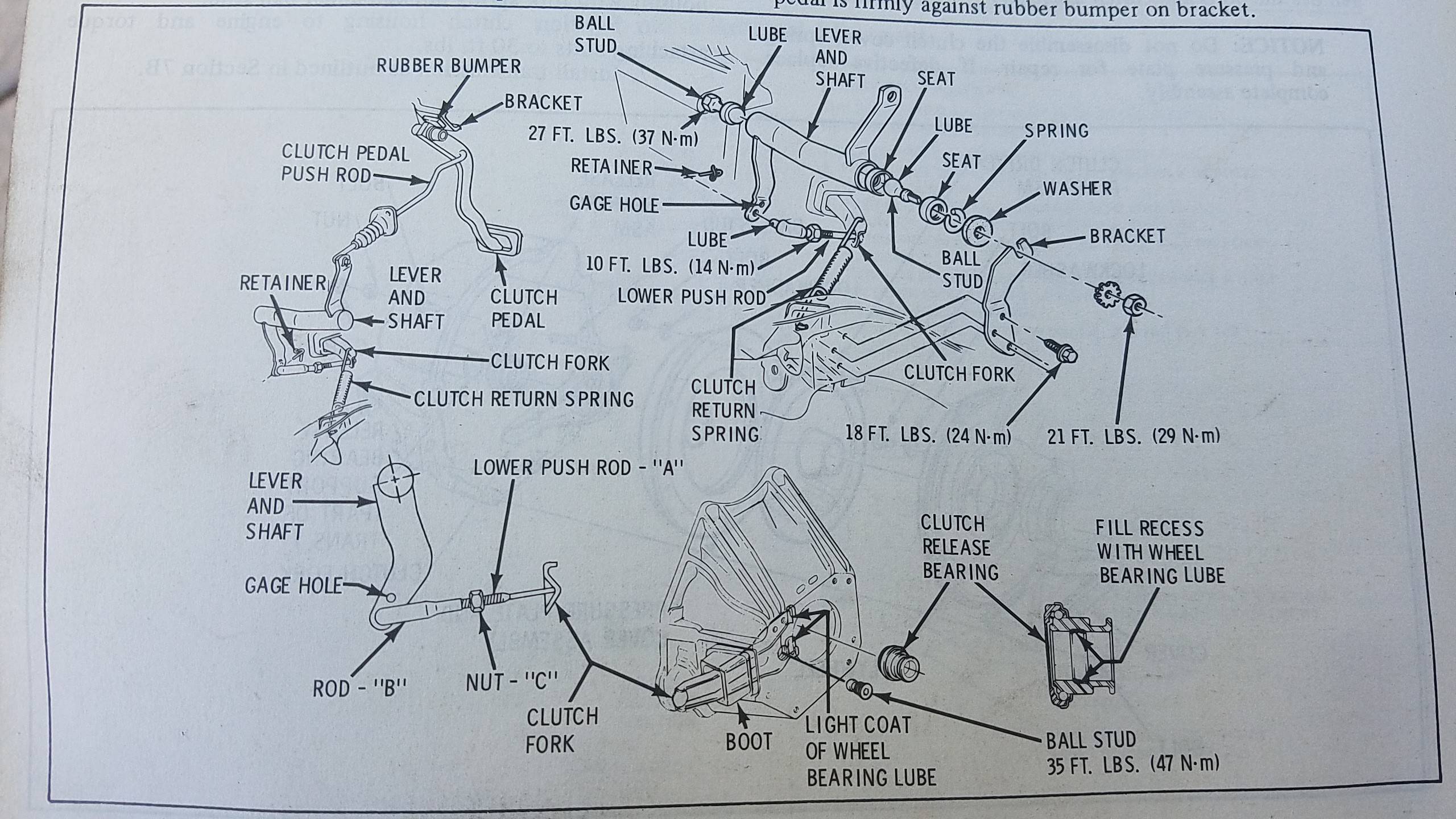

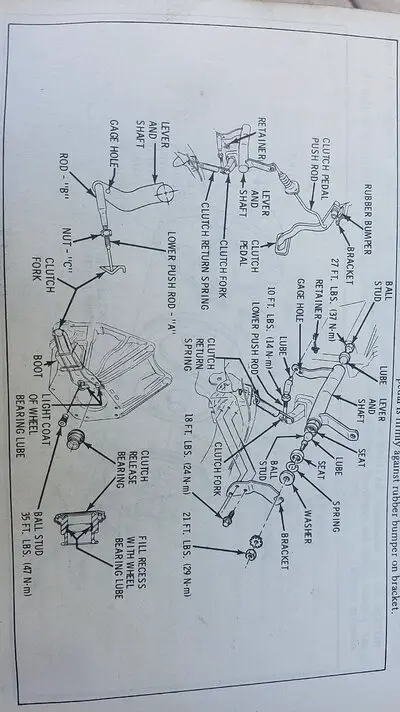

While the parts breakdown pictures for the clutch/brake pedal assembly are useful, perhaps seeing it as working assembly might be of use here

So this first shot is obviously an overview of what the complete pedal assembly more or less ought to look like. This unit is stock, including the pedal pads

These next two shots are detail pics of the bracket. What you are seeing is the mount for the brake light switch and the stop/return bumper for the clutch pedal.

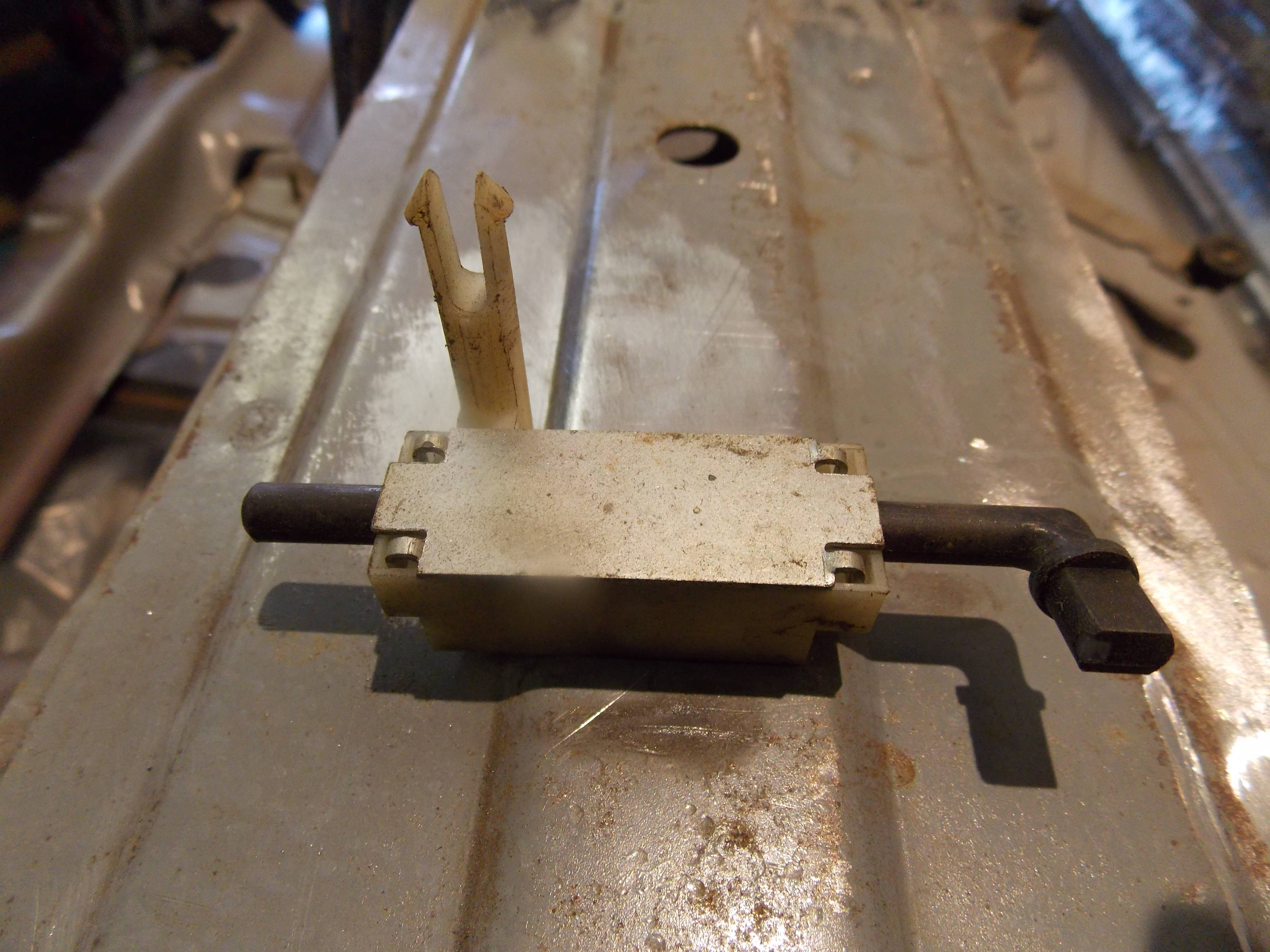

And this is what the factory neutral safety switch more or less looks like. If you refer back to the previous detail shotmof the bumper et al, you can see an ear attached just above the upper bracket mounting hole on the left side. That is the mount point for the switch and the upper hole in the clutch pedal is the mount point for the slide. The switch is not in a fixed position. Instead it "floats" or is free to pivot as needed in order to maintain a linear relationship with the pedal so that the slide can come and go freely

This is just a shot of the mounting hole for the upper rod that connects the pedal to the Z-Bar. When this particular assembly was harvested, the hole for the rod was completely egged out and the rod itself had about half of its pin surface worn away. Totally useless and probably part of the reason the car was sent to the yard. This assembly, like the others I have scored, came originally from a Saudi Chevvy, aka Irani Taxi, or Iraqui taxi, plus a few other impolite sobriques. Long back story to them but the Coles Notes says they were part of deal done by the Saudis with GM for a fleet purchase, ultimate user to be determined. Deal fell through and GM North America consigned the orphans to as many dealers as they could bamboozle into taking them. Over the years I have picked about 5-6 of them and the boz count is supposed to be slightly more than a hundred. Pretty much all gone to rust by now. Anyway, moving on.......

So these last two shots are of the fuse block that resides adjacent to the clutch pedal. The second shot clearly shows the large silver metal bodied relay that I had to move from the original location at three o'clock on the fuse block to its current location at six o0clock. I think the second shot is more clear in terms of the amount of distance that now exists between the fuses and the clutch pedal. You have to look real close and squint a little to see the two lugs that act as mounts for the plug in for that relay. They appear in multiple locations around the perimeter of the block which is sort of an indication that GM had allowed for the probability that the fuse block would be a common source item used across multiple vehicles and that some kind of adaptability needed to be built in.

Here endith the show and tell. Hope these help the cause.

Nick

I also got tired of replacing the upper clutch pedal push rod which wears out fast at the contact points. I sprung for the spherical ball end rod set. MUCH stouter and they don't wear out like the stock rod.

I also got tired of replacing the upper clutch pedal push rod which wears out fast at the contact points. I sprung for the spherical ball end rod set. MUCH stouter and they don't wear out like the stock rod.