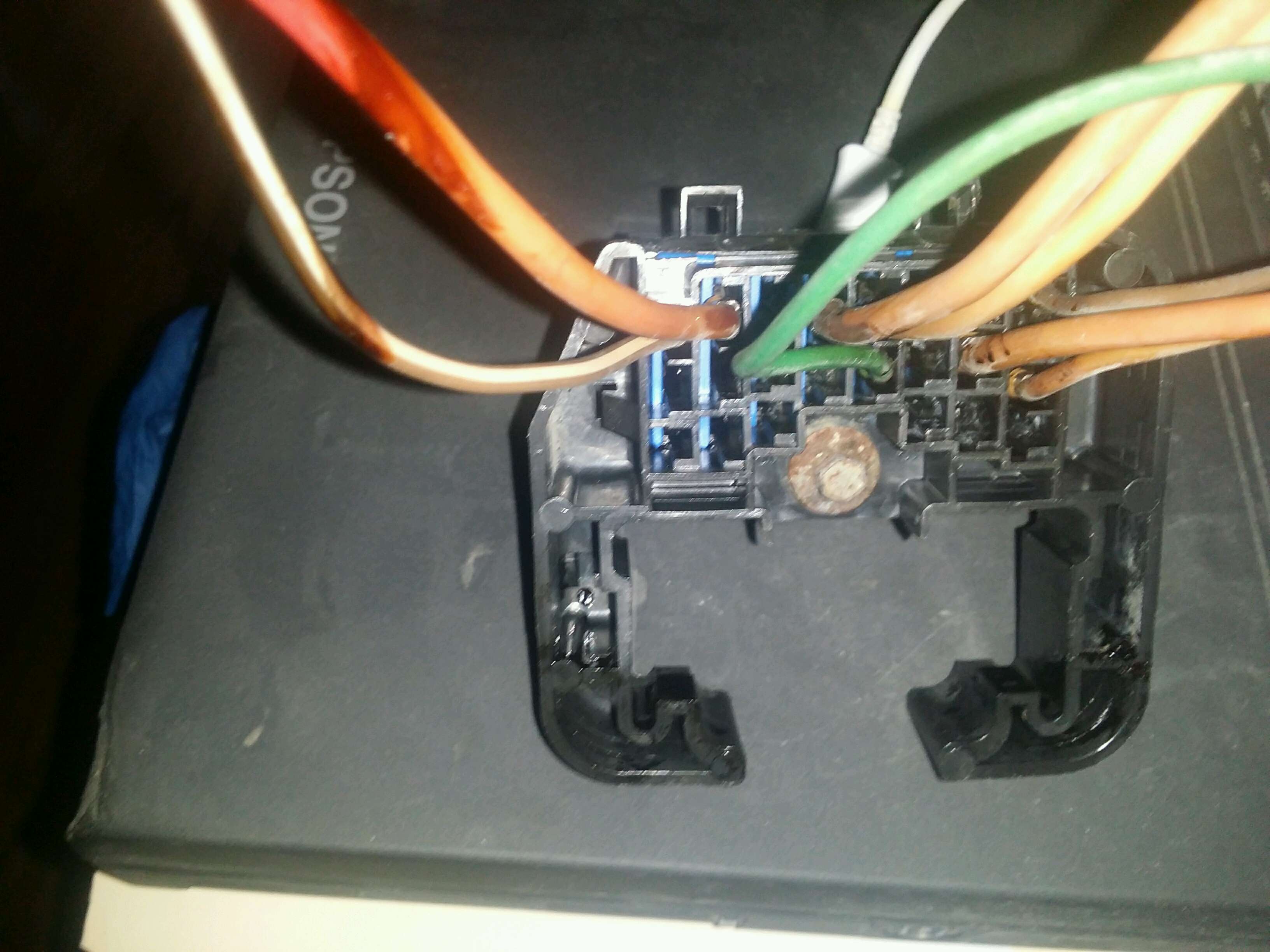

One piece of advice, buy the two crimpers from American Autowire for the terminals and watch their video on how to crimp that style terminal.

See link and tell me if these are the crimpers that you are recommending.

Link: https://www.summitracing.com/parts/aww-510586

Many thanks.

PS Why two crimpers?