy, non-destructive way to remove the tar?

PS Yes, I know I can purchase a new connector but I am frugal (AKA cheap).

PPS. I am tempted to throw the connector into a pot of slowly boiling water. Any thoughts?

I used contact cleaner and a few small brushes when I cleaned mine up. Does the bulkhead connector in your car have Packard 56 and 59 terminals ? If it does you can get them from a few different places in small quantities. I also bought GXL wire from Wire Barn. They have a website. Very good prices.

One thing I had to change in my 83 was the way the alternator wiring was done. I bought the adaptor but I still had to make the OEM splice over due to the alternator being on the left side with the serpentine setup. Same with the high idle wire for the AC since I have a Holley solenoid on the 4150 carb. I also deleted all of the unused connectors from the original harness.

I still have to get a cable from the alternator output post that will go right to the battery terminal but I dont have the inner fender and battery back in yet.

One piece of advice, buy the two crimpers from American Autowire for the terminals and watch their video on how to crimp that style terminal.

BTW, if you look on ebay theres a bunch of places that sells GXL wire. Some have quite an assortment of colors. Wire Barn is also on there. I used all OEM colors. I went to them due to the fact I couldnt find small spools of purple and pink in any of the marine suppliers in my area. Didnt need to buy a 100' spool of anything. LOL The majority of the wiring that I did in my 81 was marine grade wire. More strands and its tinned so any soldering was easier but the GXL is just as good as OEM.

If you get done and want to unload the partial spools, we can chat.BTW, if you look on ebay theres a bunch of places that sells GXL wire. Some have quite an assortment of colors. Wire Barn is also on there. I used all OEM colors. I went to them due to the fact I couldnt find small spools of purple and pink in any of the marine suppliers in my area. Didnt need to buy a 100' spool of anything. LOL The majority of the wiring that I did in my 81 was marine grade wire. More strands and its tinned so any soldering was easier but the GXL is just as good as OEM.

If you get done and want to unload the partial spools, we can chat.

I'll keep that in mind but Im not sure how much will be left. Some stuff I bought in 10' rolls since its not a real long run from the bulkhead. The 25' rolls were divided between the two cars.

Careful, boiling water may be enough to soften and distort the plastic. You might try an orange oil like 'Goo Gone' to see if it will break down the tar. Washes off with detergent and water.PPS. I am tempted to throw the connector into a pot of slowly boiling water. Any thoughts?

Careful, boiling water may be enough to soften and distort the plastic. You might try an orange oil like 'Goo Gone' to see if it will break down the tar. Washes off with detergent and water.

I recall my dad cleaning up some wiring from a leaky old 396 in his old Impala. I don't recall all the reasoning behind it, something to do with gage wires under the hood, but he had me and my brother with rags and turpentine cleaning off goo and oil off all the wiring. Stinky as hell, and we were wearing mom's dishwashing gloves, but it worked like a charm cleaning the wiring. Not sure if it would make a difference on the sealer, though.

I used Brakleen on Clutch's square body.. It's a water protectant, so make sure you replace the diabolical grease.

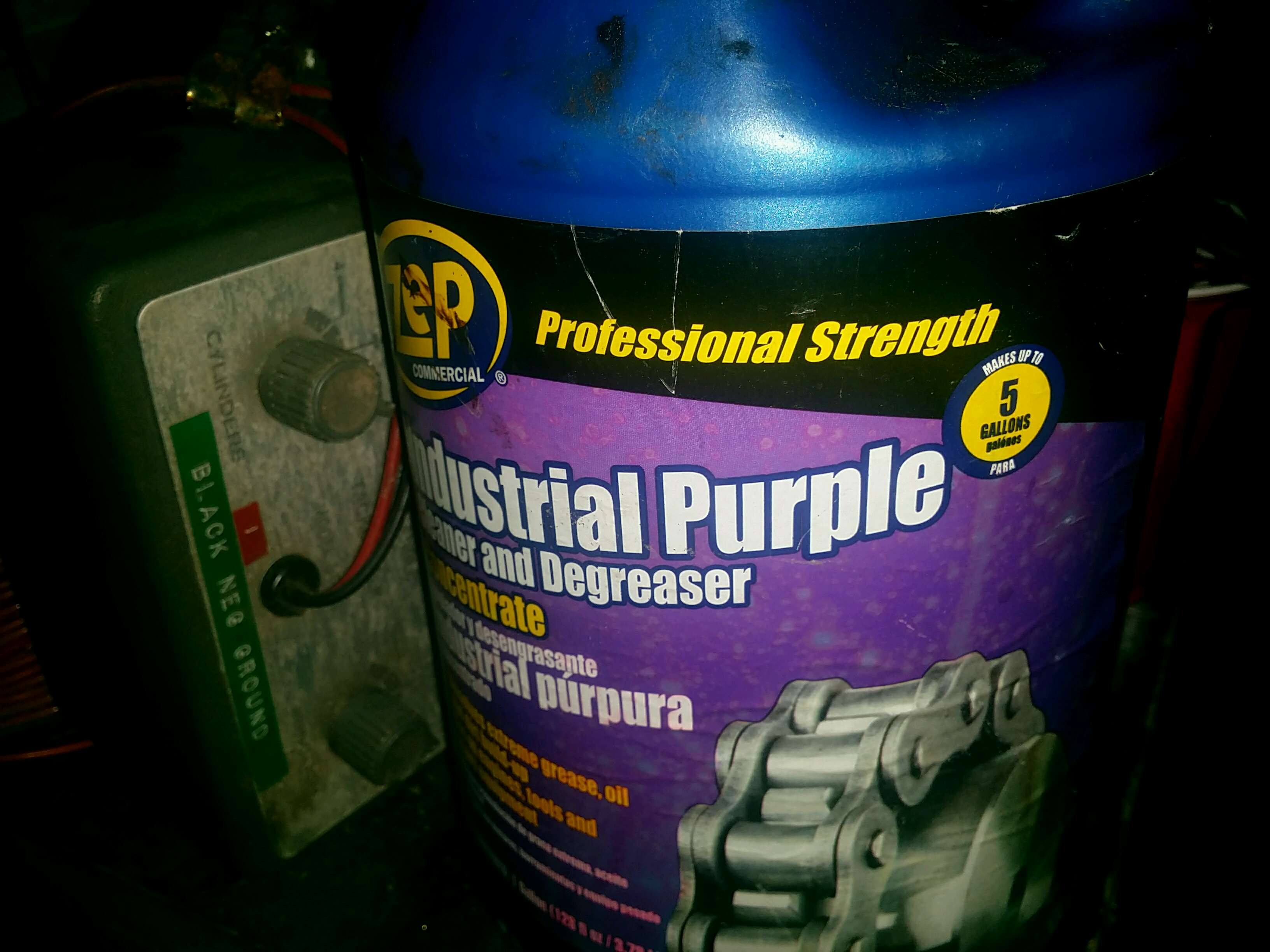

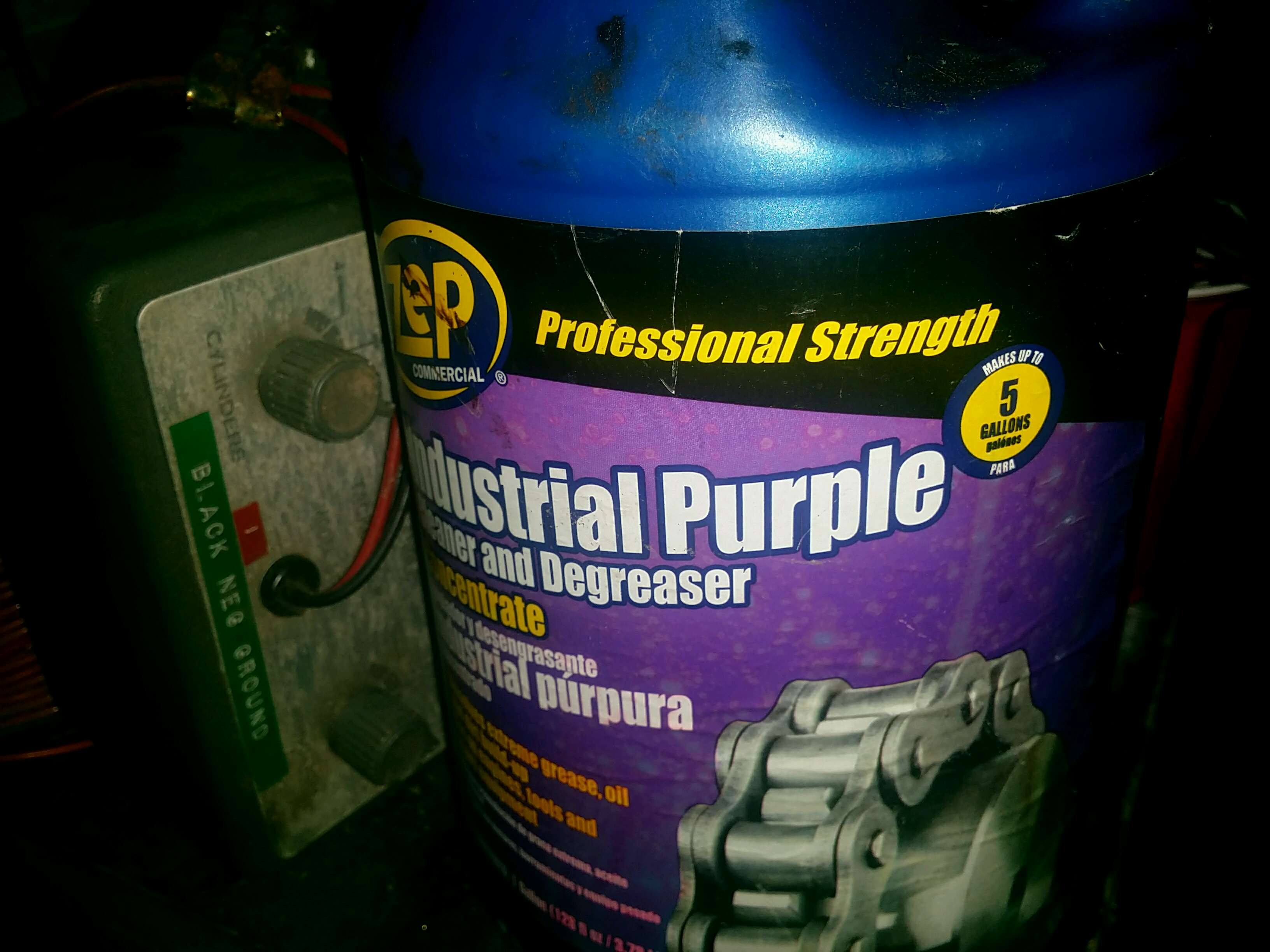

I soaked the C100 engine harness connector in gasoline (in an old steel coffee can) for 24 hours. When I took the connector out of the coffee can this morning, I found the connector intact but the tar/undercoat had turned into a thick gelatine. I have now transferred the connector to a crockpot* set on low with a 50/50 mix of ZEP purple degreaser and water. My intention is to leave the part in the crock pot for 24 hours on low and attach a shake-and-bake sander to the crockpot for the last hour or two. I will likely update tomorrow on whether this has worked effectively and without damage.

*- the crockpot is a $5 crockpot from the local flea market (not my wife's crockpot for cooking dinner).

*- the crockpot is a $5 crockpot from the local flea market (not my wife's crockpot for cooking dinner).

Last edited:

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 183

- Replies

- 14

- Views

- 480

- Replies

- 9

- Views

- 292

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.