Details.....

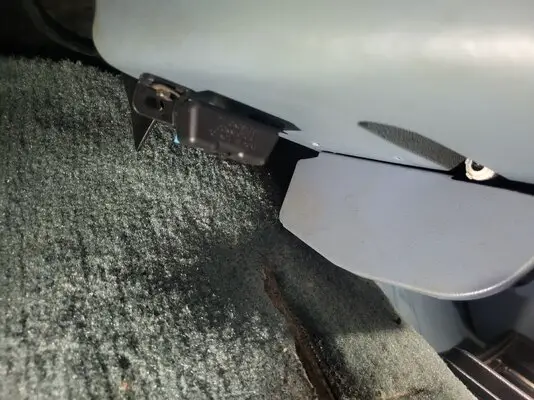

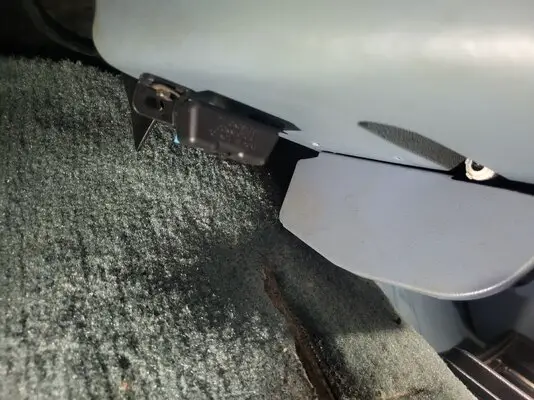

The harness has a diagnostic port. I mounted it in the factory location.

The harness also had a provision for a check engine light. That wire was in the part of the harness that goes into the car. I found a lens thanks to Steve (El Camino Kid LLC) and had an original GM bulb socket pigtail that fit the metal bulb housing in the cluster. You can see the light working in my first video that I will post later.

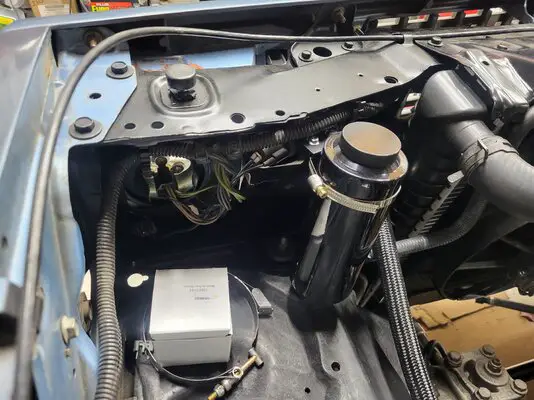

Also the tach was kind of a pain. So the E67 computer has a white wire output, but the signal is weak. When I first wired it up I simply ran the white wire from the computer to the original tach wire. It did not work

The instructions were to run a 12 volt switched wire out of the bulkhead connector that the tach wire comes out of. This is a connector attached over at the fuse/relay box. They want you to use a 5,000 ohm resistor on this wire. They want this in series with the tach wire from the computer. I ran them to a steel crimp connector and the the other side of the connector is the wire to the tach. That got the tach working but it was reading half the rpm it should. After more research I found that the tach output signal out of the computer is the same as a 4 cylinder. My factory tach did not have a selector/dipswitch. My options were:

Have someone modifiy the tune by changing the tach calibration ($$$)

Buy the HP Tuner software and modify it myself (More $$$)

Buy the Dakota Digital conversion box (Again, more $$$)

I actually ordered the Dakota Digital box but before it showed up I found a super nice reproduction/ custom tachometer from the Parts Place on Ebay. It looks like the original tach but goes to 8,000 rpms which is nice since the factory only goes to 6,000 and my camshaft shifts at 6600. The tach showed up and to my surprise has a dipswitch for 4, 6 or 8 cylinder. I set it to 4 cylinder and the tach is now accurate.. I corroborated it with my scan tool at different rpms. It was money well spent! So I sent the Dakota Digital box back.