HUGE RELIEF !! The broken bolt was NOT a broken bolt. It ended up being debris clogging up the bolt hole. I had my copper tube & welder set up. But I also had (4) sizes of hardened left hand drill bits laid out, and decided to use my center punch to get my drill bit centered. I tapped the punch with my hammer, and the punch fell to the bottom of the hole. WTF... I cleaned the hole out with a pic, compressed air, a few drops of oil, and my thread chaser. (5) minutes later, starter installed, and bolts torqued. THANK GOODNESS! I knew I had not missed that before taking the block to the machine shop, and their block inspection sheet did not mention it. I assume it happened while cleaning the block. I had been stressing over this all week. Moving on...

PROJECT " LAID BACK 2 " - 1978 SALON 2 DOOR AEROBACK

- Thread starter JAMCAR223

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

I still have a cast iron reverse rotation Olds diesel water pump that I am probably never going to use. James, do you want it? Just pay shipping and I'll send it to ya. Let me go get it it and check it to make sure from sitting that it doesn't have any problems. And I'll get some pics. Anything I can do to help get this engine done and in the car!!I guess my reverse rotation water pump was one of the last cores on the planet. Everything is still moving at a snail's pace.

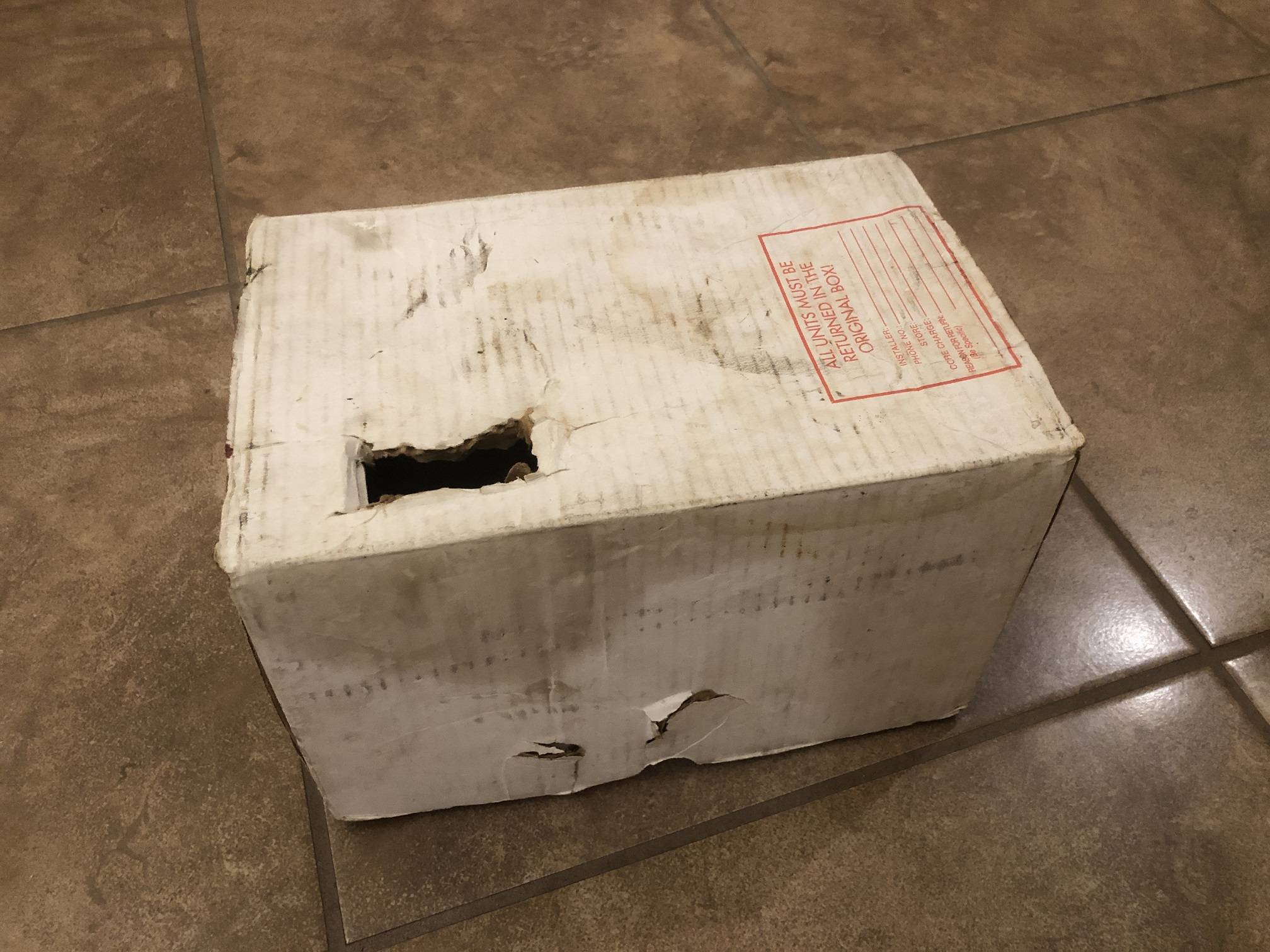

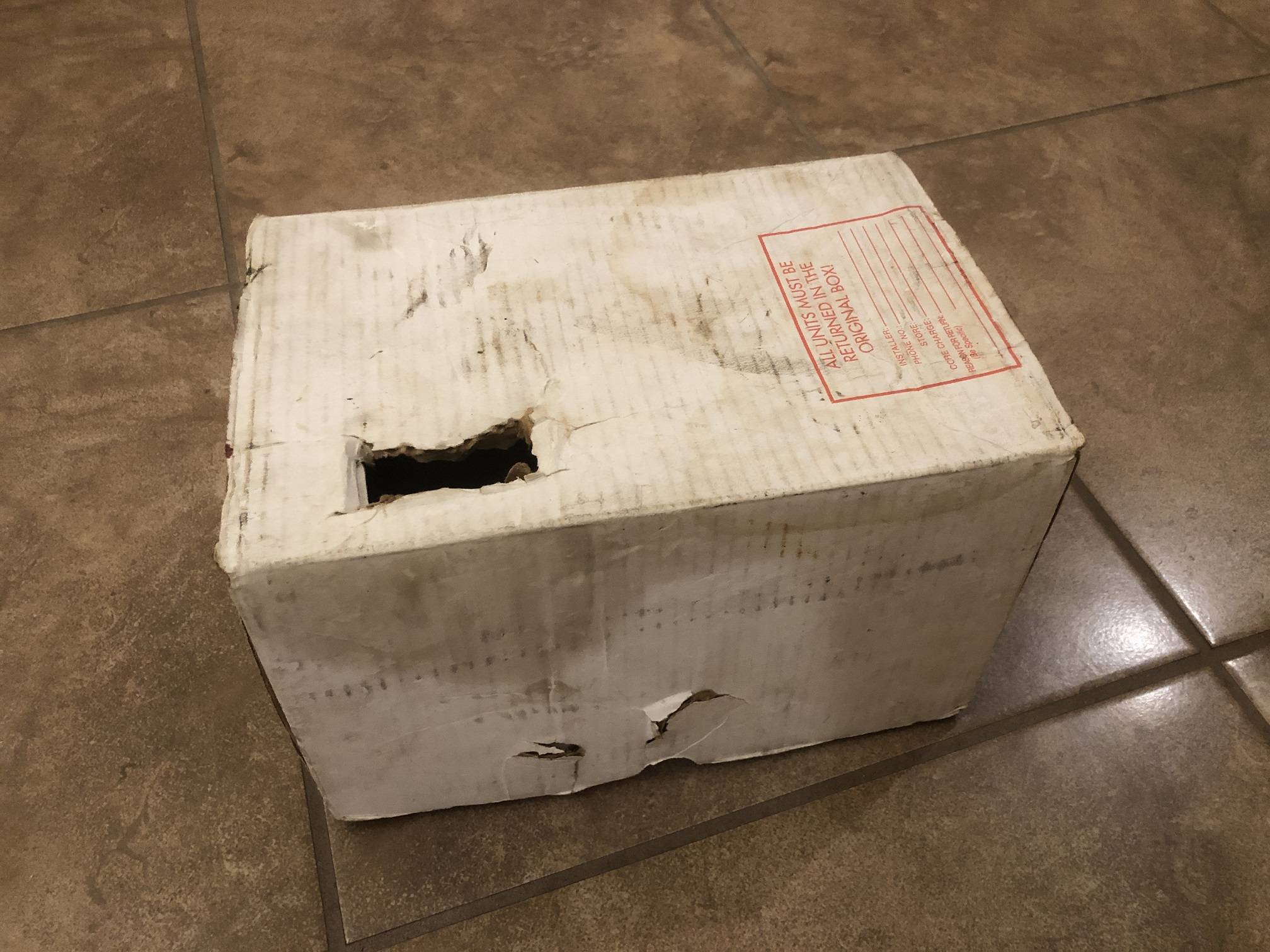

Here it is. It still seems to turn nicely.

A little cleanup and paint and it should be good to go.

A little cleanup and paint and it should be good to go.

Nice, a factory style closed impeller pump. I was not sure they existed for the V6 diesel pump.Here it is. It still seems to turn nicely.

View attachment 172724

View attachment 172721

View attachment 172720

View attachment 172722

View attachment 172723

A little cleanup and paint and it should be good to go.

Joe, that is very generous of you! Yes, I would love to have it. I'll be honest, I will send this casting to Flowkooler, and have them go through it, and install their upgraded aluminum impeller. Take it to your choice of shippers, and send it. I'll pay you back that same day. I'll text you my address. No need for you to look back through our previous transactions to find it. Big thanks to you!! 👍 👍Here it is. It still seems to turn nicely.

View attachment 172724

View attachment 172721

View attachment 172720

View attachment 172722

View attachment 172723

A little cleanup and paint and it should be good to go.

No problem James! I'll see if I can get it shipped on Monday. Gotta go through my pile of broken down Amazon boxes to see if I have something slightly bigger than the original box.

Shipped today via UPS! Can't wait to see this engine together.

Speechless at the generosity that several Forum Members have shown me. From going to look at parts for me, going to buy parts for me, shipping parts to me, and giving parts to me. You guys know who you are, and I give you all a very heartfelt thank you! I have said it several times before, and I will say it again... This is the best group of guys, on the best Forum EVER !

We just wanted your address so we know where to come and steal that Salon when you're done. 🙂

- Status

- Not open for further replies.

Similar threads

- Replies

- 25

- Views

- 922

- Replies

- 14

- Views

- 813

- Replies

- 10

- Views

- 487

GBodyForum is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to amazon.com. Amazon, the Amazon logo, AmazonSupply, and the AmazonSupply logo are trademarks of Amazon.com, Inc. or its affiliates.