So I have been a little lazy updating this build thread, but I have made some progress.

I got the Holley Hyperspark coil. I'm not sure where I'm going to mount this yet. If anybody has any pics of their coil installed. Post them up.

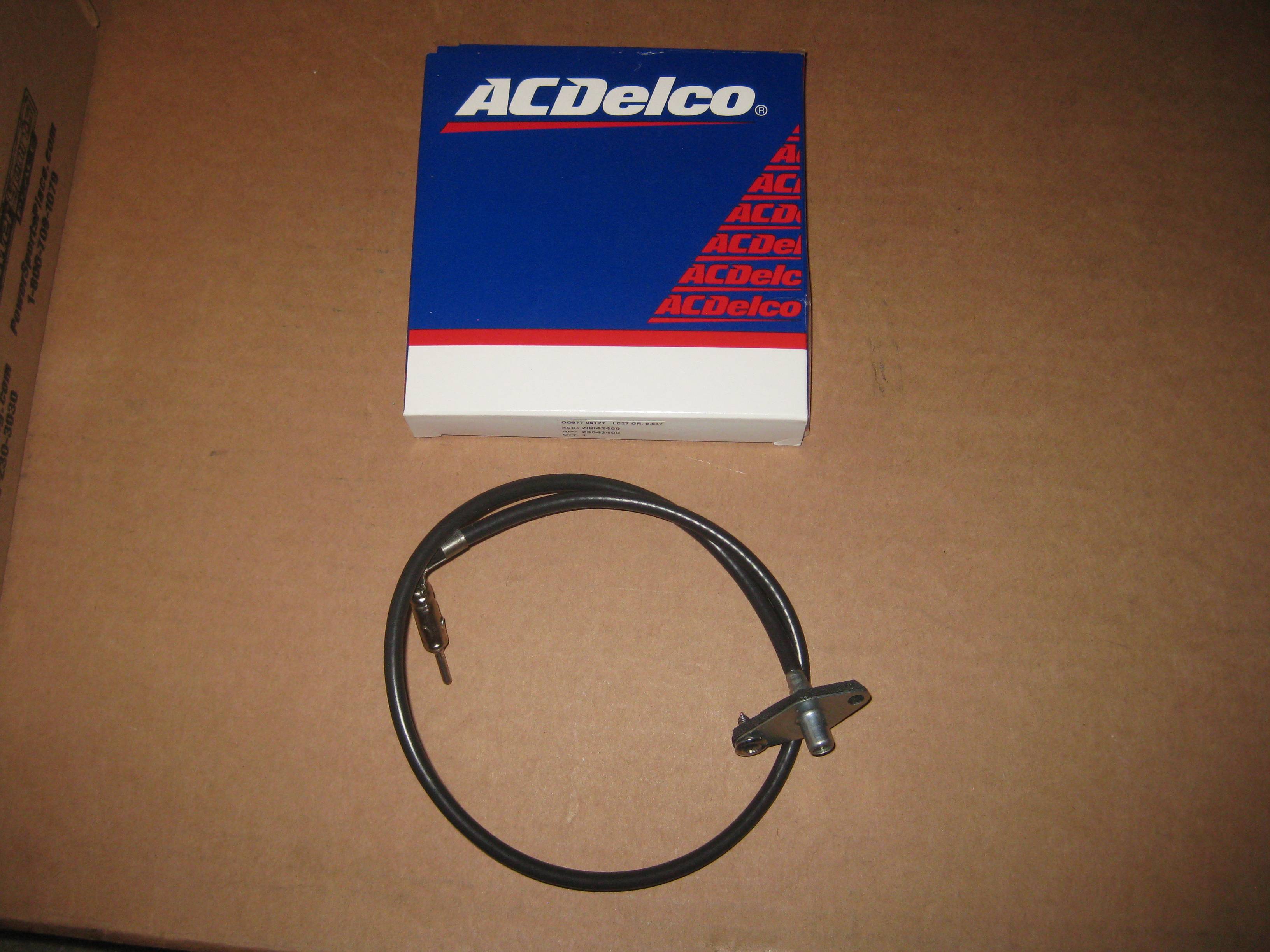

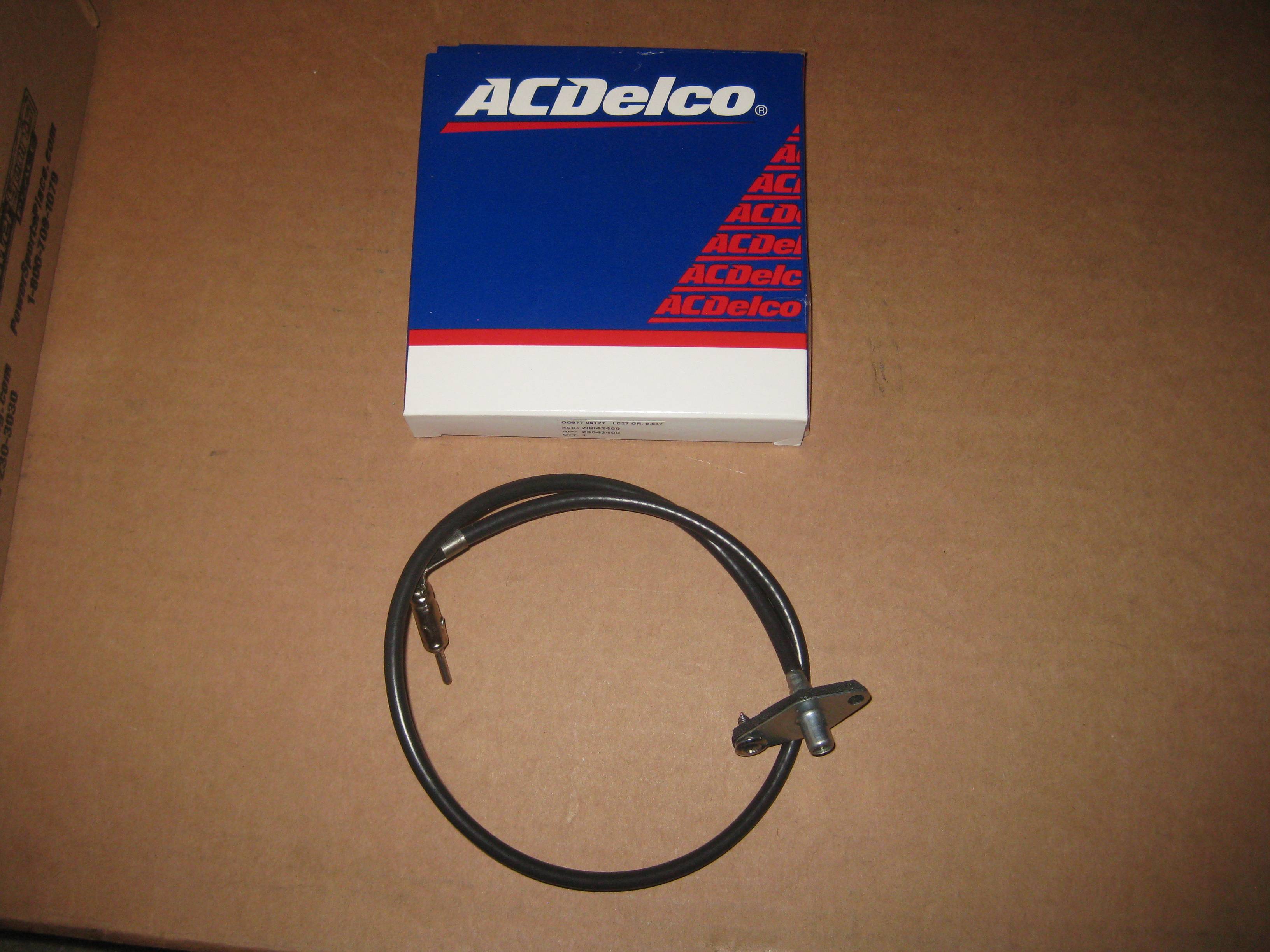

I got a new AC Delco windshield antenna lead from a Forum Member. I bet this item gets overlooked a lot. Not this time...

I also got a very nice set of used 40k mile original GM black door handles, and key cylinders w/ original GM keys from a friend that totaled his GN show car. I will be blacking out all the trim on this car, so I'm very happy to have these. This beats aftermarket junk all day long!

I got Joe's donated closed impellar H/D water pump cleaned and painted. It will make a great spare. Between Joe's water pump, and the Flowkooler, they should last the lifetime of this car (and me) 🤣 .

Cleaned on the wire wheel, and painted.

Cleaned on the wire wheel, and painted.

I got the Flowkooler water pump, I waited (10) weeks for. You can see their aluminum multi-vein, military grade 2 anodized impeller. I painted it to match the block & heads. Also got the Robert Shaw 180 high flow thermostat. It's supposed to be the best... 🤷♂️

I also got my Inline Tube aftermarket dip stick tube installed. This thing gave me a hard time. You can see the (2) ribs that need to go into the block to seal. They would not... My service manual says to install a 1/4-20 bolt into the tube, and drive the tube into the block, by hitting the bolt head with a hammer ( this protects the tube ). It would not! I had to use some emory cloth to sand the ribs down. (10) twirls around the tube and check. (10) more and check. again and again... Finally got it in nice and tight. These aftermarket parts...

I installed the rest of the valve train. After adjusting all the valves, I determined that custom length pushrods are NOT needed!! Jim Lapikas told me ( before he got silly ) that these longer Comp Cams push rods were a match for the longer length valves. Everything seems to be good here. ARP screw in studs - Comp Cams guide plates - Comp Cams roller tip rockers - Edelbrock valve springs.

I installed the Edelbrock Performer RPM intake manifold using ARP 12 point stainless bolts. Another mild headache here, but I prevailed. The ARP bolts are great, but the runner size/casting is larger than stock, so bolt head clearance is an issue on (2) bolts. On (1) of the bolts, I had to grind down my 3/8" 12 point box end wrench on the grinder to get the bolt tight ( no big deal - I used my Harbor Freight wrench 🤣 ). On the 2nd bolt, It required a lot more effort... I had to grind the ARP bolt head flange down with my bench grinder, shorten the bolt 3/16", grind the washer down, and grind the runner on my freshly coated intake. Luckily it's on the back side of the runner, and since the intake is silver, you can hardly even tell. Geezzz!

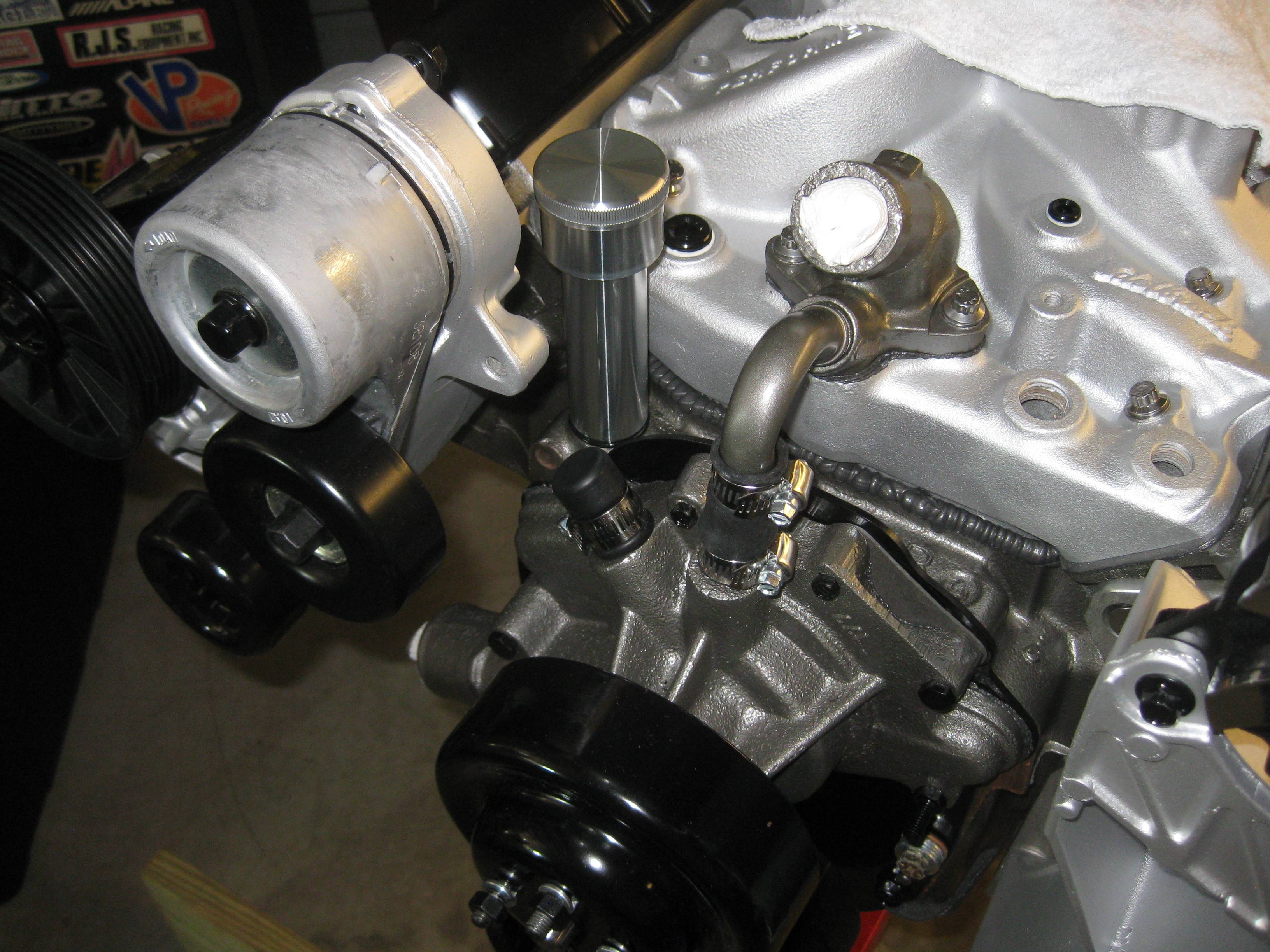

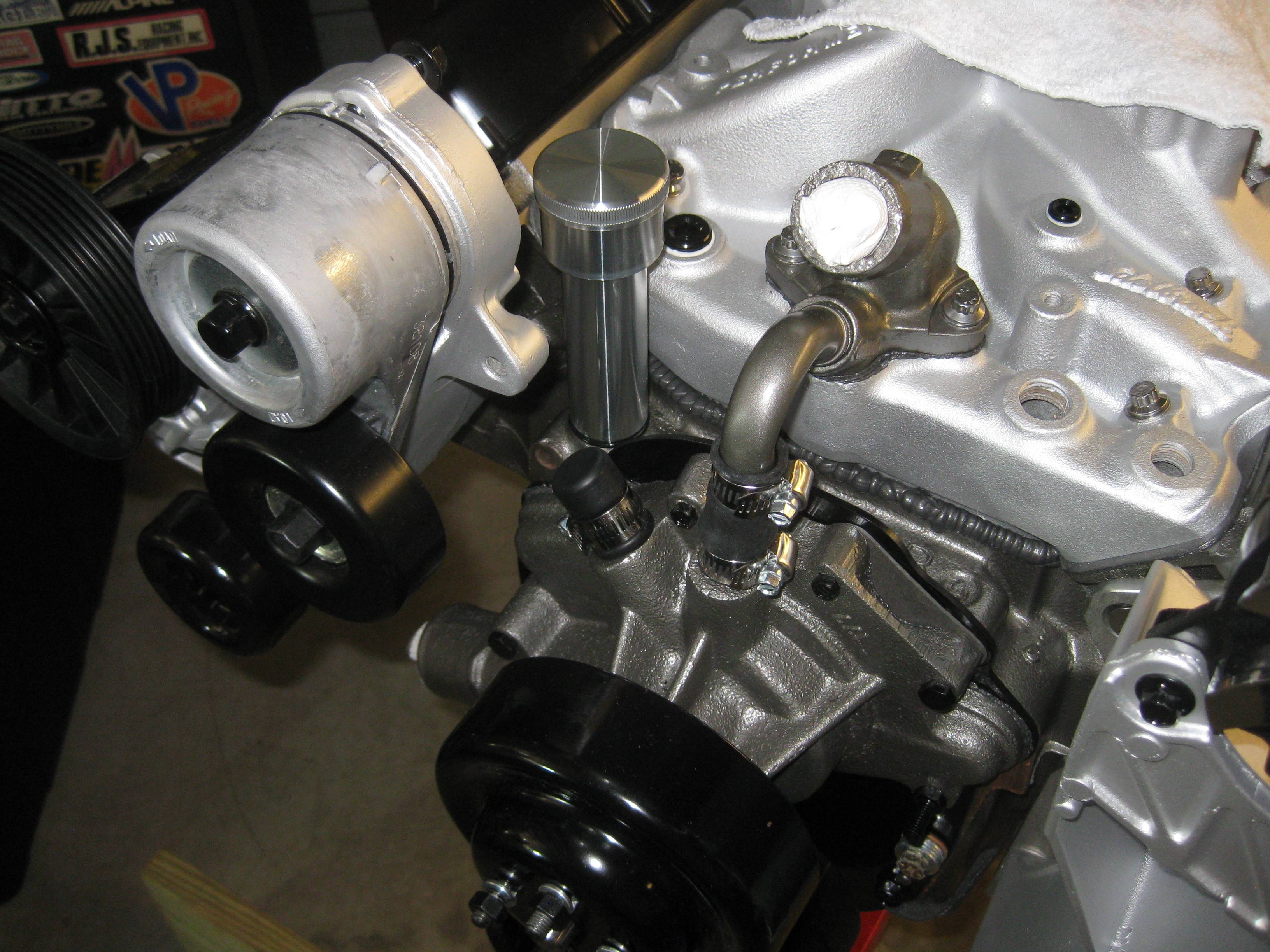

I installed the March billet oil filler tube. I used a few drops of oil on the tube, and a block of wood wrapped in a towel, and tapped it into the block using a dead blow hammer.

AC Delco temp sensor, Robert Shaw thermostat, thermostat housing are all installed onto the intake manifold.

So here is where I'm at...

On another note. I have gotten a flush mount bezel for the Holley 3.5" screen. I will flush mount this bezel into my center dash bezel. The overall size of the bezel's flange was too big, but I knew I could customize this to fit by trimming the flange around the bezel.

It's a 3D printed item, I found on Ebay.

It's a 3D printed item, I found on Ebay.

(10) mimutes on the bench grinder, and a quick block sand, and I'm pretty close... My bezel is warped, so I'm waiting on a replacement from Kevin to get here from Canada, to finish this out.

I have several items on order, but I will be waiting on Holley again... 6.86 Pro Dash, in-tank electric fuel pump, and Hyperspark ignition box. None of this was in stock. That's all for now. Questions. comments, and concerns... always welcome ✌️

I have several items on order, but I will be waiting on Holley again... 6.86 Pro Dash, in-tank electric fuel pump, and Hyperspark ignition box. None of this was in stock. That's all for now. Questions. comments, and concerns... always welcome ✌️

I got the Holley Hyperspark coil. I'm not sure where I'm going to mount this yet. If anybody has any pics of their coil installed. Post them up.

I got a new AC Delco windshield antenna lead from a Forum Member. I bet this item gets overlooked a lot. Not this time...

I also got a very nice set of used 40k mile original GM black door handles, and key cylinders w/ original GM keys from a friend that totaled his GN show car. I will be blacking out all the trim on this car, so I'm very happy to have these. This beats aftermarket junk all day long!

I got Joe's donated closed impellar H/D water pump cleaned and painted. It will make a great spare. Between Joe's water pump, and the Flowkooler, they should last the lifetime of this car (and me) 🤣 .

I got the Flowkooler water pump, I waited (10) weeks for. You can see their aluminum multi-vein, military grade 2 anodized impeller. I painted it to match the block & heads. Also got the Robert Shaw 180 high flow thermostat. It's supposed to be the best... 🤷♂️

I also got my Inline Tube aftermarket dip stick tube installed. This thing gave me a hard time. You can see the (2) ribs that need to go into the block to seal. They would not... My service manual says to install a 1/4-20 bolt into the tube, and drive the tube into the block, by hitting the bolt head with a hammer ( this protects the tube ). It would not! I had to use some emory cloth to sand the ribs down. (10) twirls around the tube and check. (10) more and check. again and again... Finally got it in nice and tight. These aftermarket parts...

I installed the rest of the valve train. After adjusting all the valves, I determined that custom length pushrods are NOT needed!! Jim Lapikas told me ( before he got silly ) that these longer Comp Cams push rods were a match for the longer length valves. Everything seems to be good here. ARP screw in studs - Comp Cams guide plates - Comp Cams roller tip rockers - Edelbrock valve springs.

I installed the Edelbrock Performer RPM intake manifold using ARP 12 point stainless bolts. Another mild headache here, but I prevailed. The ARP bolts are great, but the runner size/casting is larger than stock, so bolt head clearance is an issue on (2) bolts. On (1) of the bolts, I had to grind down my 3/8" 12 point box end wrench on the grinder to get the bolt tight ( no big deal - I used my Harbor Freight wrench 🤣 ). On the 2nd bolt, It required a lot more effort... I had to grind the ARP bolt head flange down with my bench grinder, shorten the bolt 3/16", grind the washer down, and grind the runner on my freshly coated intake. Luckily it's on the back side of the runner, and since the intake is silver, you can hardly even tell. Geezzz!

I installed the March billet oil filler tube. I used a few drops of oil on the tube, and a block of wood wrapped in a towel, and tapped it into the block using a dead blow hammer.

AC Delco temp sensor, Robert Shaw thermostat, thermostat housing are all installed onto the intake manifold.

So here is where I'm at...

On another note. I have gotten a flush mount bezel for the Holley 3.5" screen. I will flush mount this bezel into my center dash bezel. The overall size of the bezel's flange was too big, but I knew I could customize this to fit by trimming the flange around the bezel.

(10) mimutes on the bench grinder, and a quick block sand, and I'm pretty close... My bezel is warped, so I'm waiting on a replacement from Kevin to get here from Canada, to finish this out.

Last edited: