I recently purchased a bellhousing, t50 dogleg 5 speed, drive shaft, and clutch fork that were originally behind a 260 in a 78' cutlass (later put in an el camino) for 125$. Decided I couldn't go wrong even if the transmission was junk. This will be my build thread filled with plenty of trial and error, and for the first month or so will be collecting and research. I know I will need a conversion pilot bearing, and have already sourced several. I also have access to a machine shop to machine the shaft on the transmission.

I have a few questions

Does anyone have a source for a reasonably priced oldsmobile flywheel? Hoping to find one at an upcoming swap meet, have had no such luck find a basic replacement one online. Also, what would be the proper size/tooth count for the flywheel?

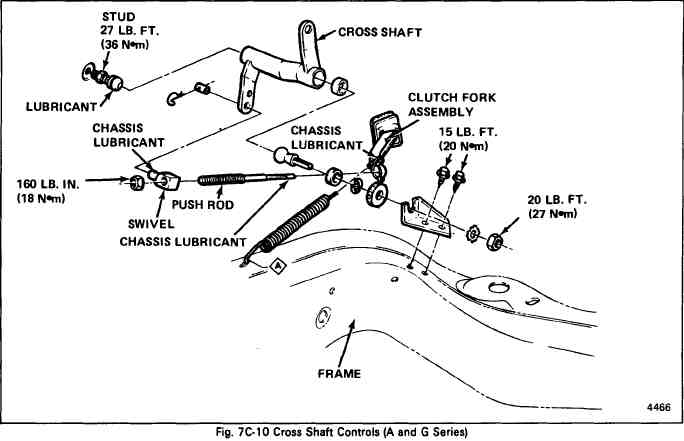

I know the boss for the z-bar ballstud is cast into the 307 block, but is it tapped or even drilled? If not, is there any possibility tapping it in the car?

The t50 is a weaker transmission, but i'm not too concerned about it behind my 307. I'm more concerned about finding parts for it. Could I swap in a t5/saginaw/t10 at a later date and not worry about major changes in mounting or hole location in the transmission hump? Will all these transmissions also bolt to my bellhousing?

Like I said, I have access to a basic machine shop (lathes, milling machines, cnc's, etc) and also have some welding skills. Any input would be greatly appreciated. Hopefully have some pictures by friday.

Thanks for any help.

-Mike

I have a few questions

Does anyone have a source for a reasonably priced oldsmobile flywheel? Hoping to find one at an upcoming swap meet, have had no such luck find a basic replacement one online. Also, what would be the proper size/tooth count for the flywheel?

I know the boss for the z-bar ballstud is cast into the 307 block, but is it tapped or even drilled? If not, is there any possibility tapping it in the car?

The t50 is a weaker transmission, but i'm not too concerned about it behind my 307. I'm more concerned about finding parts for it. Could I swap in a t5/saginaw/t10 at a later date and not worry about major changes in mounting or hole location in the transmission hump? Will all these transmissions also bolt to my bellhousing?

Like I said, I have access to a basic machine shop (lathes, milling machines, cnc's, etc) and also have some welding skills. Any input would be greatly appreciated. Hopefully have some pictures by friday.

Thanks for any help.

-Mike