Hey All,

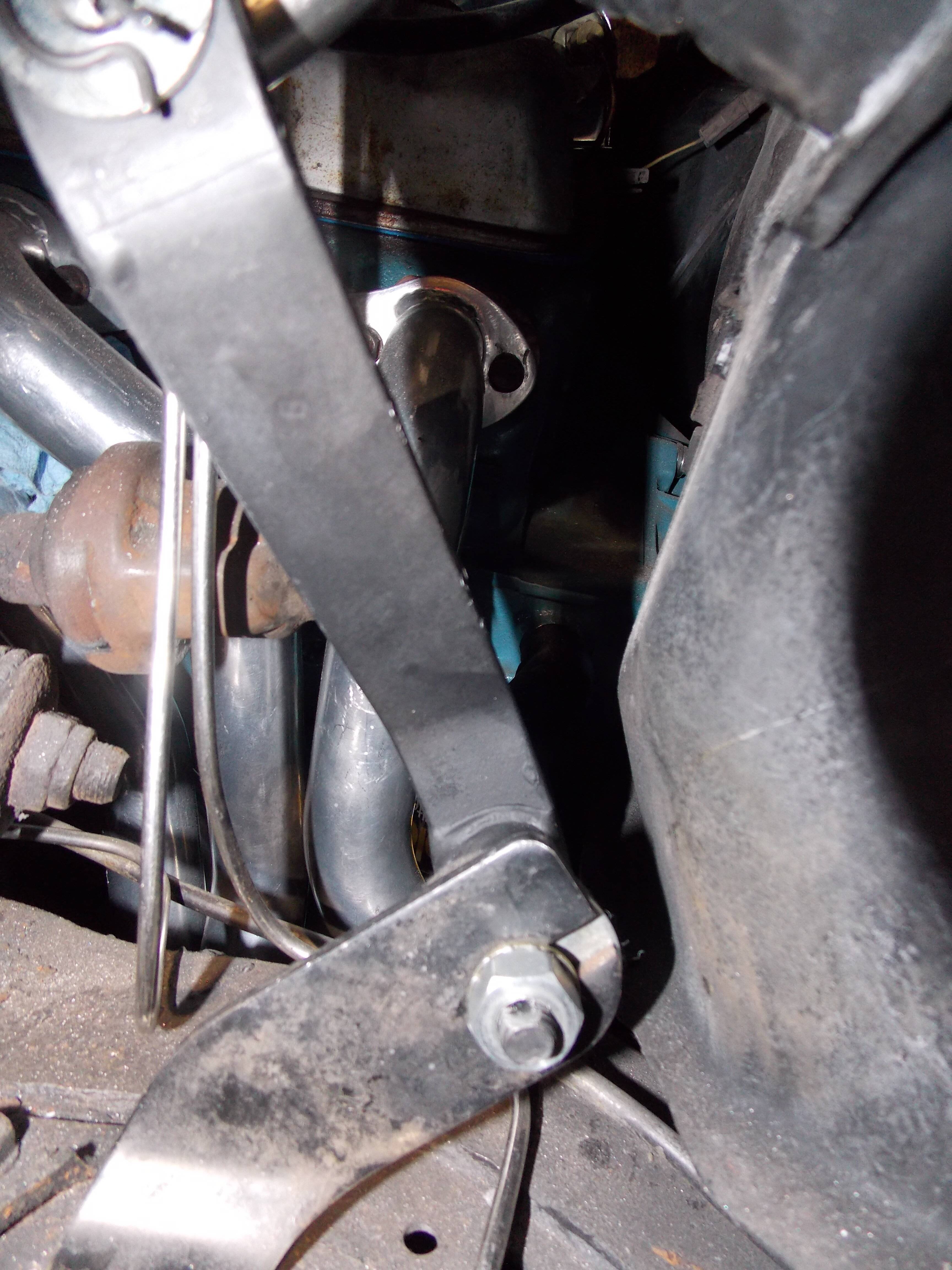

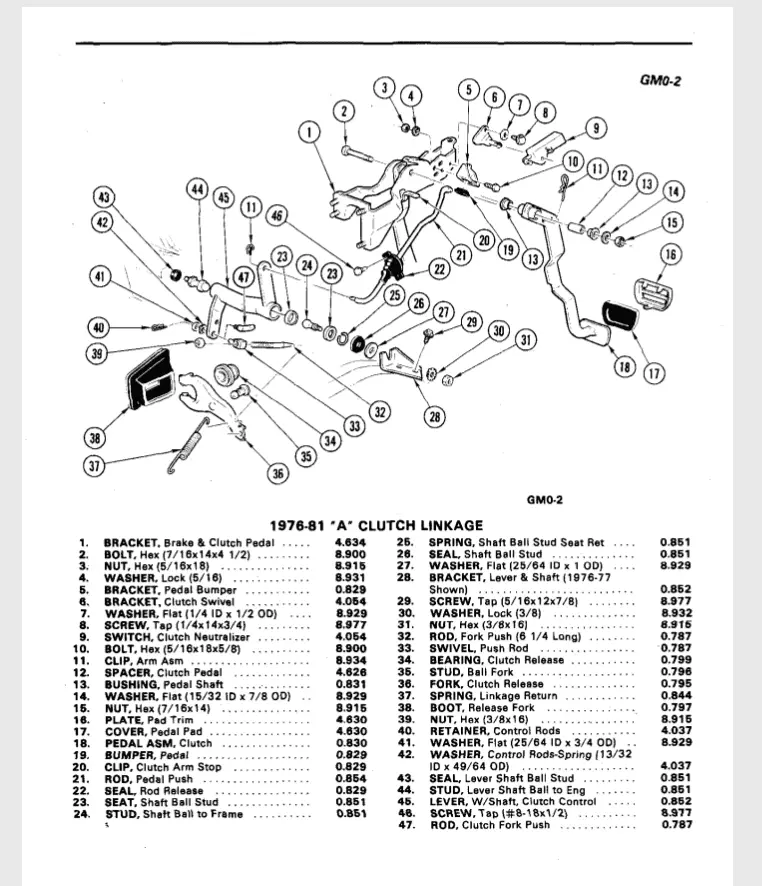

Looking for some help with a manual linkage/clutch pedal install in a 78 malibu originally equipped with a th350. I am using the clutch pedal/linkage kit similar to the OPG kit (see pic). I just need a little help getting started, installing the pedal and where the bracket goes on the frame, the z bar etc. Pics would be helpful! I have scoured the internet and have not been able to find much relevant info. It appears most are asking hydraulic retrofit oriented questions.

PS I have a T-10 I will be mating to a 350. I already have the attached kit (pic), the trans, g body bellhousing, clutch, flywheel etc, I should have just about everything and am ready to get started!

Looking for some help with a manual linkage/clutch pedal install in a 78 malibu originally equipped with a th350. I am using the clutch pedal/linkage kit similar to the OPG kit (see pic). I just need a little help getting started, installing the pedal and where the bracket goes on the frame, the z bar etc. Pics would be helpful! I have scoured the internet and have not been able to find much relevant info. It appears most are asking hydraulic retrofit oriented questions.

PS I have a T-10 I will be mating to a 350. I already have the attached kit (pic), the trans, g body bellhousing, clutch, flywheel etc, I should have just about everything and am ready to get started!