Oops, I think I goofed!

- Thread starter 86judge

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

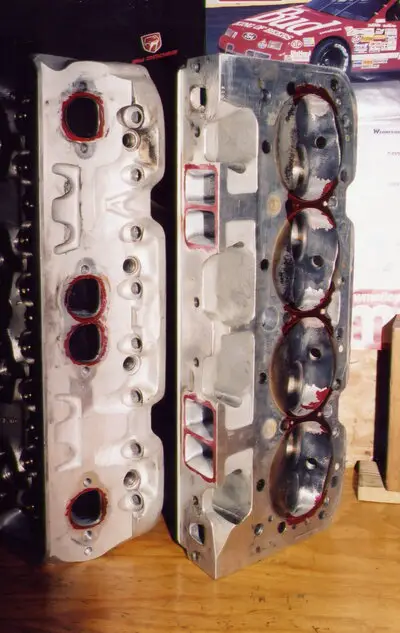

Yeah, but there what I have and that’s what’s going on it.165 cc heads, those are pretty small for a 406 even in a street application.

Yeah, but there what I have and that’s what’s going on it.

In my opinion you have quite a miss match with your cam & heads. If that's the way you look at it just bolt the intake on too.

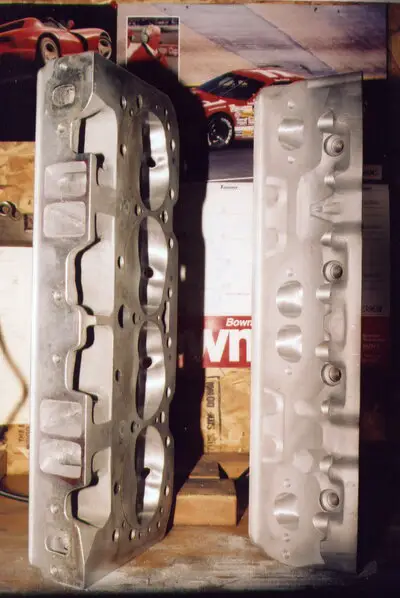

Greetings Judge & all; Flash back guys, we all started somewhere with the parts we could afford or find at the time. And the only guy that doesn't screw up is the one that doesn't try to do something (couch potato). Us Afflicted are always trying to fine 3 HP for $5 bucks. And we want it today! I ported my first heads back in 1962-63 (?) & after the war took auto engines (tech school). One of the few times I got "A's". I got my dream job in a Very fine engine shop. Anyway Please buy a couple of books on head porting, today. Read them next week, the following week start grinding. I understand their iron, so just except that ya got a months worth of your spare time used up! Mock up & Temples are a Must. Start with putting the heads on the block (dowel pins & two or three bolts), next scribe intake dividers so ya can see where they are with intake "on". Next set intake gaskets on head faces, now "do ya want the gasket to set on the block valley-intake surface front & rear or are ya going need to raise it"? If ya need to raise the gasket above the block surface, ya "Gotta Mark" it. And your marks have to be visible with intake on! So with intake off, gaskets on, use washers & short intake bolts finger tight. Use cold chisel mark front & back edges of the heads & gasket in the same hammer swing. At this point you have a little "V" mark in the head & gasket. Now put the intake on with gaskets (four bolts finger tight) & transfer the marks to the intake manifold. Now your gaskets are your templets. Paint your heads & intake mating surfaces with machinist dye (OK magic marker) & scribe the new openings using gaskets healed into position with washers, bolts & nuts where required (intake). Then with new knowledge (porting books ya bought) & a new porting kit (Eastwood?), ya this will cost about $150 -$200 total & a good month. But the results will be well worth it. As fellow member mentioned your heads may be a Bit small for the cam - inch combo you're planing. I've built three 406 incher's, lots of bang for the buck. Get grindin', Ole" Bob.

Attachments

Greetings TC & all; I see that ya just posted this picture.

From my experience you may have some poorly machined adjoining surfaces? Or the gasket was compressed to much in that area setting the intake on & or during the first tightening sequence? Just my $.02 cents as I've had very good results with the FelPro gaskets. Try setting the intake on with out a gaskets, put a couple flashlights in the valley & use a mirror. Look around & see if the gaps are constance? Good Luck, Ole' Bob.Those gaskets are not very good they do this.

Thanks for the info. That sounds like a plan. I sold the 383 out of the car I had pretty good money in. (Life happens) this motor is an accumulation of parts that I have collected thru work, helping people that didn’t have money to spend so I’m just making due with what I have this round. Again thanks for taking the time to respondGreetings Judge & all; Flash back guys, we all started somewhere with the parts we could afford or find at the time. And the only guy that doesn't screw up is the one that doesn't try to do something (couch potato). Us Afflicted are always trying to fine 3 HP for $5 bucks. And we want it today! I ported my first heads back in 1962-63 (?) & after the war took auto engines (tech school). One of the few times I got "A's". I got my dream job in a Very fine engine shop. Anyway Please buy a couple of books on head porting, today. Read them next week, the following week start grinding. I understand their iron, so just except that ya got a months worth of your spare time used up! Mock up & Temples are a Must. Start with putting the heads on the block (dowel pins & two or three bolts), next scribe intake dividers so ya can see where they are with intake "on". Next set intake gaskets on head faces, now "do ya want the gasket to set on the block valley-intake surface front & rear or are ya going need to raise it"? If ya need to raise the gasket above the block surface, ya "Gotta Mark" it. And your marks have to be visible with intake on! So with intake off, gaskets on, use washers & short intake bolts finger tight. Use cold chisel mark front & back edges of the heads & gasket in the same hammer swing. At this point you have a little "V" mark in the head & gasket. Now put the intake on with gaskets (four bolts finger tight) & transfer the marks to the intake manifold. Now your gaskets are your templets. Paint your heads & intake mating surfaces with machinist dye (OK magic marker) & scribe the new openings using gaskets healed into position with washers, bolts & nuts where required (intake). Then with new knowledge (porting books ya bought) & a new porting kit (Eastwood?), ya this will cost about $150 -$200 total & a good month. But the results will be well worth it. As fellow member mentioned your heads may be a Bit small for the cam - inch combo you're planing. I've built three 406 incher's, lots of bang for the buck. Get grindin', Ole" Bob.

Bob

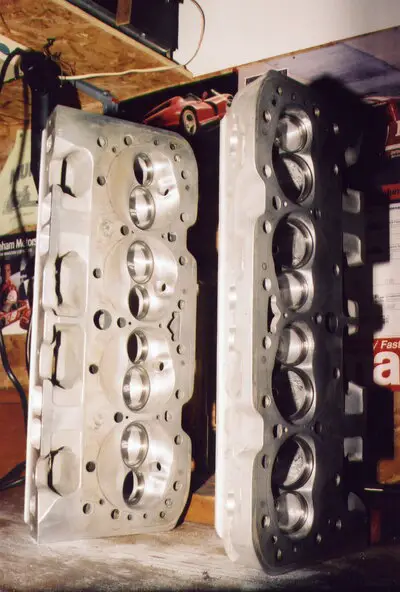

Back in the day I couldn't agree with you more BUT there isn't any sense now days in putting that kind of money time and effort in a stock replacement head when there are far superior designed heads to the specs you want. I've seen quite a few so called port jobs that are disasters. I have a set of 340292 heads with extensive work, 2.05 SS valves bronze guides and opened up to 208 runners that no one would give half of what's in them.

Back in the day I couldn't agree with you more BUT there isn't any sense now days in putting that kind of money time and effort in a stock replacement head when there are far superior designed heads to the specs you want. I've seen quite a few so called port jobs that are disasters. I have a set of 340292 heads with extensive work, 2.05 SS valves bronze guides and opened up to 208 runners that no one would give half of what's in them.

- Status

- Not open for further replies.

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.