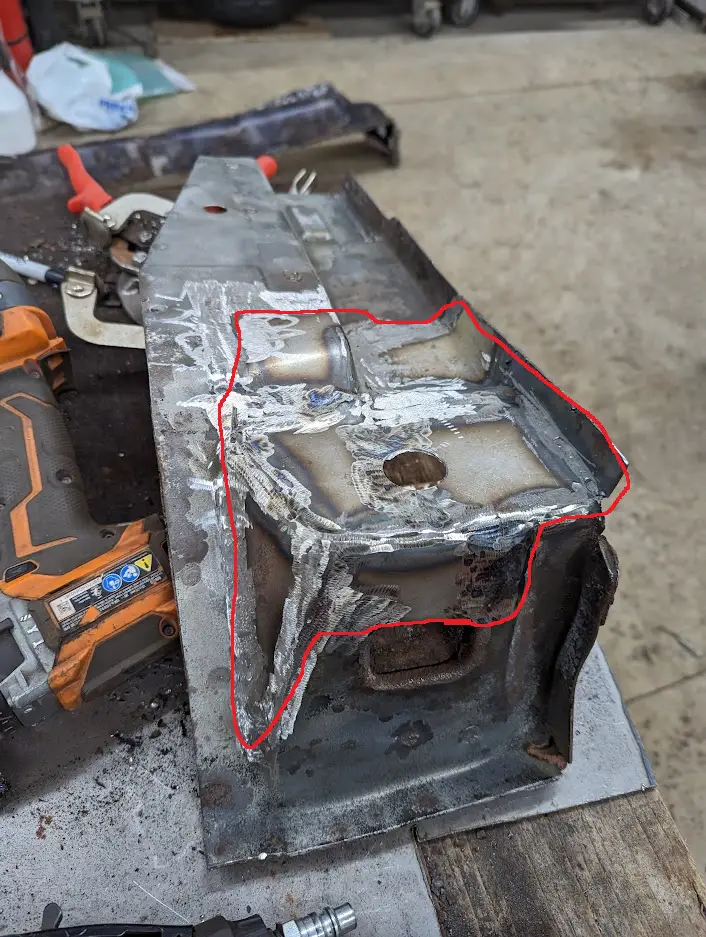

Hello All Im doing a 87 T type restoration/race car. I have now made money from this car parting it out lol I just want the frame and Shell anywayz. Floor is bad. Real bad.

As you can see Ive cut Majority of it out. outer rockers shot inner rockers rough. Etc. Heres my Idea I bought a cutlass shell

Lopped the floor off at the bottom of the A and B Pillars all the way up into the trunk area

Im cleaning it up for Primer now. Now Obviously I would trim the rest of the Firewall off of the floor here by taking spot welds out here

And here

At the back seat seat back

I have rust on the body at the bottom of the A pillar and my Front of rear wheel oppening. So I have patch panels for A pillar and B pillar and the patch panels for the Front of rear wheels.

Now for the fatty question. Well Two big ones. Im going to try to attempt to remove the bottoms of the pillars off the inner rocker/ floor extensions. Off the donor floor. May or MAY NOT! remove the outer rocker from the donor floor. And do the same to the body except leave enough material to work the patch panels for the pillars to be able to fit of course.

I think the inner rocker comes all the way up and spot welds to the back of the B pillar here

And somehow attatches to the A pillar here i would have to look again.

I WONDER?!?! can I put the whole floor and rockers in from the bottom. Next problem is. And you can see my home made body cart the body is sitting on the rocker pinch welds. Well I have a 2 Post lift. See those braces I taked into the body. Think I could fully weld them up strong and lift the body upper by those bars with my 2 post. Then id be able to get the whole floor and rockers out and the new floor in. Has this ever been done?

As you can see Ive cut Majority of it out. outer rockers shot inner rockers rough. Etc. Heres my Idea I bought a cutlass shell

Lopped the floor off at the bottom of the A and B Pillars all the way up into the trunk area

Im cleaning it up for Primer now. Now Obviously I would trim the rest of the Firewall off of the floor here by taking spot welds out here

And here

At the back seat seat back

I have rust on the body at the bottom of the A pillar and my Front of rear wheel oppening. So I have patch panels for A pillar and B pillar and the patch panels for the Front of rear wheels.

Now for the fatty question. Well Two big ones. Im going to try to attempt to remove the bottoms of the pillars off the inner rocker/ floor extensions. Off the donor floor. May or MAY NOT! remove the outer rocker from the donor floor. And do the same to the body except leave enough material to work the patch panels for the pillars to be able to fit of course.

I think the inner rocker comes all the way up and spot welds to the back of the B pillar here

And somehow attatches to the A pillar here i would have to look again.

I WONDER?!?! can I put the whole floor and rockers in from the bottom. Next problem is. And you can see my home made body cart the body is sitting on the rocker pinch welds. Well I have a 2 Post lift. See those braces I taked into the body. Think I could fully weld them up strong and lift the body upper by those bars with my 2 post. Then id be able to get the whole floor and rockers out and the new floor in. Has this ever been done?