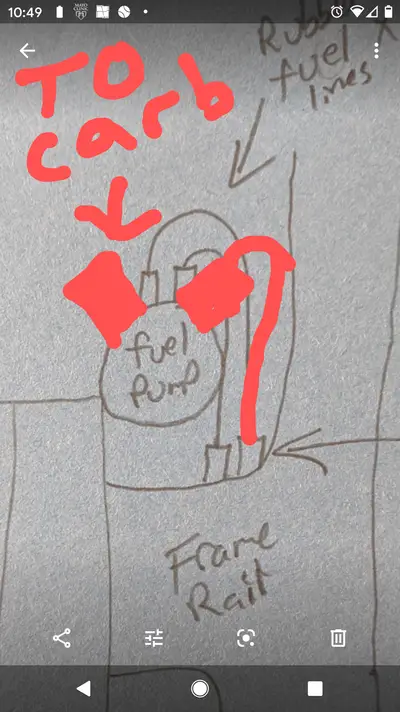

Black fittings on braided stainless are always my favorite. Won't look as nice but you could put a 3/8" barbed fitting in the pump and connect it to the factory line with a PC of 3/8" fuel line and two clamps. Then run the braided hose up to the carb and it would still look good. The inlet and outlet on the Edelbrock pump might be able to be clocked individually because I see there is a gasket in between the two. I could be wrong though

Fuel Line To Fuel Pump Routing

- Thread starter mikester

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Black fittings on braided stainless are always my favorite. Won't look as nice but you could put a 3/8" barbed fitting in the pump and connect it to the factory line with a PC of 3/8" fuel line and two clamps. Then run the braided hose up to the carb and it would still look good. The inlet and outlet on the Edelbrock pump might be able to be clocked individually because I see there is a gasket in between the two. I could be wrong though

They cant be clocked individually.

Are those the factory transmission lines? I want to make new ones and like how those run

Lines came from Inline Tube and theyre for a TH350. Theyre stainless

They cant be clocked individually.

Hmmmmmm, what if you clocked the fuel pump fittings toward the front? Would you have room? Sorry I'm just guessing based on what I know. Just to warn you if you use the Earl's hardline adapter I think you will have to cut the tip of the factory fuel line off. There is a bubble/ or a flare in it to help hold the fuel line on with a clamp and the ferrule on the Earl's fitting needs to slide over smooth unflared tubing.

Attachments

Hmmmmmm, what if you clocked the fuel pump fittings toward the front? Would you have room? Sorry I'm just guessing based on what I know. Just to warn you if you use the Earl's hardline adapter I think you will have to cut the tip of the factory fuel line off. There is a bubble/ or a flare in it to help hold the fuel line on with a clamp and the ferrule on the Earl's fitting needs to slide over smooth unflared tubing.

Im aware of that. Downside is once its cut theres no going back. Im putting the old Carter pump on today to see what I can do before I go out and buy a new one. This is getting to be a pain in the butt.

I don't blame you, there's not much to work with there and once it's cut there's no going back. What about one of these adapters? Put this on the factory steel line then run AN hose to the pump. Would only need a 2-3" piece of rubber hose

www.summitracing.com

www.summitracing.com

Free Shipping on Orders Over $99 at Summit Racing

Get fast, Free Standard Shipping on orders over Summit Racing Equipment from $99 -- no shipping, handling, or rural fees! Exclusions apply.

- Status

- Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 712

- Replies

- 9

- Views

- 385

- Replies

- 2

- Views

- 363

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.