Oops, I think I goofed!

- Thread starter 86judge

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Buy an intake. And for future reference, the only port matching worth doing is to correct the issue you created. If the head is bigger than the intake then leave it alone.

If the only time port work needs to b done is after a mistake then it would never be done to begin with.Buy an intake. And for future reference, the only port matching worth doing is to correct the issue you created. If the head is bigger than the intake then leave it alone.

I didn’t say porting. If you are going to port the intake from the carb base to the head, then go for it. Gasket matching on its own with a smaller intake than the head runner does nothing. It’s better to have the intake port smaller. It keeps velocity up in the port and creates a step to keep gases from returning up the intake path to the carb in the event of reversion.

No harm no foul,matching is a lot of time consumed and i'd hate to see you give up half way through because you're tired of it or don't have the time etc etc and buying more parts equals more money.you didn't wreck anything in the process they're still good use them.

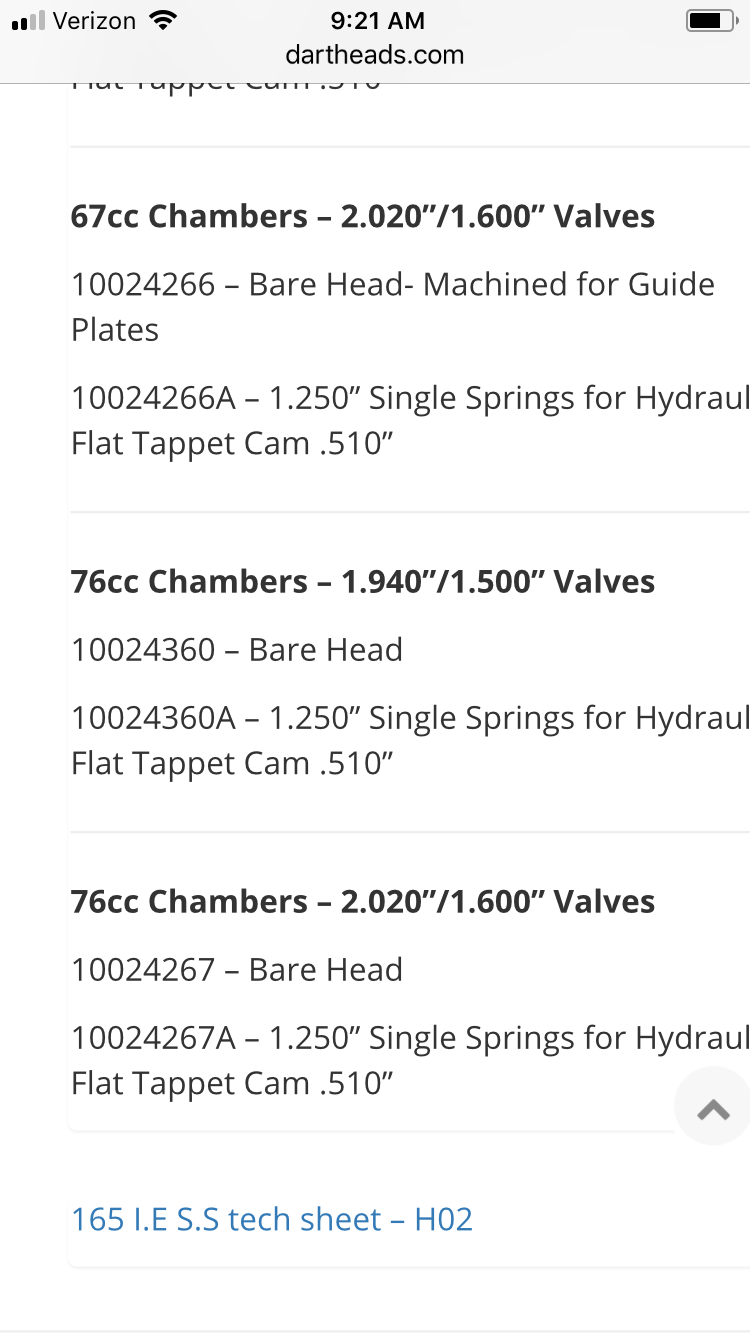

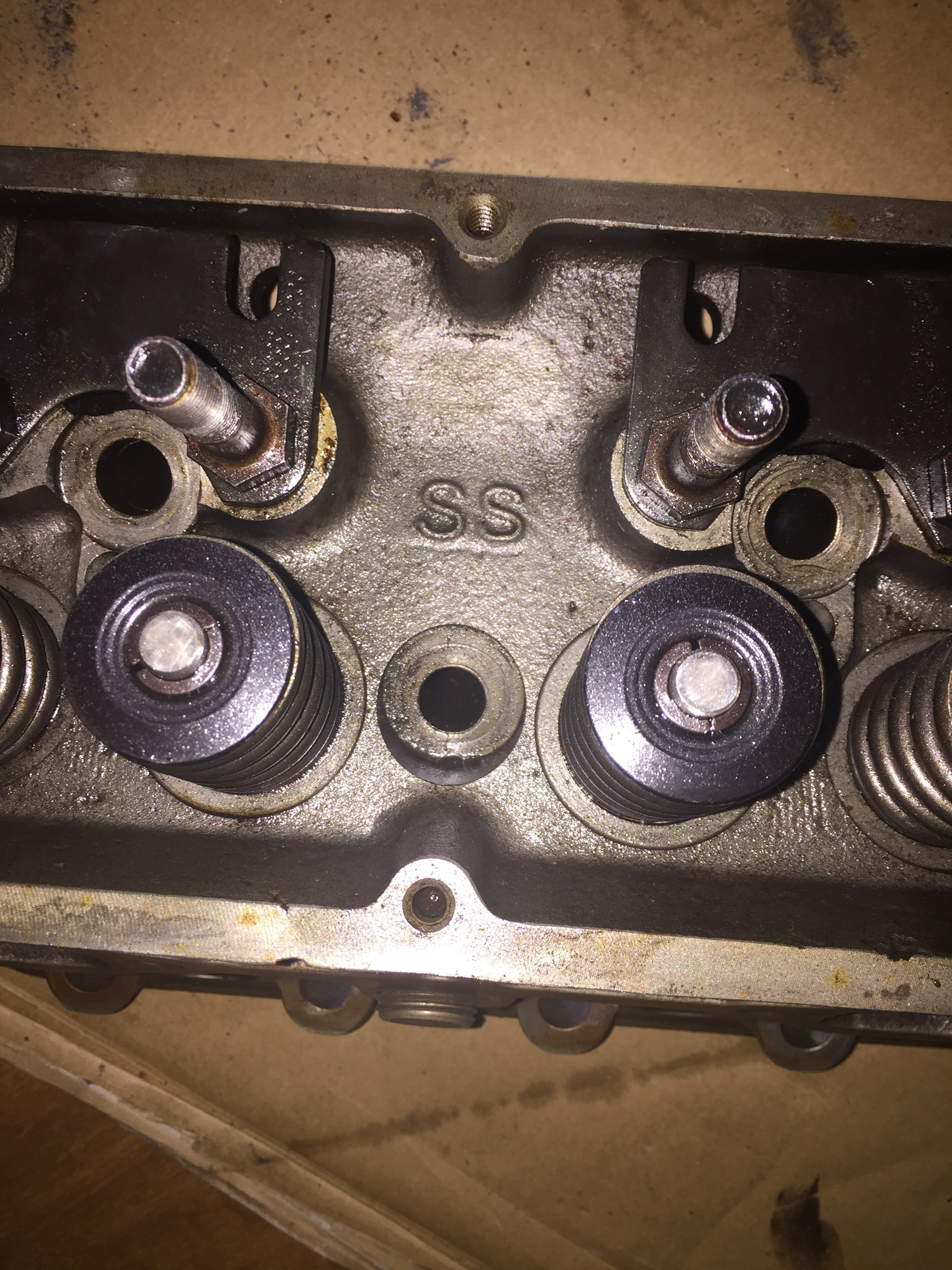

I definitely don’t mind the work. I just didn’t want to junk a set of heads. The reason why I wrote the post was to find some direction. I appreciate all response. I kinda knew bigger wasn’t better (volume vs velocity) I just shld of checked both sides before I started. I figured a little bigger wasn’t going to kill it because it has a decent amount of cubic inches. 406 sbc. The heads are dart heads but there the big runner heads.No harm no foul,matching is a lot of time consumed and i'd hate to see you give up half way through because you're tired of it or don't have the time etc etc and buying more parts equals more money.you didn't wreck anything in the process they're still good use them.

So much depends on what you want this engine to do and cam you plan on using. You are going to spend endless hours on these heads, you are beyond port matching. A 1204 gasket is what these heads call for. If your building a torque engine your heads will work (bottom- mid range)anything more they won't breath especially with a 406. I would like to here what your goals are.

My goal is just fun in the street. It’s a lot of parts piced together because of a very limited budget. The motor is a 406, with about 10.5 to 1, roller cam 236/242 @50 110 lob sep 106 icl 520 540 lift, it’s going in an 86 cutlass muncie m20 with 355 posiSo much depends on what you want this engine to do and cam you plan on using. You are going to spend endless hours on these heads, you are beyond port matching. A 1204 gasket is what these heads call for. If your building a torque engine your heads will work (bottom- mid range)anything more they won't breath especially with a 406. I would like to here what your goals are.

- Status

- Not open for further replies.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.