If anyone thinks that I look like a spaz in the car, then please realize...............

I am 😉

I am 😉

If anyone thinks that I look like a spaz in the car, then please realize...............

I am 😉

What was the best ET? Am I missing something?Summit Midwest Drags 2023 is in the books. A new PB every day - so I have no complaints.

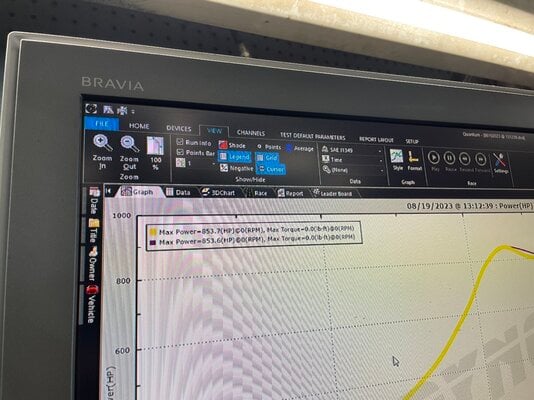

This is the best I could do throughout the week. Saved it for the last day haha (not really - I tried like hell all week). The weather sucked for going fast - humidity through the roof and Virginia weather 90 degrees or so. I've looked over the logs too many times to recount. I'm sure that cooler weather, or some night racing would help me by a .1. But I'm still missing some ET for the amount of boost and fuel consumption that I'm seeing - I SHOULD BE FASTER AT 33PSI!

I'm sill in disbelief that this thing has more left in it. The attached videos were taken by the young lady that gave me the car (how strange is that??) She is a professional photographer for a couple of teams that run the PDRA series. She setup an in car camera as well that she still has to send me the vids from.

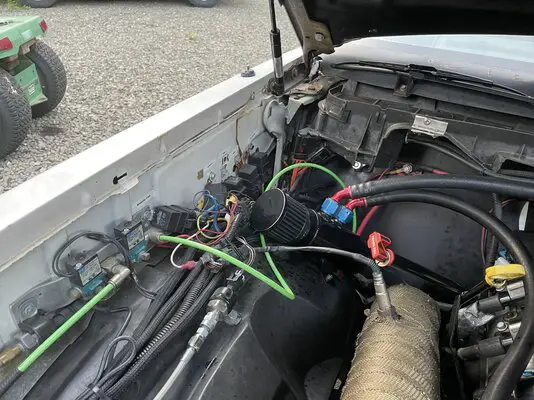

The problems encountered - a rear caliper got a little too hot and locked up during the 6+ hour drive on day one; I blew the FPR boost reference line off on day 3 and made it to 41 psi of boost before the boost cut shut off the motor - thank you Bosch 210's and Holley closed loop correction - never leaned out and saved the motor.

View attachment 224617

View attachment 224618

View attachment 224619

View attachment 224620

View attachment 224622

9.211What was the best ET? Am I missing something?

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.