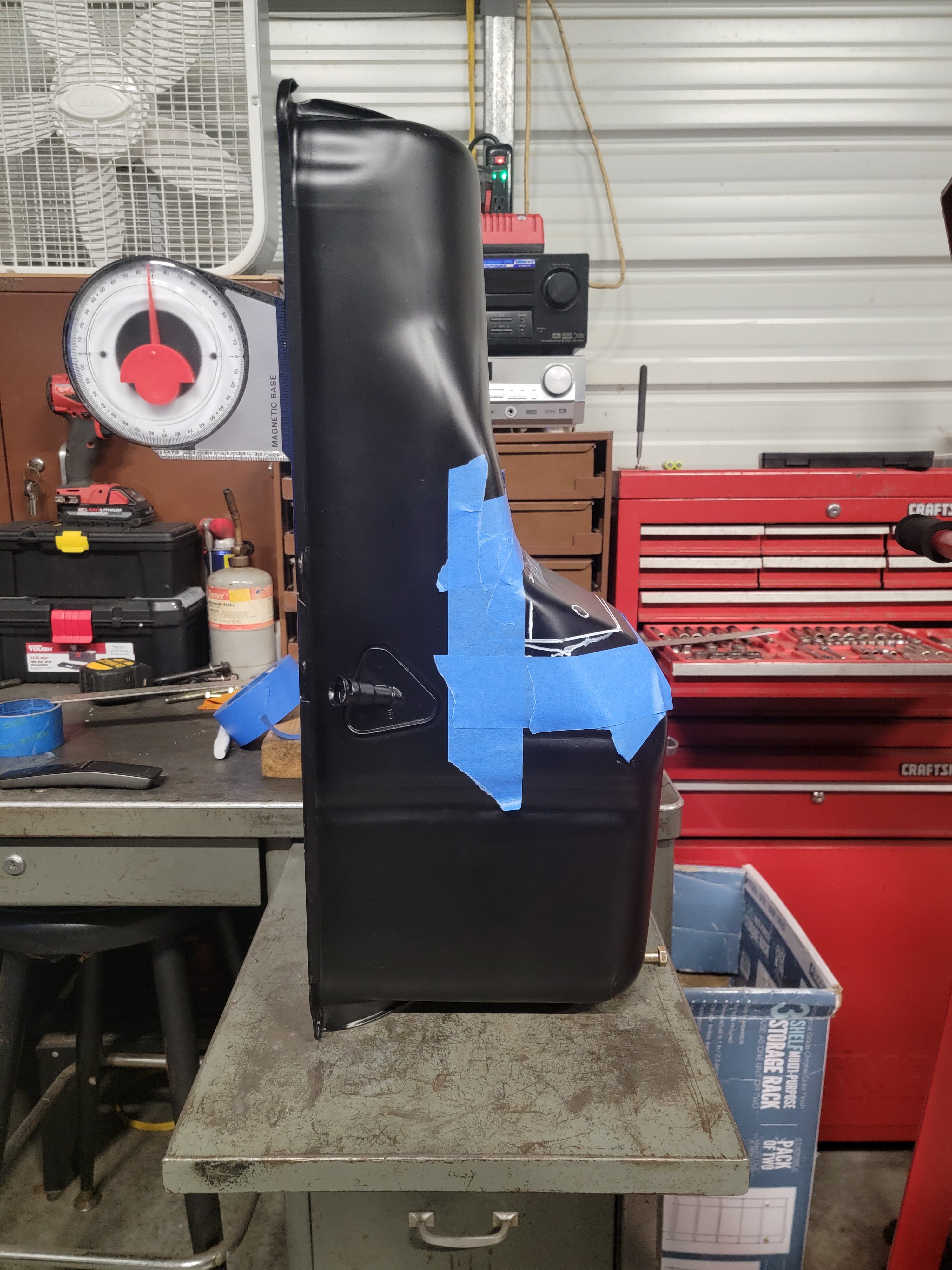

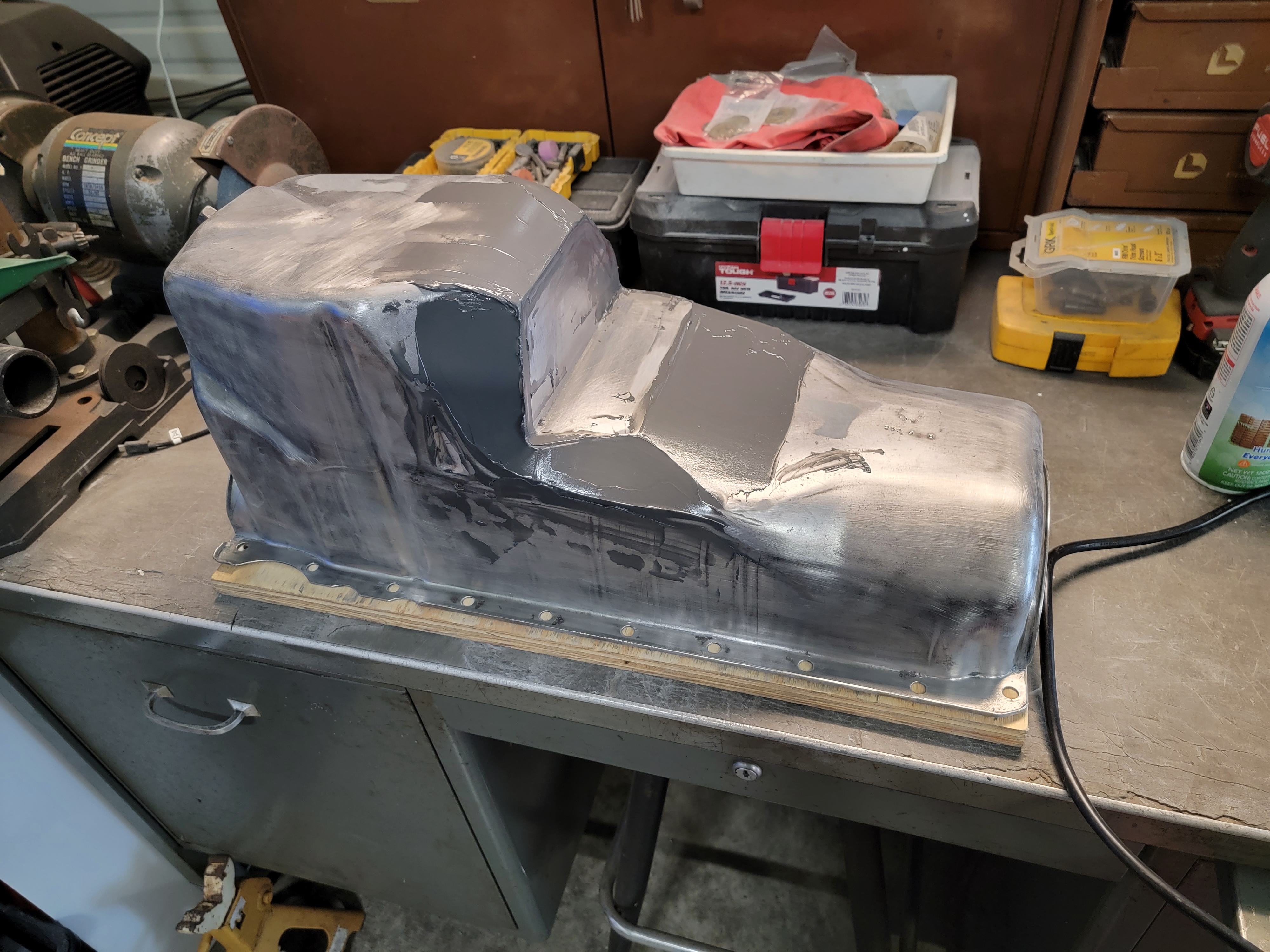

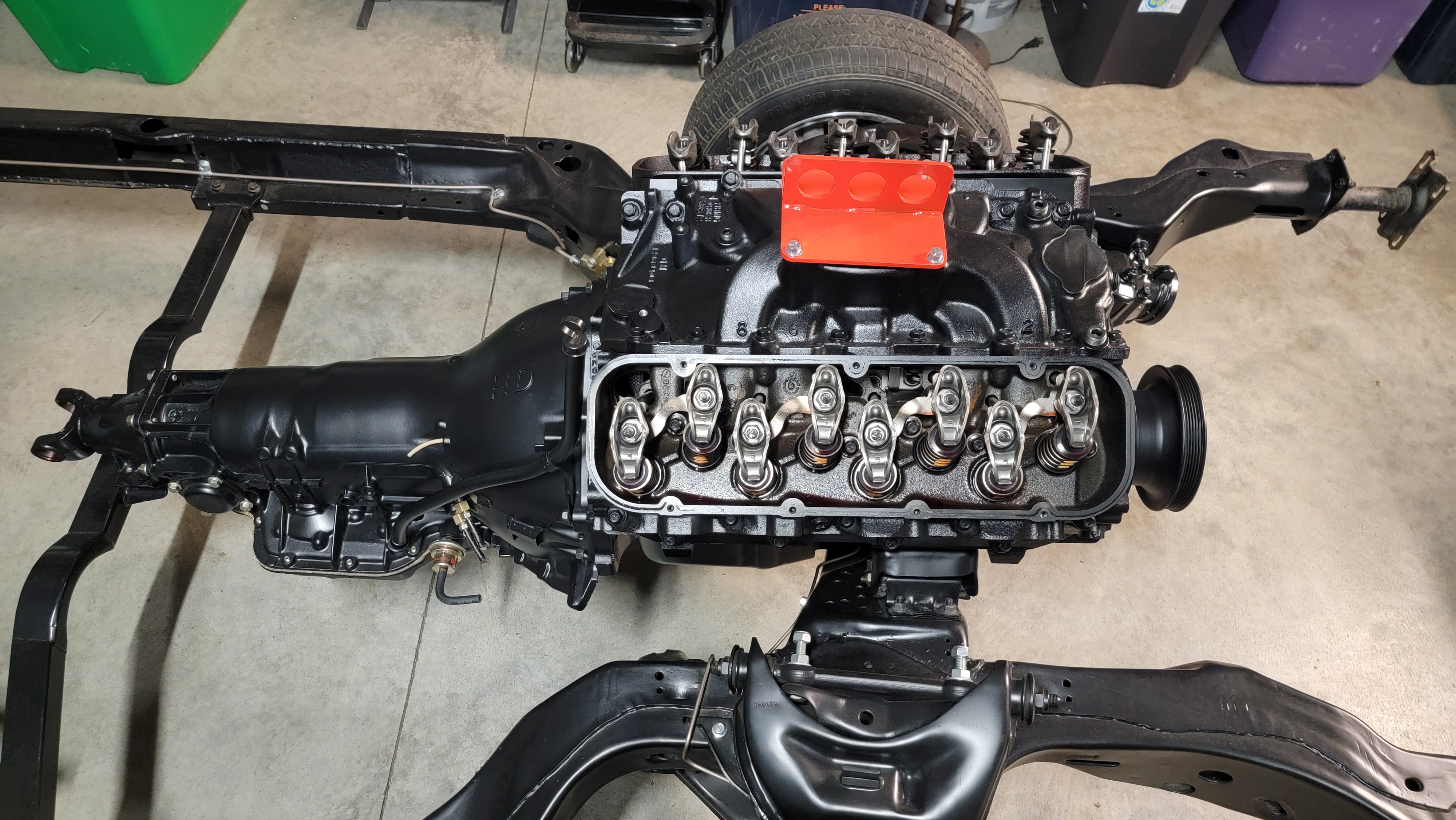

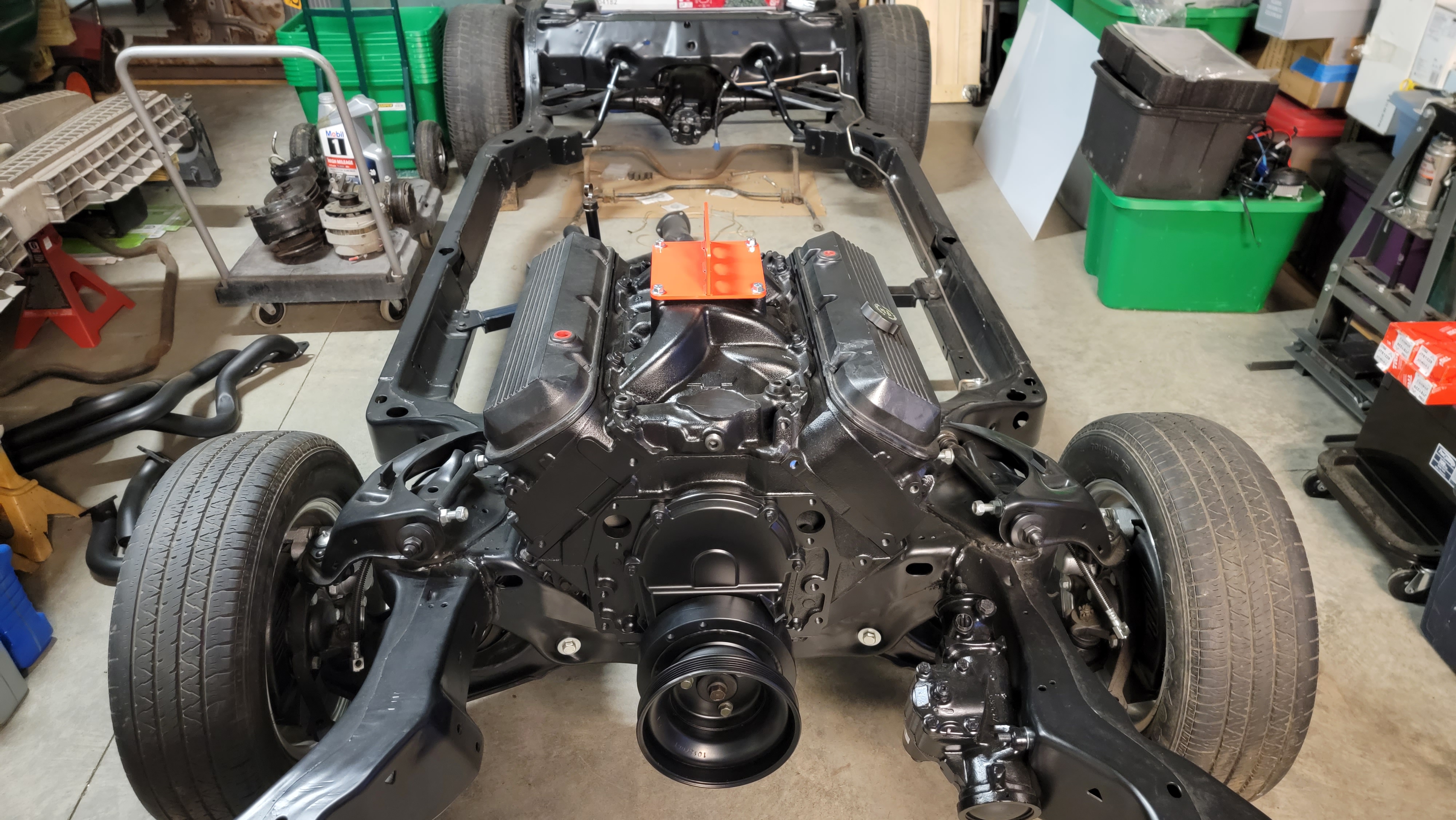

When getting ready to finally install the engine for good, I ran into a clearance issue with the stock Gen VI oil pan. It was hitting the crossmember pretty good.

I don't know how I missed this with the earlier mock up. There are quite a few budget pans that would work with the Mark IV big blocks, but the Gen V/VI ones were a bit pricey and then a new pickup and dipstick is in order. Also, most have kick outs that would then give me header clearance issues.

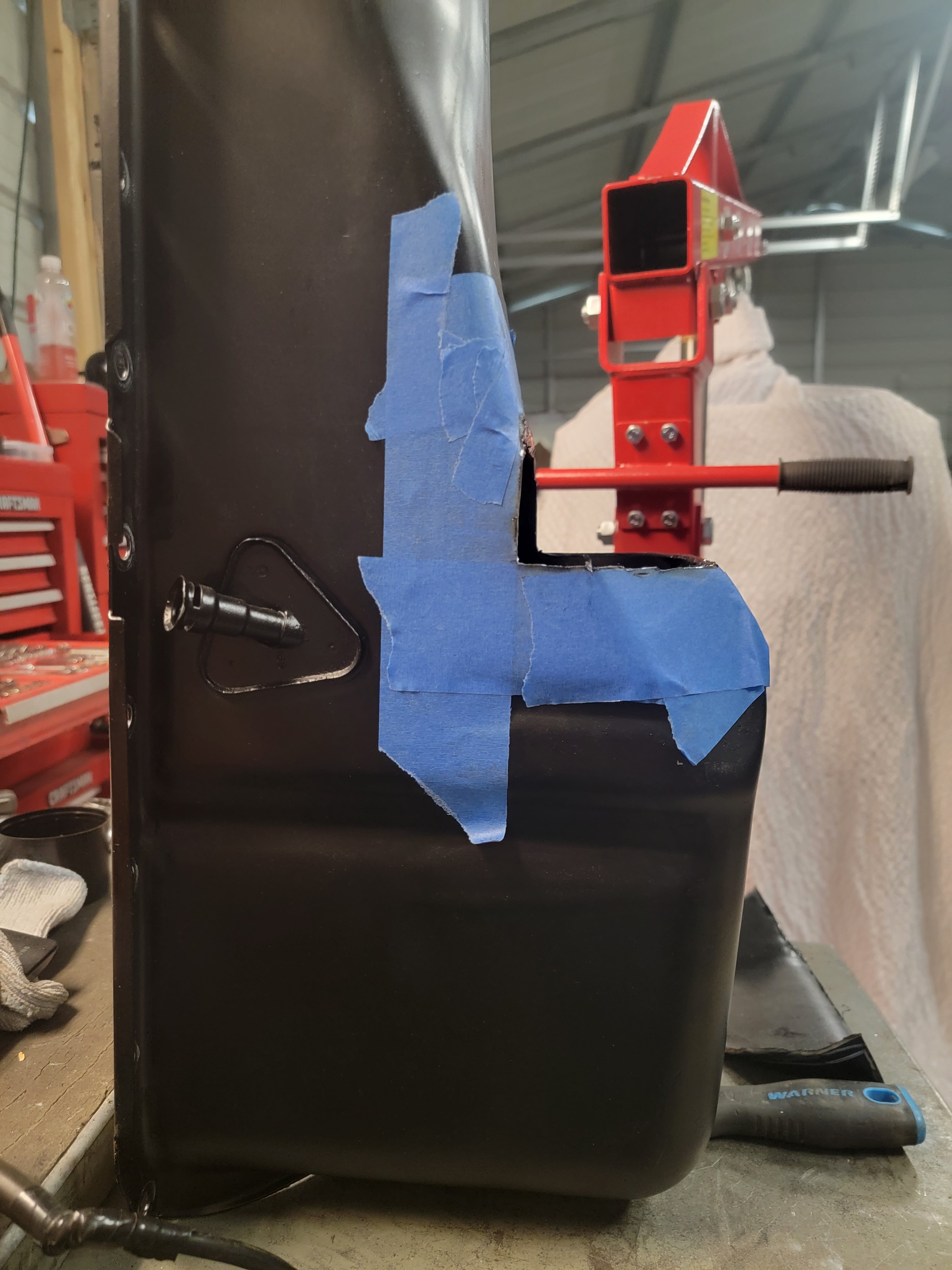

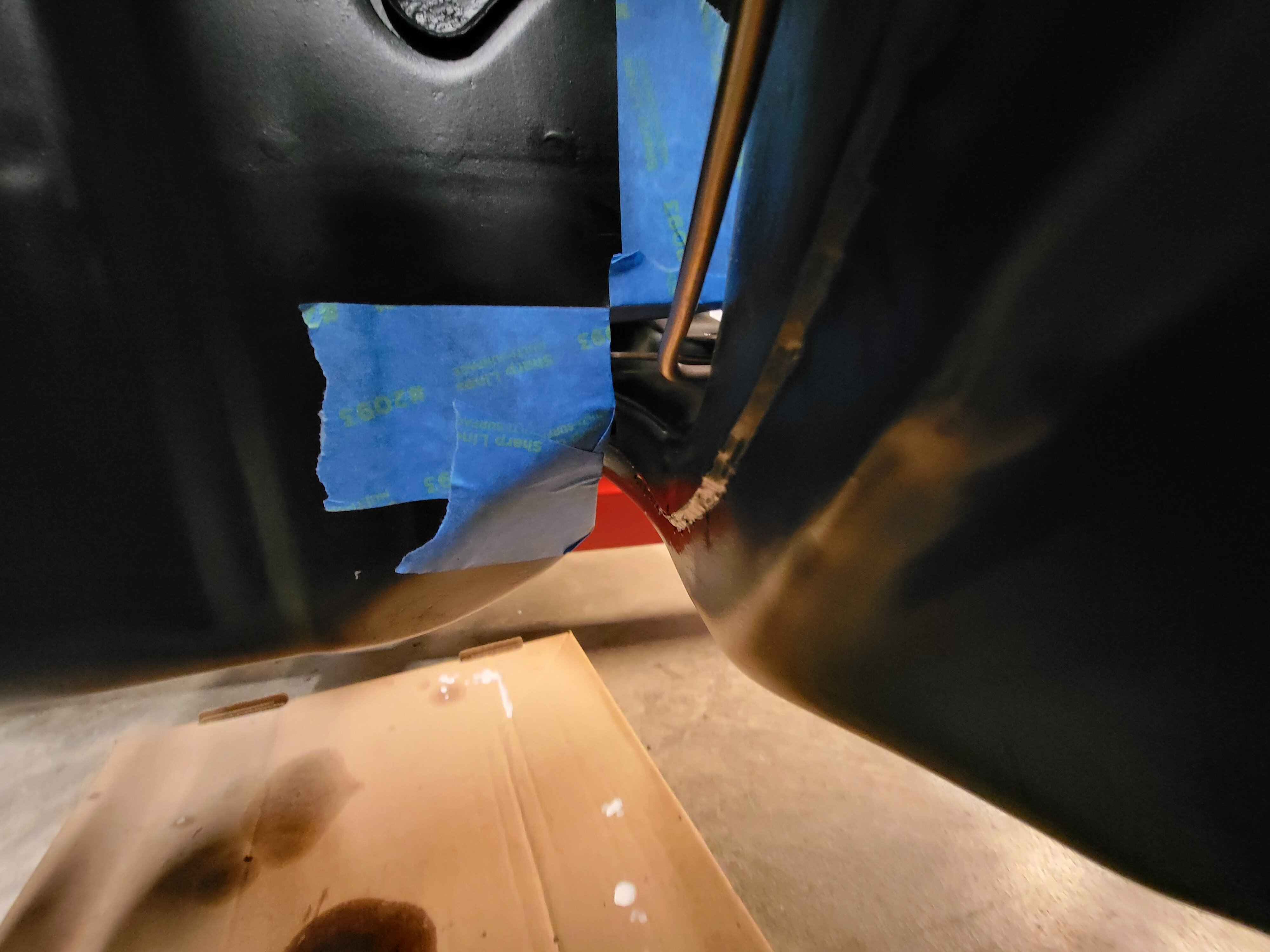

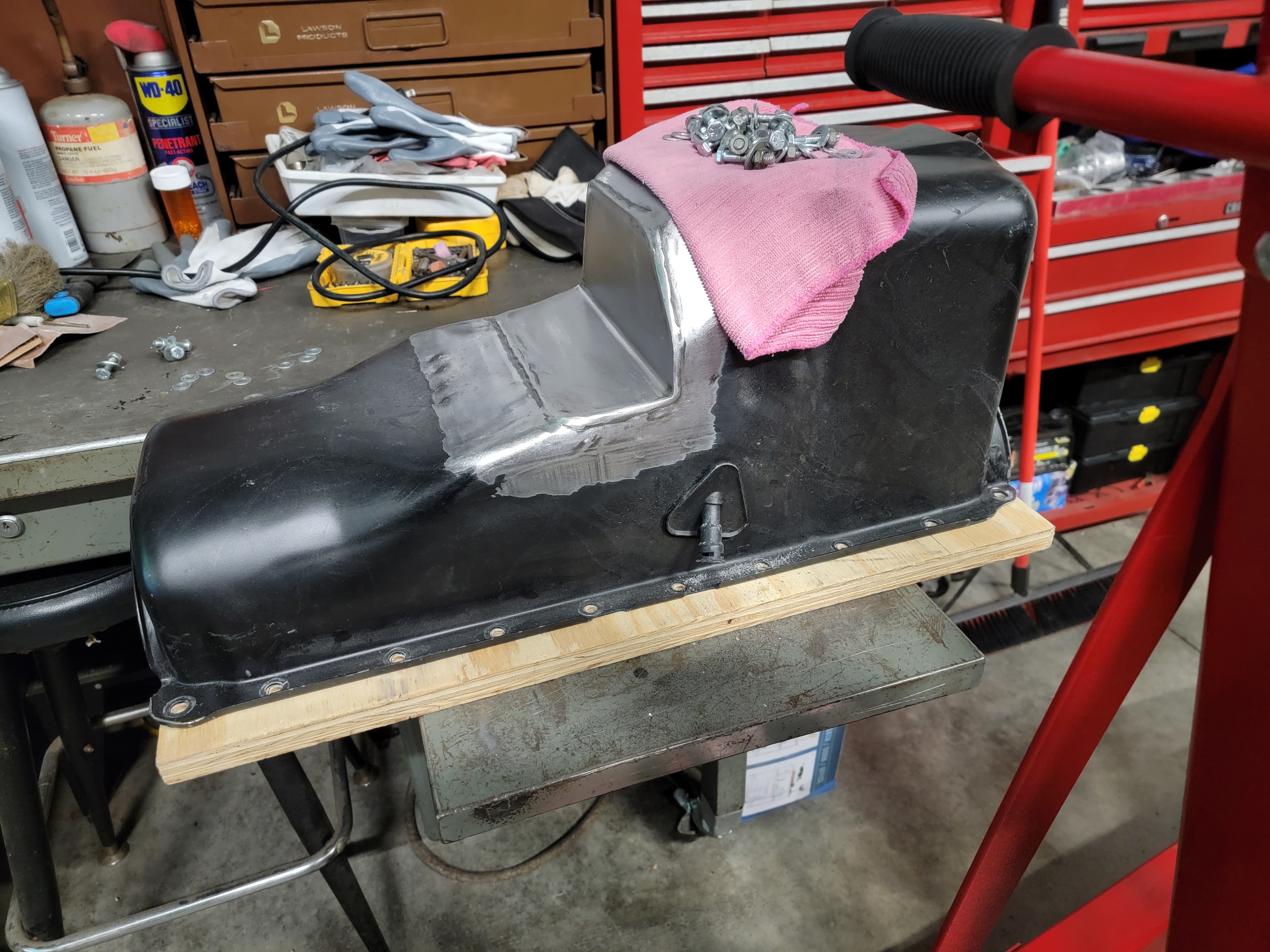

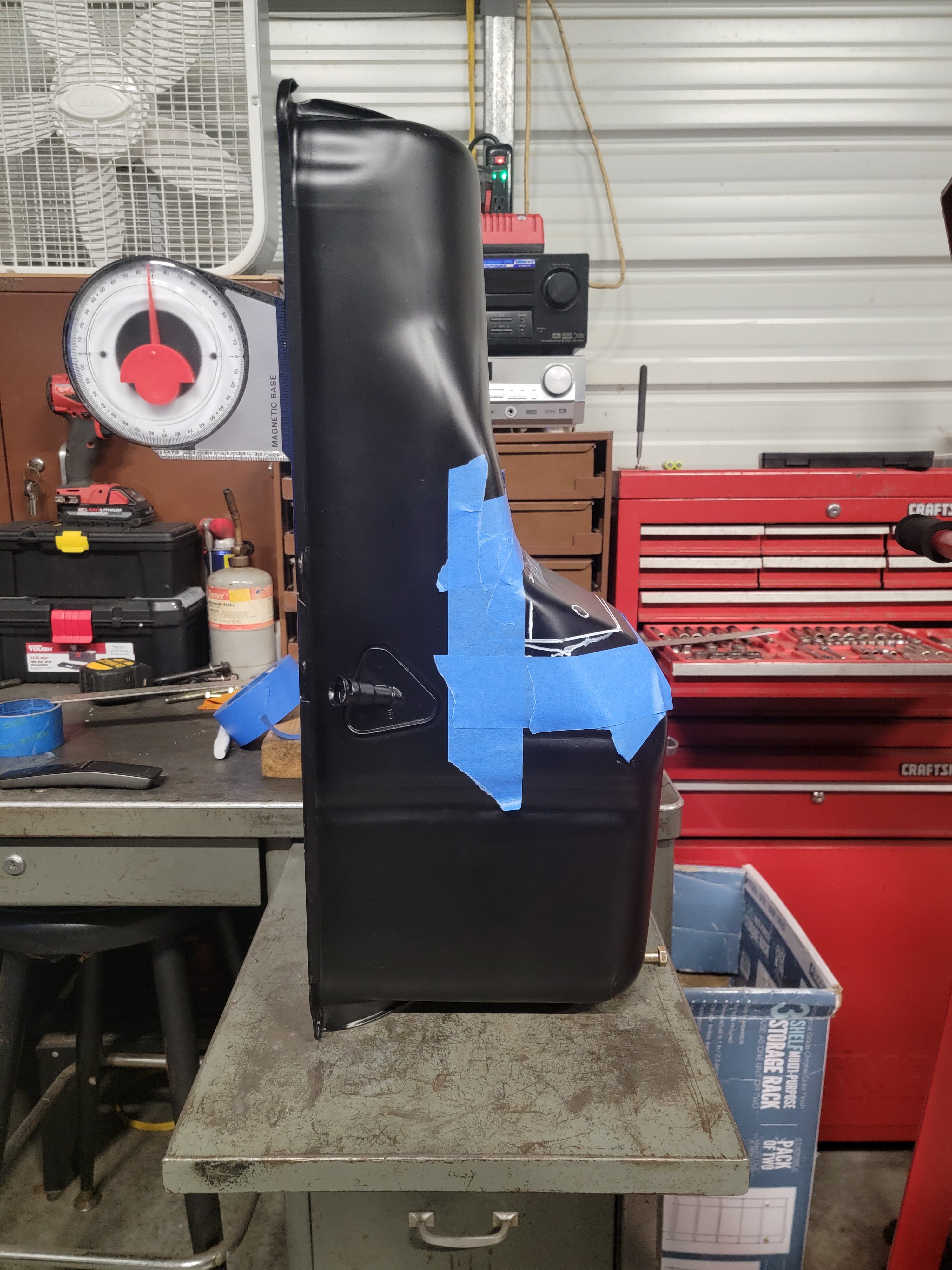

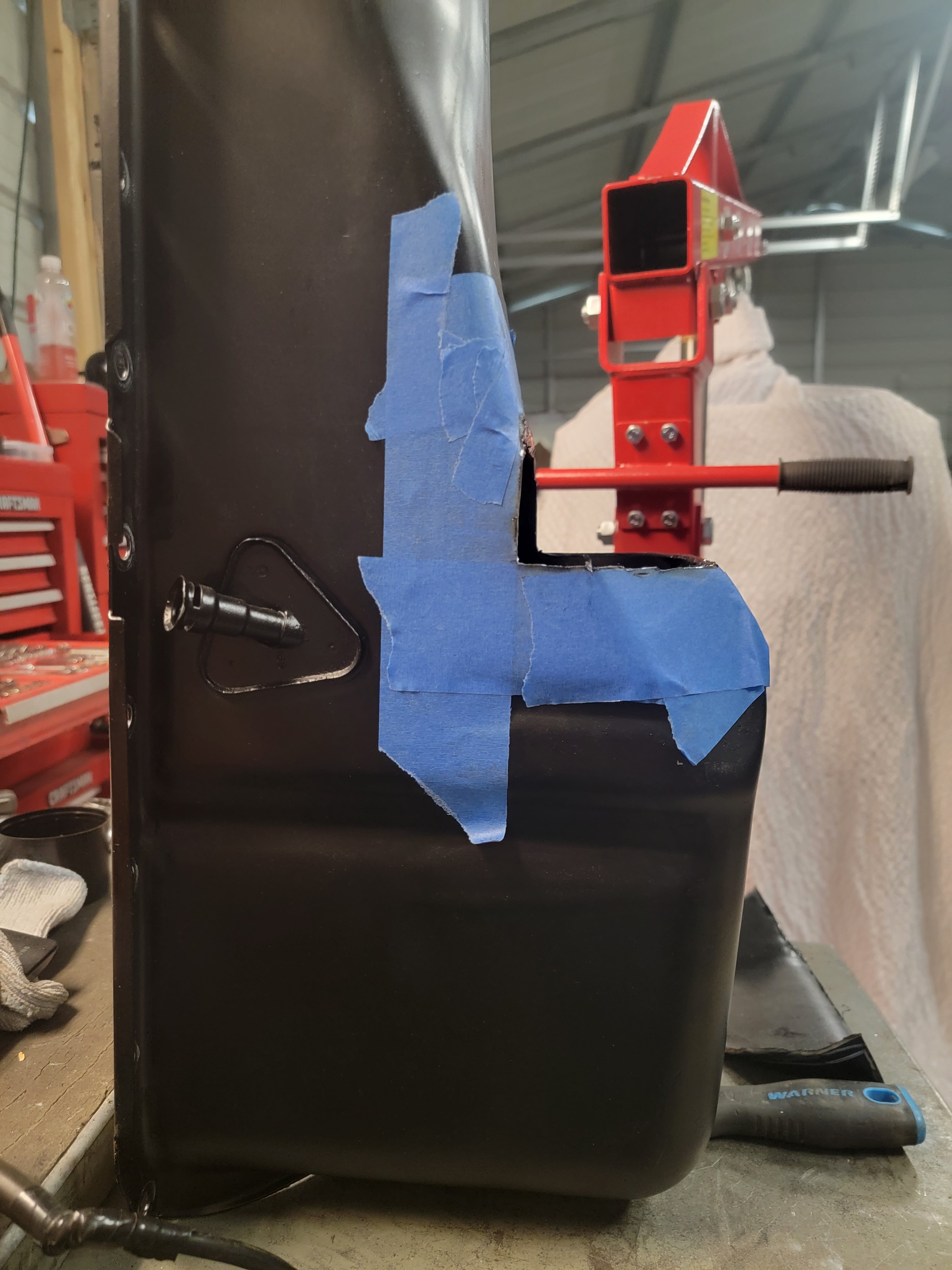

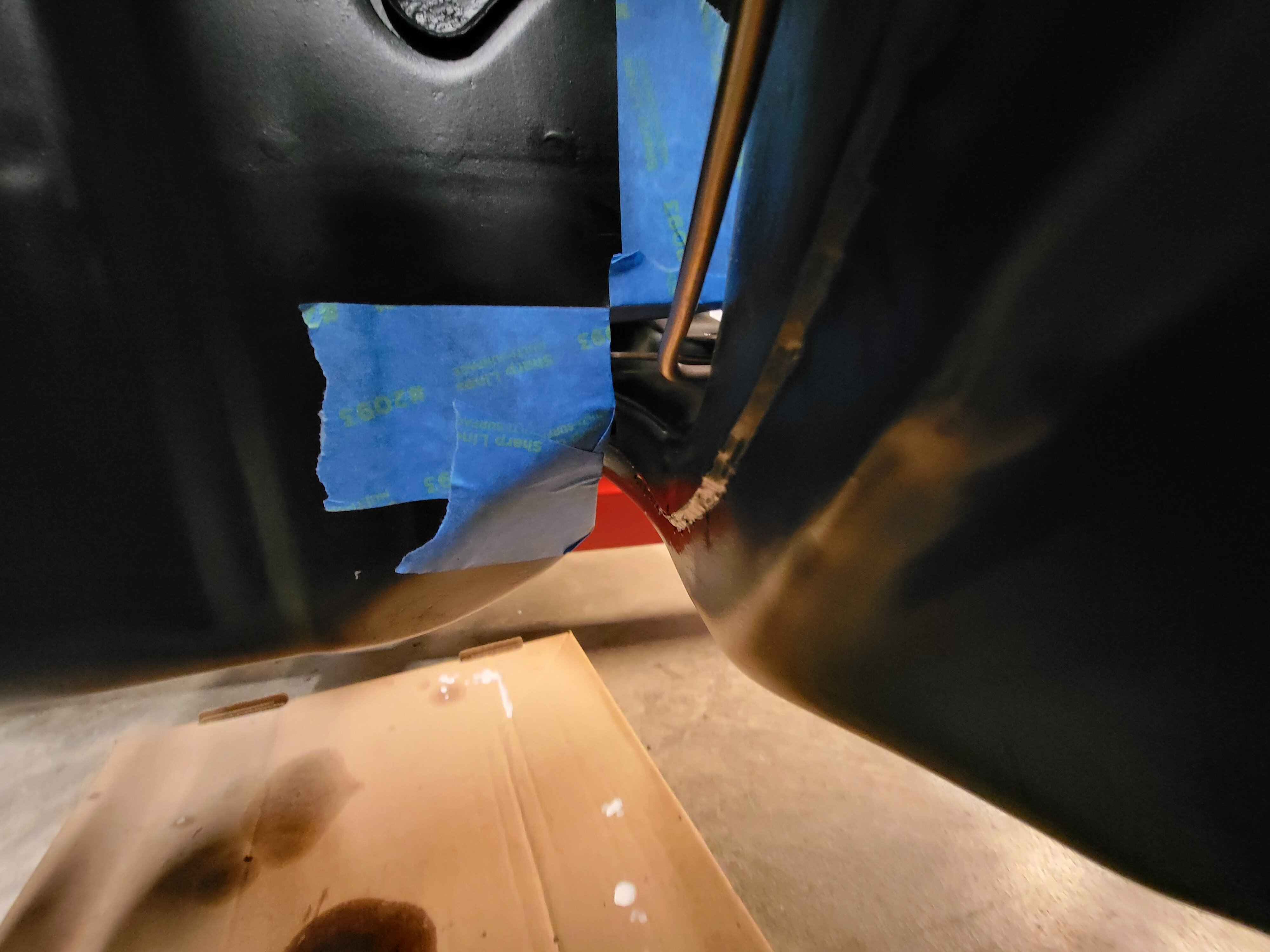

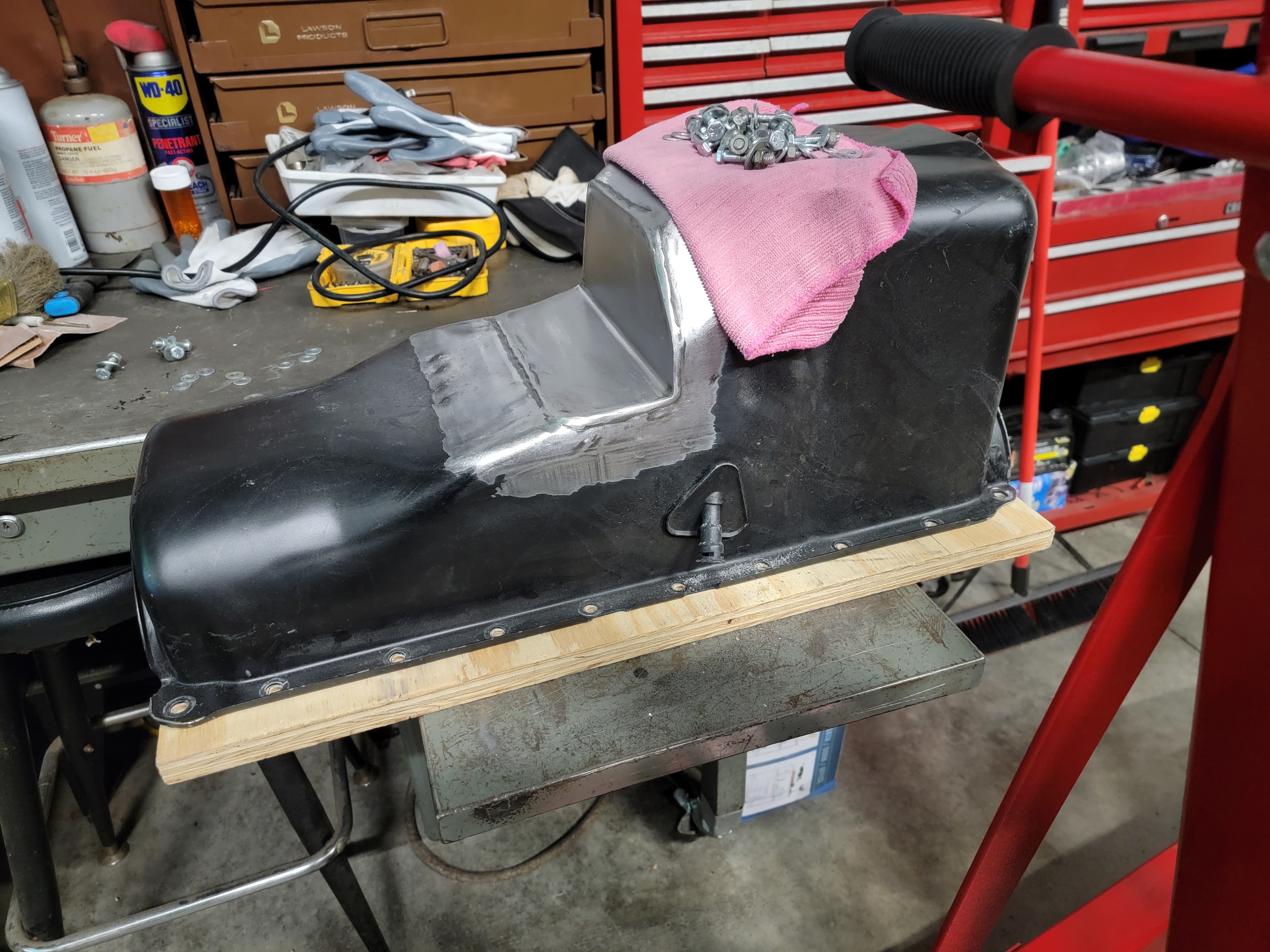

I decided to modify the stock pan. Cut out the offending area then brought it to a local welder who welds tanks and had him leak test it as well for $100. He completely bolted it down to a 3/4" piece of plywood so it wouldn't distort.

I don't know how I missed this with the earlier mock up. There are quite a few budget pans that would work with the Mark IV big blocks, but the Gen V/VI ones were a bit pricey and then a new pickup and dipstick is in order. Also, most have kick outs that would then give me header clearance issues.

I decided to modify the stock pan. Cut out the offending area then brought it to a local welder who welds tanks and had him leak test it as well for $100. He completely bolted it down to a 3/4" piece of plywood so it wouldn't distort.