Got some photos of the frame for the experts here. Need an honest word of advice. Patch the frame or replace the frame rails, and how much is that gonna cost me as I do not have the means to do it my self. I mean, I could rent a welder and tools and learn to do it in my driveway but.. that's unlikely.

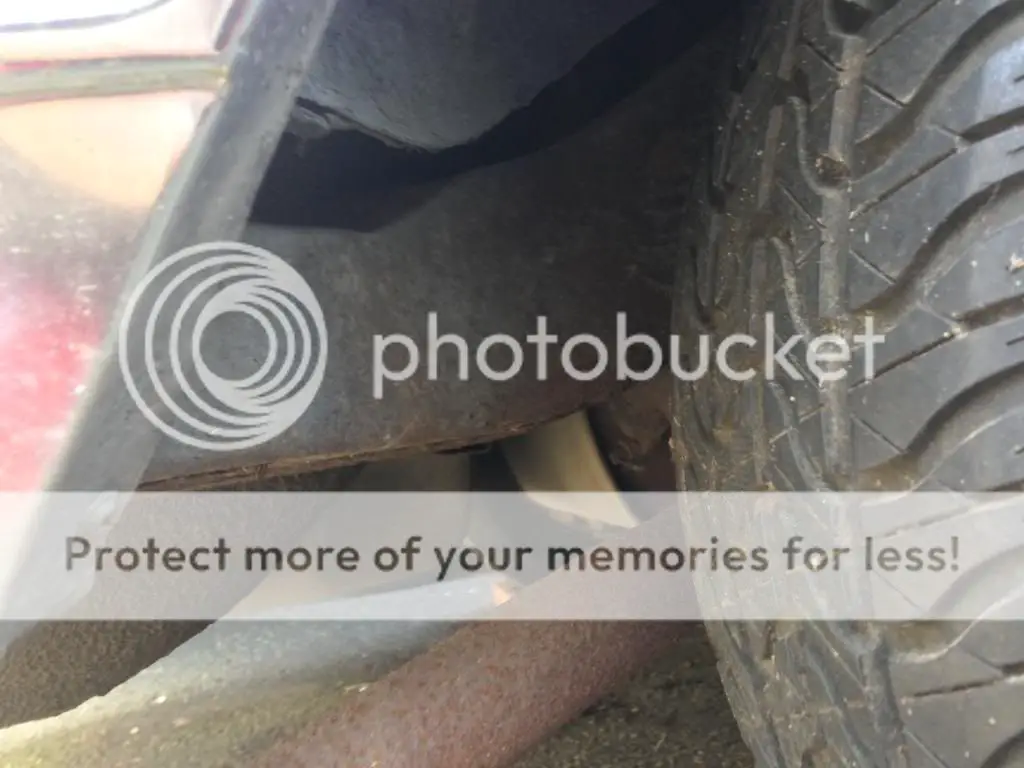

The frame, left side

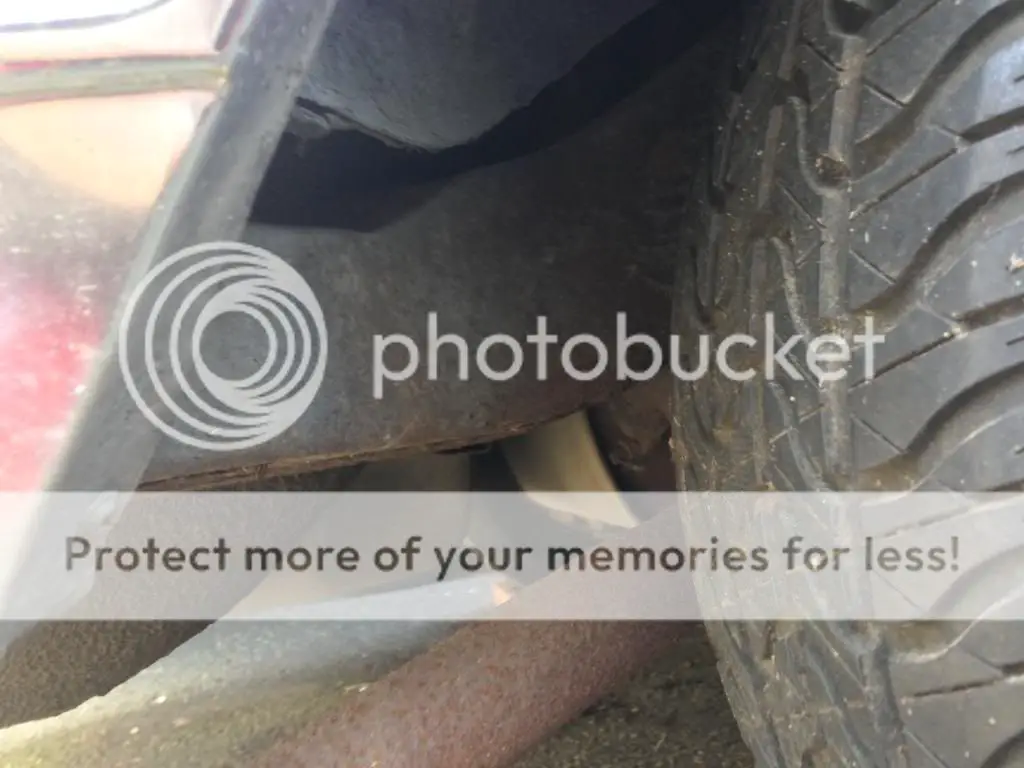

the frame, right side behind the wheel

Right side, infront of the wheel, and the rest of the frame looks like this

some more photos of the car

and some more pics here http://s1281.photobucket.com/user/theevolutionman/library/Monte Carlo?sort=3&page=1

I got an offer for her for 750 with no engine, but I'd rather fix that frame and enjoy the ride my self. Let me know what you think it will cost me to keep this lovely clean gbody on the road and which method is best to take. cheers!

I got an offer for her for 750 with no engine, but I'd rather fix that frame and enjoy the ride my self. Let me know what you think it will cost me to keep this lovely clean gbody on the road and which method is best to take. cheers!

The frame, left side

the frame, right side behind the wheel

Right side, infront of the wheel, and the rest of the frame looks like this

some more photos of the car

and some more pics here http://s1281.photobucket.com/user/theevolutionman/library/Monte Carlo?sort=3&page=1

I got an offer for her for 750 with no engine, but I'd rather fix that frame and enjoy the ride my self. Let me know what you think it will cost me to keep this lovely clean gbody on the road and which method is best to take. cheers!

I got an offer for her for 750 with no engine, but I'd rather fix that frame and enjoy the ride my self. Let me know what you think it will cost me to keep this lovely clean gbody on the road and which method is best to take. cheers!