I rebuilt my GN axle with a 30-spline Auburn and matching Moser axles. I saved the stock axle shafts to adapt my original 7.5 to use a Torsen limited slip I found in a boneyard axle. I had to turn the ends down a bit to make them fit the central block in the Torsen.

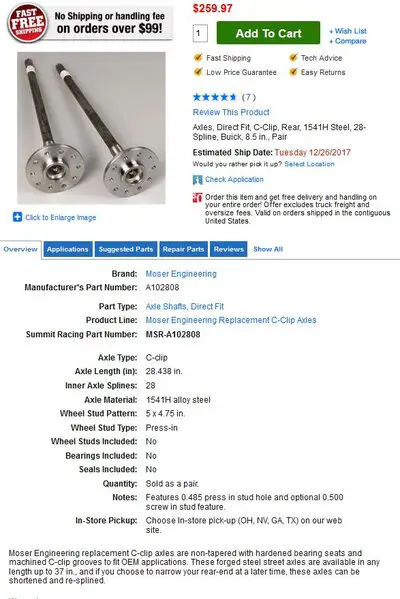

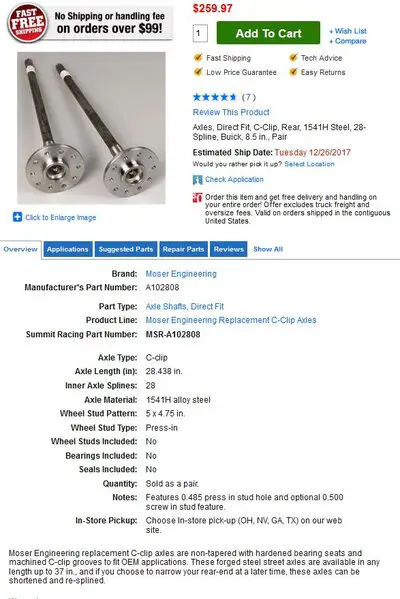

After the doing the machine work, I finally noticed that the bearing surface on one of the axles was done for. I made a snap decision and bought another pair of 8.5 Moser 28-spline axles, but I have decided that they are too good for the contraption I have built. If I change my mind after turning them down to fit, they would be hard to liquidate again.

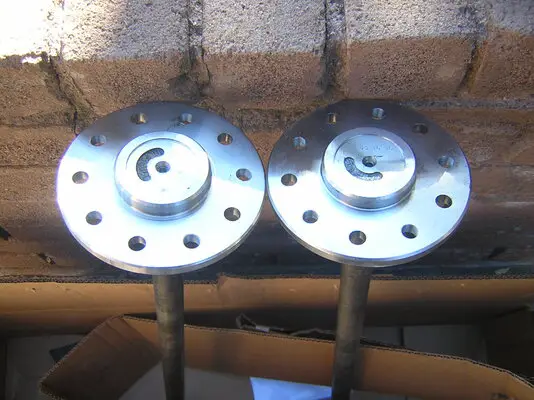

So, I have a $260 pair of uninstalled Moser axles new in the box from Summit. If you can provide a pair of undamaged used GN / HO 28- spline axles, make me an offer for mine. We can split the deal between two interested parties as needed. Please provide photos of your axle shafts, or one good axle if that's what you have.

After the doing the machine work, I finally noticed that the bearing surface on one of the axles was done for. I made a snap decision and bought another pair of 8.5 Moser 28-spline axles, but I have decided that they are too good for the contraption I have built. If I change my mind after turning them down to fit, they would be hard to liquidate again.

So, I have a $260 pair of uninstalled Moser axles new in the box from Summit. If you can provide a pair of undamaged used GN / HO 28- spline axles, make me an offer for mine. We can split the deal between two interested parties as needed. Please provide photos of your axle shafts, or one good axle if that's what you have.