I have discovered that installing the 8.8 without a lift or when on the ground without someone to help is almost difficult.

Progress though. Nothing pretty, but hopefully everything is effective.

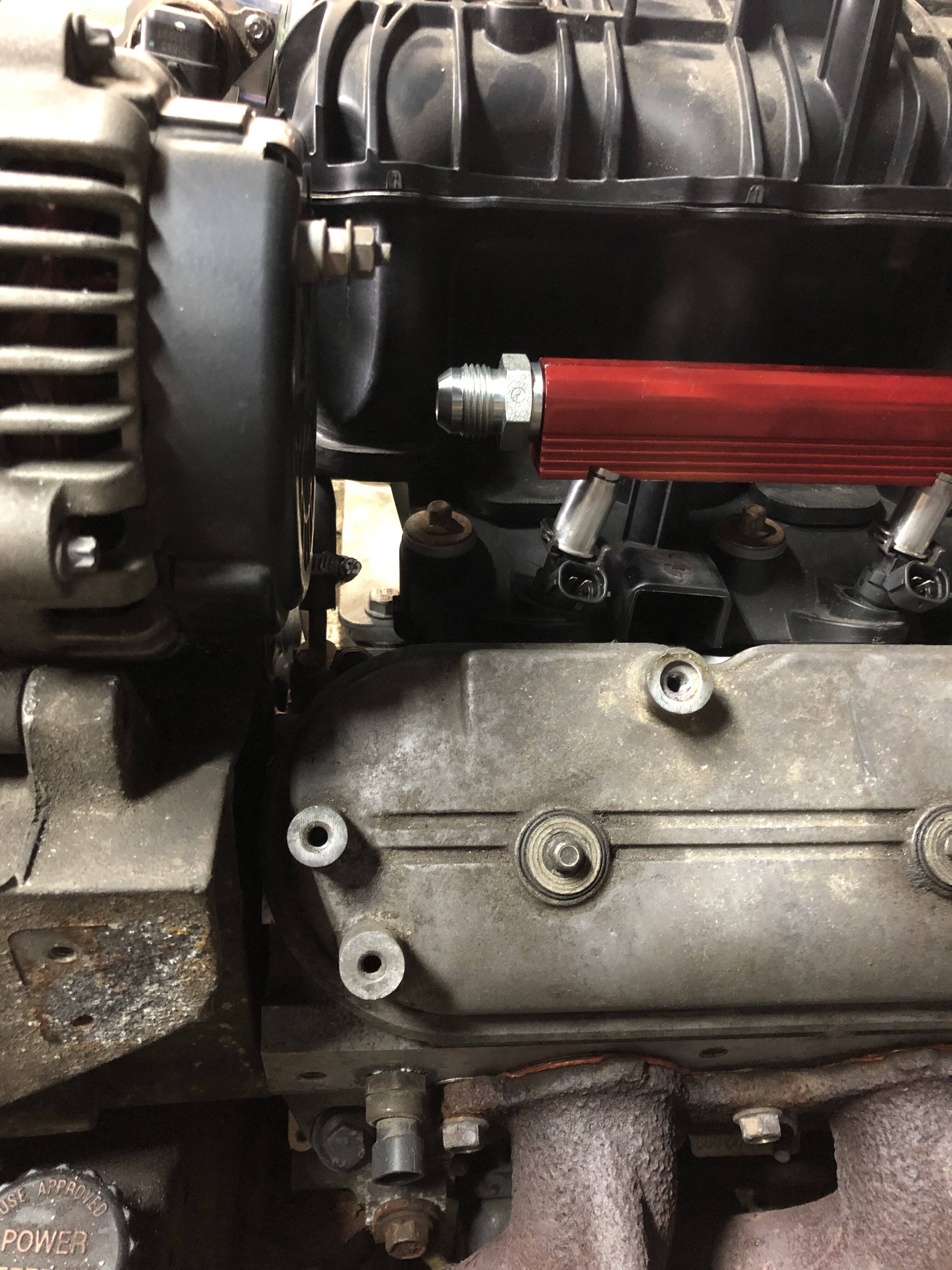

- ARB installed;

- removed the ethanol content sensor from the return line above the rear axle. Reason being that it would give erroneous readings due to air in the return line (I believe). Of course his only happens at 80+psi of fuel pressure and at wide open go. The Motion Race Works piece was expensive for me - over $100 lol;

- clearanced both the body, that was contacting the driveshaft, and the 8.8 truss bar that was hitting the upper a-arms. Both of these things only occurred when the left front comes off the ground, but I'm sure both have been slowing me down;

- re-located both fuel pumps to a lower position with the primary pump at the level of the tank sump. The reason for this is that the pumps suck air when there is still 3 or so gallons in the tank and it gets really noisy. Discovered this during Drag Week because we ran low on fuel a couple of times, but usually I always have 1/2 tank plus because I never let it get low when driving locally. It never caused much of an issue with normal driving because Mr. Holley would compensate easily, but I figured there wasn't a good reason not to fix it.

I spent the better part of the weekend working on it and I chuckle over my progress. Most everyone here post pics of really nice work and mine are.........ummm........much more function than form lol. All I need is a flux core welder to be in a certain someone's category 😉 :0 🙂

It's gonna haul butt or it will be the end of me hehe. More updates and photos comin soon.

Progress though. Nothing pretty, but hopefully everything is effective.

- ARB installed;

- removed the ethanol content sensor from the return line above the rear axle. Reason being that it would give erroneous readings due to air in the return line (I believe). Of course his only happens at 80+psi of fuel pressure and at wide open go. The Motion Race Works piece was expensive for me - over $100 lol;

- clearanced both the body, that was contacting the driveshaft, and the 8.8 truss bar that was hitting the upper a-arms. Both of these things only occurred when the left front comes off the ground, but I'm sure both have been slowing me down;

- re-located both fuel pumps to a lower position with the primary pump at the level of the tank sump. The reason for this is that the pumps suck air when there is still 3 or so gallons in the tank and it gets really noisy. Discovered this during Drag Week because we ran low on fuel a couple of times, but usually I always have 1/2 tank plus because I never let it get low when driving locally. It never caused much of an issue with normal driving because Mr. Holley would compensate easily, but I figured there wasn't a good reason not to fix it.

I spent the better part of the weekend working on it and I chuckle over my progress. Most everyone here post pics of really nice work and mine are.........ummm........much more function than form lol. All I need is a flux core welder to be in a certain someone's category 😉 :0 🙂

It's gonna haul butt or it will be the end of me hehe. More updates and photos comin soon.