Nothing on the ground or shop floor. Just a wet pan. What I saw when I pulled the 5.3/65E flexplate led me to replace the rear main, rear cover and oil pan gaskets/seals.I hear ya on the age thing. To scary jello I'm sorry we kinda hijacked your thread.

Texas when you observed the leak what did you see?

Mine is just a small maybe inch and half puddle after a minute or so run time and it only appears after motor is off. In other words if it were my seal or anything on rear of crank wouldn't it be spewed everywhere?

I see one trail of oil maybe quarter inch coming down rear pan.

four questions

- Thread starter doood

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

thank you.The procedure

both my brother's 02 Sierra and my 08 Sierra call only for threadlocker. No mention of sealer....I don't remember looking closely enough at crank when I installed it but even if the holes for flexplate go all the way into the crank case wouldn't thread locker still stop oil from seeping out? I mean it's thread locker. It's in the threads and it can't go anywhere?

View attachment 173063

View attachment 173064

I will check to see if the bolts are through or blind. I will use blue locktight because it appears to be similar to the medium strength GM threadlocker part number shown in your service manual. I agree, it'll be good enough.

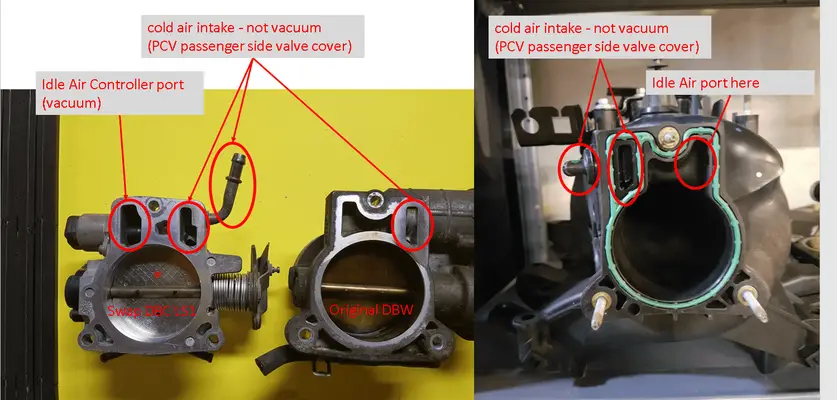

I realized that the LS1 throttle body with my truck manifold from a drive by wire setup now has two hose barbs to the same passage bypassing the butterfly for the PCV clean air inlet to the passenger side valve cover. This is from mixing-matching parts. So, now I either will press/epoxy a hose barb into the evap hole or use the PCV hose barb on top of the manifold, which unfortunately is pointing at the driver's side. I got this stupid spare hose barb pointing straight up on the throttle body; I'm going to see if I can pull it out after heating the aluminum of the throttle body.All the questions because I don't have a service manual.... If it's annoying, please point me to a pirate service manual online.

1) LM7 5.3l crate engine (ATK) has instructions to "seal the bolts joining flywheel/flexplate to crank" to avoid oil leak. I found discussion in some LS GTO forum discussing oil contamination of clutch to use PTFE (teflon) paste for this purpose. I asked ATK what to use (RTV?).

2) Do most NA LS builds NOT use an oil cooler? Seems my donor truck (2WD Silverado) did not have stock oil cooler because there is a delete cover above the oil filter. Strangely, my dakota digital dash came with an additional oil cooler delete cover (for use with included oil pressure instrument). My aftermarket radiator, marketed as specifically G-Body, does not have an oil cooler. Soooo, my radiator is bitchin' and I'm pretty sure I don't need the oil cooler. Comments? Out of curiosity, is this where turbo LS guys take oil for the spools?

3) Crate engine instructions tell me to prime the oil pump with oil before attempting start. I've been aware of this and seen a Youtuber use a drill pump to fill the engine from the oil galley port (normally plugged) and I've seen some other guy use a funnel to simply prime the pump and fill the oil filter. Both inserted rubber fuel line or whatever flex tubing well into the oil galley port. I get the feeling the funnel is better and the drill pump is overkill.

4) I installed LS6 valley cover with integral PCV valve and it fits perfectly. I have a blank-off for the driver's side valve cover PCV nipple; don't know if I'm going to try to pull the press-fit nipple out of the valve cover and use the blank-off or just cap it with a jimmy hat. If I understand correctly, I can simply blank off the driver's side valve cover PCV nipple and route the LS6 PCV nipple to the intake manifold vacuum. I will connect the passenger side valve cover nipple on the LS1 throttle body bypass hole opposite the idle air valve for "fresh air in". If I want to get fancier, I can put a fuel filter or catch can before the intake manifold.

Be wary of the throttle body ports. Be sure you TB is compatible with your intake via all of the ports on the mounting surfaces line up. If any of them don't, then you will not be able to get this to run correctly. Very easy to check. Any additional vacuum ports can be capped. But it is ultra-critical to make sure that you have the engine breathing through those ports, implying you can't plug ALL of them off. If you do, then it will be applying vacuum to things that aren't supposed to be.

Regarding the bolt holes in the crank - yes they are pass through and blue loctite or teflon sealer needed. If somehow you have one leak, it will be minor. I put loctite on them and have never had an issue. And I actually torque those.

Regarding the bolt holes in the crank - yes they are pass through and blue loctite or teflon sealer needed. If somehow you have one leak, it will be minor. I put loctite on them and have never had an issue. And I actually torque those.

I have some spares on hand. This is a 6.0 crank.

View attachment 173126

My LR4 is the same. With that said, I never sealed mine and not being a pressurized bearing I am confident it won't leak with torqued flywheel bolts.

Do what you will help you sleep at nnight

The rear main bearing is spraying oil right at this location i believeI have some spares on hand. This is a 6.0 crank.

View attachment 173126

My LR4 is the same. With that said, I never sealed mine and not being a pressurized bearing I am confident it won't leak with torqued flywheel bolts.

Do what you will help you sleep at night.

Since you are being helpful, I have uploaded a picture of intake manifold and original and swapped throttle body. It appears that the DBW uses the butterfly to control idle air whereas the old LS1 DBC from F-body uses IAC and has a hole in the butterfly plate. The IAC port matches up to the vacuum and the pass-through for cold air PCV vent to passenger side valve cover matches up to the cold air (non-vacuum) pass-through of the truck manifold. It appears I have two hose barbs for the cold air (non-vacuum) pass-through and I will connect one of them to the PCV vent on the passenger side valve cover.Be wary of the throttle body ports. Be sure you TB is compatible with your intake via all of the ports on the mounting surfaces line up. If any of them don't, then you will not be able to get this to run correctly. Very easy to check. Any additional vacuum ports can be capped. But it is ultra-critical to make sure that you have the engine breathing through those ports, implying you can't plug ALL of them off. If you do, then it will be applying vacuum to things that aren't supposed to be.

Regarding the bolt holes in the crank - yes they are pass through and blue loctite or teflon sealer needed. If somehow you have one leak, it will be minor. I put loctite on them and have never had an issue. And I actually torque those.

I think I'm good with this intake and the DBC throttle body. I appear to have a redundant hose barb for the PCV vent. I'll use whichever looks better routing.

If you notice anything odd, I would much appreciate feedback. You've been very helpful.

Attachments

Close to, but not pressurized on the bolts like a SBC head bolt.The rear main bearing is spraying oil right at this location i believe

Looks good to me. Confirm that the gasket (o-ring) is contacting the DBC TB on all flat surfaces and you'll be fine.Since you are being helpful, I have uploaded a picture of intake manifold and original and swapped throttle body. It appears that the DBW uses the butterfly to control idle air whereas the old LS1 DBC from F-body uses IAC and has a hole in the butterfly plate. The IAC port matches up to the vacuum and the pass-through for cold air PCV vent to passenger side valve cover matches up to the cold air (non-vacuum) pass-through of the truck manifold. It appears I have two hose barbs for the cold air (non-vacuum) pass-through and I will connect one of them to the PCV vent on the passenger side valve cover.

I think I'm good with this intake and the DBC throttle body. I appear to have a redundant hose barb for the PCV vent. I'll use whichever looks better routing.

If you notice anything odd, I would much appreciate feedback. You've been very helpful.

You can plug whichever one you don't want to use with something like these :

These kits can be had cheap or use a piece of vacuum line on it with a 5/16" bolt sticking out of it. I don't think you're a 'bolt in the vacuum line' kinda guy though.

Am I right or wrong?

Now you know all you need to know about me

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 73

- Replies

- 3

- Views

- 110

- Replies

- 13

- Views

- 393

- Replies

- 2

- Views

- 155

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.