Your cage nuts in those locations are toast. It’s unfortunate but very common. You can buy new cage nuts and weld them in. To do so you will need to access them from the top.I’m sure this has been asked but there is some sort of locking nut welded inside the chassis for the position like 3 and 4 body mounts? I am trying to remove them on my 80 and broke the passengers sides and they fell out thank god but the drivers side are just spinning... anybody know what needs to be repaired. I see there is a body mount kit but it looks like it’s for the trunk only

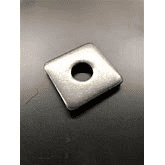

C122 - 1967-74 Camaro, Firebird, Nova, GM X Body; Subframe Body Mount Cage Nut; Each

Reproduction of the original subframe cage nut designed for use with various 1967-74 GM models as listed. This body mount cage nut is manufactured from stamped steel and used to fasten the subframe to the body.