More pics tomorrow - I actually spent some money on something (like wth 🤦♂️)

On the 'mildly' Cheap SS Monte Carlo chasing a 9.0___

- Thread starter 64nailhead

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Saw your at Byron, very impressive!!!

Geesh, you should’ve stopped in to visit. Jake and ole Bob were there as well.

Is pump 3 gonna be on a Hobbs switch or something?

All the pumps are controlled by the Holley. 2nd pump turns on at 10psi and the 3rd will be turned on at 18-20psi. I plan to be at the track tomorrow to test it out. I might have to adjust the 3rd pump trigger boost level. I’m watching for the pump to over run the return line by increasing pressure above 43+Boost level. So ideally the 3rd pump will turn on at 63 psi of fuel pressure (which will be 20psi of boost.)

Does it use check valves to prevent air pockets when #2 and #3 kick on? Or is that even a concern?

The AEM 400's come with a -08 outlet fitting that is also a check valve. So all three pumps have a check valve in them.Does it use check valves to prevent air pockets when #2 and #3 kick on? Or is that even a concern?

So I dropped 200 beans on this.

I had 3 relays in the trunk plus the solid state master disconnect and I figured adding another relay would add to the wiring disaster back there. It did make wiring the 3 pumps much easier. It’s somewhat overkill with 4 35 amp circuits for my pumps that use less than 20 each, but, ya know, sometimes you have to do what you have to do 😉

I had to add a wire into the Holley I/O box. Now I only have 2 outputs and 3 inputs left out of 8 each.

I know everyone isn’t using a Holley, but those of you that are, this I/O box extender is stupid simple to wire and get connected to the main ECU. It came with color coded and pinned wires. Installing a new wire into the connector takes minutes. And setting the software to use it took about 5 minutes.

I had 3 relays in the trunk plus the solid state master disconnect and I figured adding another relay would add to the wiring disaster back there. It did make wiring the 3 pumps much easier. It’s somewhat overkill with 4 35 amp circuits for my pumps that use less than 20 each, but, ya know, sometimes you have to do what you have to do 😉

I had to add a wire into the Holley I/O box. Now I only have 2 outputs and 3 inputs left out of 8 each.

I know everyone isn’t using a Holley, but those of you that are, this I/O box extender is stupid simple to wire and get connected to the main ECU. It came with color coded and pinned wires. Installing a new wire into the connector takes minutes. And setting the software to use it took about 5 minutes.

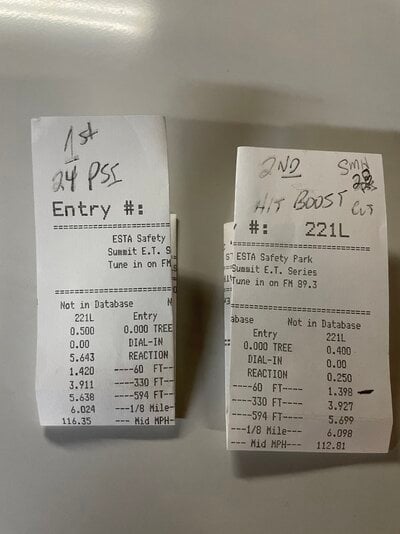

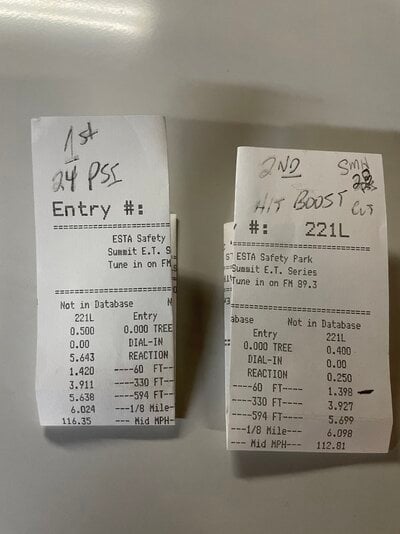

Made it to the track Sunday. They only ran 1/8 due to a wet shut down area - so that sucked somewhat.

The 3rd fuel pump works. I had a couple of minor issues with the settings after the 2nd run. I made a couple of adjustments to the activation of it and I made them in the wrong direction. When I did that, it never ran out of fuel to the point that the injectors weren't big enough, but he injectors had to compensate for my change. I also learned something about the Holley I/O box.

Regarding the I/O box that I recently praised, and still do, there is one thing about it that is different than the main ECU. Whenever a change is made to any of the settings or tables for the I/O a power down cycle HAS to be performed for the changes to take effect. The settings in the I/O box are are sent to the I/O box from the main ECU EVERYTIME the power is cycled. This unlike the main ECU which can have changes made on the fly. This is indicated in the instructions in a sentence that I had forgotten about. But live and learn.

Regarding the runs, the 1st was a low boost (24psi) to make sure the 3rd pump worked - it did. The second run was my best, except I forgot to turn off the boost safety from the 1st run. So during the second run when it hit 29psi I hit boost cut and it went to - degrees of timing and felt like the transmission slipped. It was late enough in the run that I just lifted and still ran a 6.098. But, the surprising win to me was my first sub 1.4 60'. Albeit barely less than 1.4, but I did not think that I would be able to get into a 1.3____anything with this low budget suspension setup and I WAS WRONG. If I hadn't hit the boost cut I'm quite sure I could've ran a 5.8 with that 60'.

From here it went down hill due to my I/O box programming somewhat, but more to the track prep was gone after 20 or so cars ran with street tires. Those of you that know about this, street tires destroy the track surface and turn it into virtually a no prep track. The last run I turned it it up, I launched at 12 psi and spun like hell - I lifted 3 times for traction and went almost 34psi of boost. When I got back to pits I was planning to make another run, but after the car sat for a couple of minutes and I restarted it, there was an abnormal noise after it heat soaked. I couldn't determine if it was an injector or bearing, bent rod, or what. I pulled both valve covers and ran it on four cylinders watching for rocker travel -all looked well. After I unplugged the driver side bank injectors the noise went away and ever returned. So I loaded up and went home. After getting home I never heard the noise again.

I've pulled the plugs and ran a compression test - previously I've had two cylinders that have been 10% lower than the other 6 - this hasn't bothered me much but has been noted. Well now, those two are 16-18% weaker than the best two and 4 others are at 10% from where they were. What does that mean Well something is going on and it's not good. I'm going to send the injectors out and re-test on the local on ramps before salt starts getting laid down. But no matter what, I'm going to pull the motor and tear it down to check crank and cam bearings, measure the bores and pistons for wear.

Some additional info about this motor, I'm at 50+ passes at 24-34psi of boost, I re-used all the bearings and never looked at the cam bearings on a 150k+ mile motor. Depending on what I find I might put in a piston and rod combination or not. ATM I'm not sure until I've determined the exact cause of the noise. I have to have it ready for Sick Week in February.

Overall, I'm farther ahead than I thought I could be. From the Sunday runs, I can consistently run low 1.4 60' and run sub 9.50 (6.0 1/8ths) consistently. This was not achievable until wingnutks help me dial in the rear the shocks and I can't say 'thank you' enough to him. I believe, optimistically on a good track with launching over 10psi that I can see an 8 with this thing with 32-34psi of boost. My goal for Sick Week is to average sub 9.3 and I believe I can do it targeting 30 psi. I'm going to keep grinding at it.

The 3rd fuel pump works. I had a couple of minor issues with the settings after the 2nd run. I made a couple of adjustments to the activation of it and I made them in the wrong direction. When I did that, it never ran out of fuel to the point that the injectors weren't big enough, but he injectors had to compensate for my change. I also learned something about the Holley I/O box.

Regarding the I/O box that I recently praised, and still do, there is one thing about it that is different than the main ECU. Whenever a change is made to any of the settings or tables for the I/O a power down cycle HAS to be performed for the changes to take effect. The settings in the I/O box are are sent to the I/O box from the main ECU EVERYTIME the power is cycled. This unlike the main ECU which can have changes made on the fly. This is indicated in the instructions in a sentence that I had forgotten about. But live and learn.

Regarding the runs, the 1st was a low boost (24psi) to make sure the 3rd pump worked - it did. The second run was my best, except I forgot to turn off the boost safety from the 1st run. So during the second run when it hit 29psi I hit boost cut and it went to - degrees of timing and felt like the transmission slipped. It was late enough in the run that I just lifted and still ran a 6.098. But, the surprising win to me was my first sub 1.4 60'. Albeit barely less than 1.4, but I did not think that I would be able to get into a 1.3____anything with this low budget suspension setup and I WAS WRONG. If I hadn't hit the boost cut I'm quite sure I could've ran a 5.8 with that 60'.

From here it went down hill due to my I/O box programming somewhat, but more to the track prep was gone after 20 or so cars ran with street tires. Those of you that know about this, street tires destroy the track surface and turn it into virtually a no prep track. The last run I turned it it up, I launched at 12 psi and spun like hell - I lifted 3 times for traction and went almost 34psi of boost. When I got back to pits I was planning to make another run, but after the car sat for a couple of minutes and I restarted it, there was an abnormal noise after it heat soaked. I couldn't determine if it was an injector or bearing, bent rod, or what. I pulled both valve covers and ran it on four cylinders watching for rocker travel -all looked well. After I unplugged the driver side bank injectors the noise went away and ever returned. So I loaded up and went home. After getting home I never heard the noise again.

I've pulled the plugs and ran a compression test - previously I've had two cylinders that have been 10% lower than the other 6 - this hasn't bothered me much but has been noted. Well now, those two are 16-18% weaker than the best two and 4 others are at 10% from where they were. What does that mean Well something is going on and it's not good. I'm going to send the injectors out and re-test on the local on ramps before salt starts getting laid down. But no matter what, I'm going to pull the motor and tear it down to check crank and cam bearings, measure the bores and pistons for wear.

Some additional info about this motor, I'm at 50+ passes at 24-34psi of boost, I re-used all the bearings and never looked at the cam bearings on a 150k+ mile motor. Depending on what I find I might put in a piston and rod combination or not. ATM I'm not sure until I've determined the exact cause of the noise. I have to have it ready for Sick Week in February.

Overall, I'm farther ahead than I thought I could be. From the Sunday runs, I can consistently run low 1.4 60' and run sub 9.50 (6.0 1/8ths) consistently. This was not achievable until wingnutks help me dial in the rear the shocks and I can't say 'thank you' enough to him. I believe, optimistically on a good track with launching over 10psi that I can see an 8 with this thing with 32-34psi of boost. My goal for Sick Week is to average sub 9.3 and I believe I can do it targeting 30 psi. I'm going to keep grinding at it.

Last edited:

Sooooooooooooo..... it might not be running on all 8 cylinders?Made it to the track Sunday. They only ran 1/8 due to a wet shut down area - so that sucked somewhat.

View attachment 208783

View attachment 208784

The 3rd fuel pump works. I had a couple of minor issues with the settings after the 2nd run. I made a couple of adjustments to the activation of it and I made them in the wrong direction. When I did that, it never ran out of fuel to the point that the injectors weren't big enough, but he injectors had to compensate for my change. I also learned something about the Holley I/O box.

Regarding the I/O box that I recently praised, and still do, there is one thing about it that is different than the main ECU. Whenever a change is made to any of the settings or tables for the I/O a power down cycle HAS to be performed for the changes to take effect. The settings in the I/O box are are sent to the I/O box from the main ECU EVERYTIME the power is cycled. This unlike the main ECU which can have changes made on the fly. This is indicated in the instructions in a sentence that I had forgotten about. But live and learn.

Regarding the runs, the 1st was a low boost (24psi) to make sure the 3rd pump worked - it did. The second run was my best, except I forgot to turn off the boost safety from the 1st run. So during the second run when it hit 29psi I hit boost cut and it went to - degrees of timing and felt like the transmission slipped. It was late enough in the run that I just lifted and still ran a 6.098. But, the surprising win to me was my first sub 1.4 60'. Albeit barely less than 1.4, but I did not think that I would be able to get into a 1.3____anything with this low budget suspension setup and I WAS WRONG. If I hadn't hit the boost cut I'm quite sure I could've ran a 5.8 with that 60'.

From here it went down hill due to my I/O box programming somewhat, but more to the track prep was gone after 20 or so cars ran with street tires. Those of you that know about this, street tires destroy the track surface and turn it into virtually a no prep track. The last run I turned it it up, I launched at 12 psi and spun like hell - I lifted 3 times for traction and went almost 34psi of boost. When I got back to pits I was planning to make another run, but after the car sat for a couple of minutes and I restarted it, there was an abnormal noise after it heat soaked. I couldn't determine if it was an injector or bearing, bent rod, or what. I pulled both valve covers and ran it on four cylinders watching for rocker travel -all looked well. After I unplugged the driver side bank injectors the noise went away and ever returned. So I loaded up and went home. After getting home I never heard the noise again.

I've pulled the plugs and ran a compression test - previously I've had two cylinders that have been 10% lower than the other 6 - this hasn't bothered me much but has been noted. Well now, those two are 16-18% weaker than the best two and 4 others are at 10% from where they were. What does that mean Well something is going on and it's not good. I'm going to send the injectors out and re-test on the local on ramps before salt starts getting laid down. But no matter what, I'm going to pull the motor and tear it down to check crank and cam bearings, measure the bores and pistons for wear.

Some additional info about this motor, I'm at 50+ passes at 24-34psi of boost, I re-used all the bearings and never looked at the cam bearings on a 150k+ mile motor. Depending on what I find I might put in a piston and rod combination or not. ATM I'm not sure until I've determined the exact cause of the noise. I have to have it ready for Sick Week in February.

Overall, I'm farther ahead than I thought I could be. From the Sunday runs, I can consistently run low 1.4 60' and run sub 9.50 (6.0 1/8ths) consistently. This was not achievable until wingnutks help me dial in the rear the shocks and I can't say 'thank you' enough to him. I believe, optimistically on a good track with launching over 10psi that I can see an 8 with this thing with 32-34psi of boost. My goal for Sick Week is to average sub 9.3 and I believe I can do it targeting 30 psi. I'm going to keep grinding at it.

Similar threads

- Replies

- 1

- Views

- 220

- Replies

- 0

- Views

- 580

- Replies

- 0

- Views

- 40

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.